FPC is also known as flexible circuit board, FPC PCBA assembly soldering process is very different from the assembly of rigid circuit boards, because the hardness of the FPC board is not enough, more flexible, if you do not use a special carrier board, it is impossible to complete the fixing and transmission, and can not complete the printing. Paste. Through the furnace and other basic SMT processes.

1.FPC pre-treatment

FPC board is relatively soft, the factory is generally not vacuum packaging, in the transport and storage process is easy to absorb moisture in the air, the need for SMT casting line before the pre-baking process, the moisture will be slowly forced out. Otherwise, under the impact of the high temperature of the reflow soldering, FPC absorbed moisture quickly gasification into water vapour protruding FPC, easy to cause FPC delamination. Blistering and other bad.

Pre-baking conditions are generally temperature 80-100 ℃ time 4-8 hours,under special circumstances, the temperature can be adjusted to 125 ℃ or more, but need to correspondingly shorten the baking time. Before baking, must first make a small sample test to determine whether the FPC can withstand the set baking temperature.When baking,the FPC should not be stacked too much, 10-20PNL is more suitable. After baking, the FPC should have no obvious discolouration. Deformation.Warp and other defects, need to be qualified by IPQC sampling before the line.

2.FPC special carrier board production

According to the circuit board CAD file,read the FPC hole positioning data to create high-precision FPC positioning templates and special carrier boards,positioning templates on the diameter of the positioning pins and carrier board positioning holes on the positioning holes on the FPC hole diameter match.Many FPC because of the need to protect part of the line or design reasons is not the same thickness,some places thick and some places to thin, some have to strengthen the metal plate, so the combination of carrier plate and FPC need to be processed according to the actual situation of sanding and grooving,the role of printing and mounting to ensure that the FPC is flat.

Carrier plate material requirements of lightweight. High strength. Low heat absorption. Fast heat dissipation and small warpage and deformation after many thermal shocks.Commonly used carrier materials include synthetic stone.Aluminium plate. Silicon plate. Special high temperature resistant magnetised steel plate.

