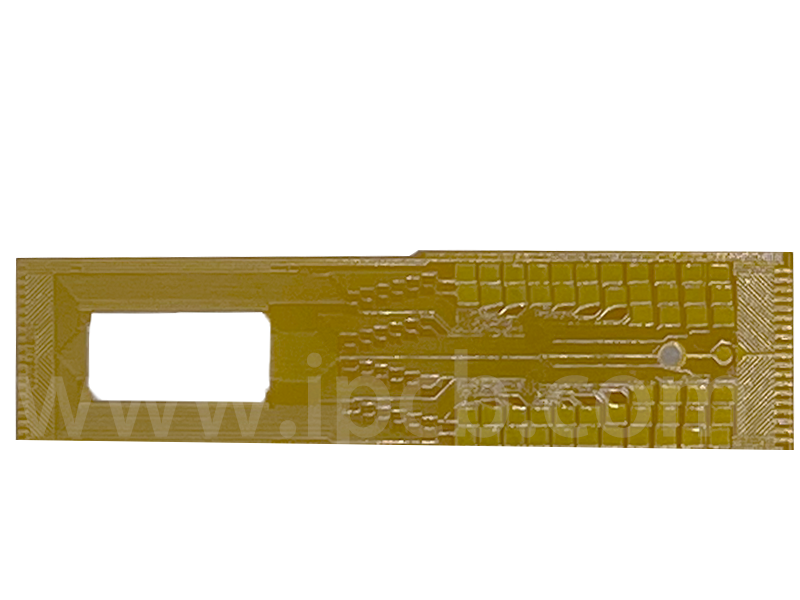

Name: FPC hollow board/Hollow FPC

Substrate: polyimide

Thickness: 0.3mm

Layer: 2 layers

Copper thickness: 6 OZ pure copper 1mil PI 25um AD

Line width/spacing: 0.15mm/0.15mm,

Form factor tolerance: ±0.1mm

Surface treatment: immersion tin

What is FPC hollow board? It is one of the products of flexible circuit boards, which is a kind of highly reliable and excellent flexible printed circuit boards manufactured with basic materials such as polyimide or polyester film.

FPC hollow board is also known as False Double-sided Flexible Circuit Board, FPC Cutout Board, Flexible Cutout Board and so on. Openwork FPC is a special board type of single panel in terms of the number of conductor layers, and has many aliases, such as single-copper double-dozen boards, false double-sided boards and so on. Openwork board product structure is mainly to supplement the shortcomings of the single panel, single panel due to the limitations of the soft board material, more than a single-sided connection function, if there is a line design only a single layer of the line, but the connection needs to be double-sided point of contact, then, openwork board is the best choice, one can reduce the use of single-panel folding caused by the dependence on the assembly problems, and secondly, to increase the density of the composition and reduce the cost of procurement of double-sided production of the board problem.

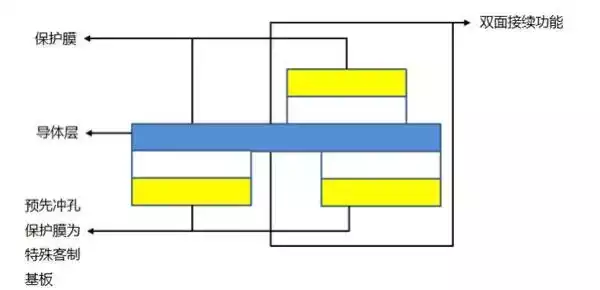

Due to institutional design constraints, in the low-density assembly of single-layer lines, it is necessary to use two-sided assembly design, because of single-panel material limitations, to make the double-sided successive assembly of its difficulties, if the double-sided panels through-hole plating, to overcome the double-sided lines is not a problem, but if the application is applied to the dynamic application of double-sided panels of the flexural characteristics of a single panel than the difference between the structure of the hollow plate came into being, the use of the pre-punched holes in the protective film and the copper foil. The use of pre-punched protective film and copper foil combined to form a special custom substrate design of the single-panel structure, and then in the pre-punched area of the necessary protection in order to complete the production of the line, the skeleton board side view of the structure can be referred to in the following figure:

FPC hollowing board features

Only one layer of alignment, can be assembled on both sides of the components, both sides need to open the window with a pad.

No through-hole, this time you can choose to use the FPC hollowing board, also known as the false double-sided board

Can be added to the auxiliary materials have a supporting role (3M adhesive, steel reinforcement, PI reinforcement, FR4 reinforcement)

Copper thickness of 1OZ, 2OZ, 3OZ, 6OZ CU can be selected, the surface treatment: Immersion tin / immersion gold

Minimum line width line spacing is 0.1mm, the default colour of FPC is yellow, can also have white, black, green.

Can not do impedance control, this type of product is mostly used in printer cartridges, LCD screen, etc.

FPC hollow board production process:

1. Cutting: According to the required size of the substrate for the initial cutting, the size is required to be correct and its surface should not have creases, stains, etc..

2.CNC drilling: according to the size and shape of the holes or patterns in the design drawings, the plate is drilled at high speed.

3. Copper plating: use the principle of precipitation precipitation chemical copper on the surface of the substrate and copper holes in the surface of a thin layer of copper, and check its thickness, the copper plating should be uniform and smooth. And appropriate chemical rinsing, the surface of the easy to remove.

4. Paste dry film.

5. Both sides of the exposure: the semi-finished FPC hollow board placed under certain conditions of light conditions to detect whether there are pinholes broken lines and so on.

6. Develop: show the image of the negative.

7. Etching: remove oxides and impurities on the surface of the hollow plate, enhance the copper and surface adhesion.

8. Remove the film and chemical cleaning: will be affixed to the dry film more than part of the removal.

9. Apply protective film: the protective layer on the surface of FPC hollow board.

10. Lamination: make the film affixed more firmly affixed to the surface of the FPC hollow board.

11. Plating lead or nickel gold: some need to increase the special features of the FPC hollow board need to be plated with this metal to achieve.

12. Dividing and punching shape: deal with the appearance of the FPC hollow board, whether there is burr, pulling material and other appearance of bad phenomena.

13. Testing: The FPC hollow board will be made to test and compare with the standard samples, whether its appearance and performance are consistent.

FPC hollow board is widely used in mobile phones, computers and LCD screens, CD Walkman and other products. Of course, there are advantages at the same time, FPC hollow plate itself also has certain shortcomings. First of all, its production process is complex, involving a very large number of process steps, which also means that the production time is long. Secondly, along with the development of electronic technology, especially in the wide application of large-scale integrated circuits in such a background, Hollow FPC with high density of fast, high precision, high number of changes in the direction of the fine lines.

Name: FPC hollow board/Hollow FPC

Substrate: polyimide

Thickness: 0.3mm

Layer: 2 layers

Copper thickness: 6 OZ pure copper 1mil PI 25um AD

Line width/spacing: 0.15mm/0.15mm,

Form factor tolerance: ±0.1mm

Surface treatment: immersion tin

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.