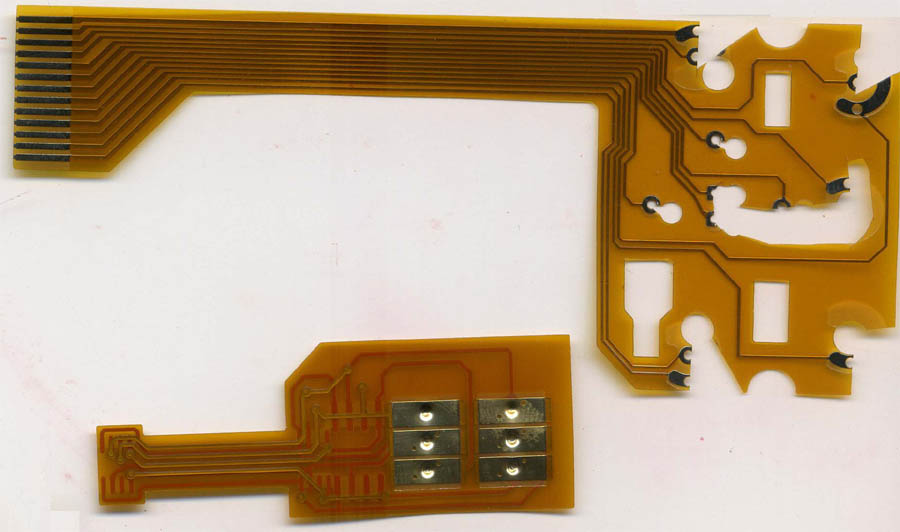

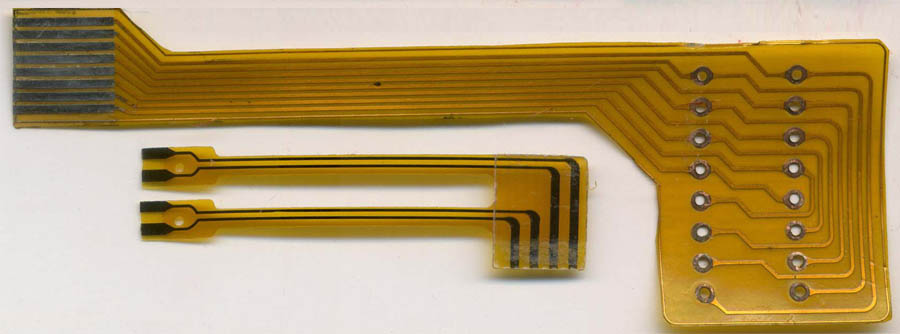

FPC

3. Production process

We are here to take the ordinary carrier board as an example to describe the SMT key points of FPC, the use of silicone boards or magnetic fixtures, FPC fixed to a lot more convenient, do not need to use tape, and printing. Paste. Soldering and other process points are the same.

3.1.FPC fixed

Before SMT, the first need to accurately fix the FPC on the carrier board. Particular attention should be paid to, from the FPC fixed on the carrier board and then, to print. The shorter the storage time between mounting and soldering, the better.Carrier boards are available with or without locating pins. Carrier plate without locating pins should be used with locating template with locating pins.Firstly,put the carrier plate on the locating pins of the template so that the locating pins are exposed through the locating holes on the carrier plate,put the FPCs on the exposed locating pins one by one and fix them with adhesive tapes, then let the carrier plate and the locating template of the FPCs be separated to print, paste and solder.Paste and solder.

The carrier board with positioning pins has been fixed with a number of spring locating pins of about 1.5mm in length,so that the FPC can be put one by one directly on the spring locating pins of the carrier board, and then fixed with adhesive tape. In the printing process, the spring locating pins can be completely pressed into the carrier plate by the stencil,and the printing effect will not be affected.

Method 1 (single-sided tape fixing) with a thin high-temperature resistant single-sided tape to fix the four sides of the FPC on the carrier board, do not let the FPC have offset and warpage, the viscosity of the tape should be moderate, after reflow soldering must be easy to peel off, and no residual adhesive on the FPC. If you use automatic tape machine, can quickly cut the length of the tape, can significantly improve efficiency, cost savings, to avoid waste.

Method 2 (double-sided tape fixing) first use high temperature resistant double-sided tape on the carrier board, the effect is the same as the silicone board, and then stick the FPC to the carrier board, pay special attention to the viscosity of the tape can not be too high, otherwise it is easy to cause tearing of the FPC after reflow soldering when peeled off. The viscosity of the double-sided tape will gradually become lower after repeated passes through the furnace, and must be replaced immediately when the viscosity is so low that the FPC cannot be fixed reliably.

This station is the most important station to prevent FPC from being dirty, and it is necessary to wear finger cots to work. Before reusing the carrier board, it should be cleaned properly, either with a non-woven cloth dipped in cleaning agent, or with an anti-static dust roller to remove surface dust, tin beads and other foreign matter. You can also use an anti-static dust roller to remove surface dust, tin beads and other foreign objects. Do not use too much force when putting FPC, FPC is fragile and easy to produce creases and breakage.

3.2. FPC solder paste printing

FPC on the composition of the solder paste is not very special requirements, the size of the tin ball particles and metal content to the FPC with or without fine pitch IC as standard, but the FPC on the solder paste printing performance requirements are higher, the solder paste should have excellent thixotropy, solder paste should be able to easily print off the mould and can be firmly attached to the surface of the FPC, will not appear off the mould is bad, blocking the stencil leakage holes or printing after the collapse of the bad. There will not be any defects such as poor mould release, blocking stencil leakage holes or collapsing after printing.

Because the carrier board is loaded with FPC, FPC has a high temperature tape for positioning, so that its plane is not consistent, so the printing surface of FPC can not be as flat as PCB and the thickness of the same hardness, so it is not appropriate to use a metal squeegee, but should be used in the hardness of 80-90 degrees of polyurethane squeegee. The best solder paste printing machine with optical positioning system, otherwise there will be a greater impact on the printing quality, although the FPC is fixed on the carrier board, but the FPC and the carrier board will always produce some small gaps between them, which is the biggest difference with the PCB hardboards, and囙setting parameter setting will also have a greater impact on the printing effect.

Printing station is also a key station to prevent FPC pollution, you need to wear finger cots to work, and at the same time to maintain the cleanliness of the station, wipe the stencil diligently, to prevent solder paste contamination of FPC gold fingers and gold-plated keys.

3.3. FPC Lamination

According to the characteristics of the product. The number of components and the efficiency of the paste, the use of medium. High-speed mounting machine can be mounted. Since there is an optical MARK mark for positioning on each FPC, there is little difference between SMD mounting on FPC and PCB mounting. It should be noted that, although the FPC is fixed on the carrier board, but its surface can not be as flat as the PCB hardboard, FPC and the carrier board there will be local gaps between, so the nozzle drop height, blowing pressure, etc. need to be set accurately. Blowing pressure etc. need to be set accurately, and the speed of suction nozzle movement needs to be reduced.

3.4. FPC reflow soldering

Should use forced hot air convection infrared reflow soldering furnace, so that the temperature on the FPC can be more uniform change, reduce the generation of bad soldering. If the use of single-sided tape, because it can only fix the four sides of the FPC, the middle part of the state of deformation due to the hot air, the pad is easy to form a tilt, molten tin (liquid tin at high temperatures) will flow and produce empty soldering. Continuous soldering. The soldering beads will cause high defective rate of the process.

3.4.1 Temperature Curve Test Methods

Due to the different heat absorption of the carrier board, the different types of components on the FPC,they are heated in the reflow process, the speed of temperature rise is different, the amount of heat absorbed is also different, so carefully set the temperature curve of the reflow oven, the quality of the soldering has a great impact. A more secure method is to be based on the actual production of the carrier board interval, in front of and behind the test board each put two pieces of carrier board with FPC, while the test carrier board FPC pasted with components, with high-temperature soldering wire to test temperature probe soldered to the test point, and at the same time with high-temperature-resistant adhesive tape to fix the probe lead on the carrier board.

Note that the temperature-resistant tape should not cover the test point. The test point should be selected near the solder joints and QFP pins on each side of the carrier board, so that the test result can better reflect the real situation.

3.4.2 Temperature Curve Setting

In the furnace temperature debugging, because the FPC temperature is not good, so it is best to use the temperature curve pipeline warming / warming / reflux, so that the parameters of the temperature zone is easier to control, in addition to the FPC and the components by the thermal shock of the impact of the smaller. According to experience, it is best to adjust the furnace temperature to the lower limit of the value of the solder paste technology requirements, the reflow furnace wind speed is generally the lowest wind speed that can be used in the furnace, reflow furnace chain stability should be good, there can be no jitter.

3.5.FPC inspection. Test and board

As the carrier plate in the furnace heat absorption, especially aluminium carrier plate, out of the furnace temperature is higher, so it is best to add a new strong cooling fan in the furnace outlet to help quickly cool down. At the same time, workers need to wear heat-insulating gloves to avoid being burned by the high-temperature carrier plate. When removing the finished FPC from the carrier board, the force should be even, not brute force, so as to avoid the FPC being torn or creased.

Put the removed FPC under a magnifying glass of more than 5 times for visual inspection, focusing on checking the surface glue residue. Discolouration. Gold finger staining. IC pin soldering. IC pin soldering. Since the surface of FPC can not be very flat, so AOI misjudgment rate is very high, so FPC is generally not suitable for AOI inspection, but with the help of special test fixtures, FPC can be completed ICT.FCT test.

Since FPC is mostly used for joint boards, it may be necessary to do board splitting before ICT.FCT test, although the use of blades, scissors and other tools can also complete the board splitting. Although the use of tools such as blades, scissors, etc. can also complete the work, but the work efficiency and quality of work is low. If the mass production of shaped FPC, can make a special FPC stamping board mould, stamping division, can greatly improve the efficiency of the work, while stamping out of the FPC edges neat and beautiful, stamping and cutting the board produced by the internal stress is very low, you can effectively avoid solder joints tin cracks.

In the PCBA flexible electronic assembly welding process, the precise positioning and fixation of the FPC is the key point, the key to fix the good or bad is to make the right carrier board. Next is the FPC pre-baking. Printing. Paste and reflow. Obviously FPC SMT process is much more difficult than the PCB hardboard, so the precise setting of process parameters is necessary, at the same time, strict production process management is equally important, must ensure that the staff to strictly implement the SOPs on each of the provisions of the follow-up engineers and IPQC should strengthen the inspection, and timely discovery of abnormalities in the production line, analyse the reasons and take the necessary measures in order to FPCSMT In order to control the defective rate of FPC SMT production line within dozens of PPM.

FPC

4.PCBA production equipment

The basic equipment needed for PCBA production are solder paste printing machine. Paste machine. AOI inspector. Component clipper. Wave soldering. Tin furnace. ICT test fixture, FCT test fixture. Aging test stand, etc.

4.1. Solder Paste Printing Machine

Modern solder paste printing machine generally consists of mounting plate. Adding solder paste. Embossing. Conveyor board and other mechanical components. Its working principle is to fix the PCB to be printed on the printing positioning table, then the left and right squeegees of the printing machine will print the solder paste or red glue through the steel mesh on the corresponding pads, and then the PCB with even leakage will be inputted into the laminating machine through the transmission table to carry out automatic lamination.

4.2. Mounter

SMD machine is also known as ‘SMD machine’, ‘Surface mounting system’, ‘Surface mounting system’, ‘Surface mounting system’, ‘Surface mounting system’. ‘Surface Mount System’ (SurfaceMountSystem), in the production line, it is put aside after the solder paste printing machine, is through the movement of the mounting head to accurately place the surface mounted components on the PCB pads of a device, divided into two kinds of manual and fully automatic.

4.3 Reflow Soldering

Reflow soldering internal heating circuit, the air or nitrogen heated to a sufficiently high temperature after blowing to the circuit board has been affixed components, so that the components on both sides of the solder melted and bonded with the motherboard. The advantage of this process is that the temperature is easy to control, the soldering process can also avoid oxidation, manufacturing costs are also easier to control.

4.4. AOI Inspection System

AOI (AutomaticOpticInspection) is the full name of the automatic optical inspection, is based on the principle of optics to the common defects encountered in the production of welding inspection equipment. The machine automatically scans the PCB through the monitor, collects the image, compares the tested solder joints with the qualified parameters in the database, detects the defects on the PCB through image processing, and shows/marks the defects through the display or the automatic sign for the maintenance personnel to repair.

4.5. Component Cutter

Used to cut and deform the pin components.

4.6. Wave Soldering

Wave soldering is to let the soldering surface of the insert board contact with the high temperature liquid tin directly to achieve the purpose of soldering, its high temperature liquid tin keeps a slanting surface, and the liquid tin forms a wave-like phenomenon by the special device, so it is called ‘Wave Soldering’, and its main material is the solder bar.

4.7. Soldering Furnace

Generally, a soldering furnace is a soldering tool used in electronic soldering. For discrete components circuit board welding consistency, easy to operate. Fast. High efficiency.

4.8. Board washing machine

Used for PCBA board cleaning, can remove the residue of the board after welding.

4.9.ICT Test Fixture

ICTTest is mainly a test probe contact PCB layout out of the test point to detect the PCBA line open. Short circuit. All parts of the welding situation

4.10.FCT Test Fixture

FCT (Functional Test) which refers to the test target board (UUTUnitUnderTest) to provide an analogous operating environment (excitation and load), so that it works in a variety of design states, so as to obtain the parameters of the various states to verify the functionality of the UUT good or bad test method. Simply put, the UUT is loaded with appropriate excitation to measure whether the output response meets the requirements.

4.11. Aging Test Rack

The aging test rack can be used to test PCBA boards in batch, through long time and other operations similar to the user to test out the problematic PCBA boards.

iPCB Circuit has its own SMT factory and PCB,FPC factory, providing PCBA, FPC one-stop OEM service. Our products are related to automotive electronics, medical equipment, industrial control, aerospace, communication equipment and other fields.