Flexible Printed Circuit Board (FPCB),abbreviated as FPCB,is the abbreviation of Flex-PCB, sometimes called FPC.Flexible Printed Circuit Board (FPC), is a kind of circuit board that adopts flexible substrate, (such as polyimide film, polyester film, etc.) as the substrate, and prints or adheres to the substrate with the functional parts such as conductors, fine wires, etc. through a special manufacturing process. Adhesion on the substrate composition of the circuit board. Compared with traditional rigid circuit boards, FPC has better bendability, expandability, light weight, small size and other advantages, suitable for use in the weight and volume of limited scenarios. FPC and PCB are similar in function and structure, while PCB (Printed Circuit Board) usually refers to the rigid circuit board.

Both FPCs and PCBs are designed with copper-clad circuits on both the surface and inner layers for transmitting electronic signals. The biggest difference between the two is the material of their substrates; PCB's substrate is similar to glass, making it hard and rigid, while FPC's substrate is similar to paper,which is soft and bendable on a flat surface.

The structure of FPC?

Substrate Layer: The substrate layer of FPC is made of flexible insulating materials, commonly used are polyester films (e.g. polyester sheet PET) and polyimide films (PI films). These materials are highly flexible and have high tensile strength.

The base layer provides strength and flexibility, allowing the FPC to be bent, folded or adapted to complex shapes. The protective layer provides protection and isolation.

Metal Layer: The conductive metal layer on the FPC is generally copper foil, usually between 0.009mm and 0.072mm thick. Copper foil is attached to the substrate layer, through a special chemical etching and etching process, it will be etched into the design of the required wires, electrodes and other shapes.

The wire lines in the metal layer connect the electronic components and play a role in transmitting signals and currents.

Protective layer: In order to protect the wire layer, FPC is usually coated with a protective layer, commonly used protective layer materials such as polyester resin, polyurethane and so on. The protective layer not only protects the wire layer from damage, but also prevents oxidation, corrosion and other environmental factors.

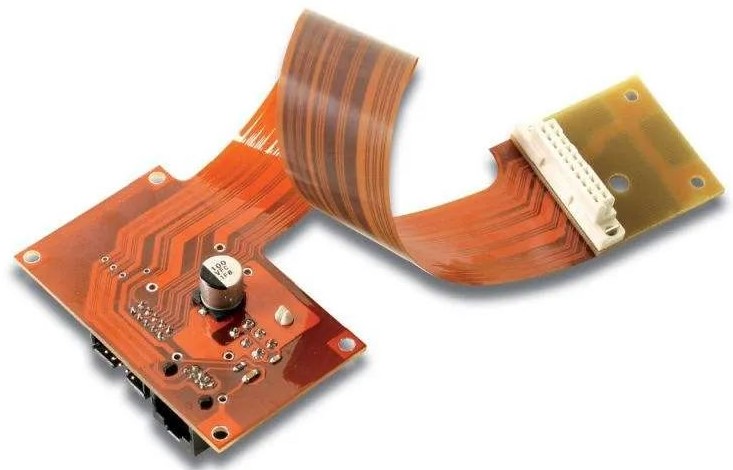

FPC

What are the characteristics of FPC?

FPC is characterized by its lightness, thinness, windability and ease of bending, which become its advantages and uniqueness. Therefore, it is especially suitable for products that have limited space and are unable to fulfill all design requirements with a single rigid PCB.

Some products may need to make full use of the limited space inside and stack multiple PCBs on top and bottom, so they need FPCs that can be bent to connect.

Some may need to use a flexible board to connect other PCBs at a distance for signaling in order to save boards, while others may need some PCBs to be crossed with other PCBs vertically or at different angles.

Generally speaking, FPC above is not suitable for the design of complex lines and soldering precision electronic parts, because:

1.soldering electronic parts of the solder in the easy to bend the FPC is easy to break.

2.compared to the PCB, FPC is less resistant to high temperatures. Easily arch or peel at high temperatures.

3.FPC welding precision than PCB difficult to control, because it uses PI film (you can first think of it as a film similar to plastic bags), and PI film welding pads open window will generally use the knife mold stamping, and then attached to the film in the FPC, the accuracy of screen printing than the PCB to poor, that is, the open window is easy to offset, not flat.

4.FPC is not suitable for the design of multi-layer copper-clad circuit. When the number of layers of copper-clad circuits increases, FPC will become harder, and its bending ability will also be weakened, so that the main advantage of FPC is low. At the same time, in order to make accurate solder pads, it may be necessary to use more advanced laser technology to make windows on the P-film mold, which will increase the cost.

However, we can still see that some people can be able to paste and solder some precision electronic parts on the FPC, for example, there are a lot of such products in the digital camera, which is how to realize?

In fact, to do this is not difficult, just need to weld precision parts in the FPC need to stick the back of a piece of rigid reinforcement plate (stiffener) on it, however, so in the position of the reinforcement plate can only be single-sided welding parts, because the reinforcement plate is no circuit, just pure strength support, however, the cost of this FPC must be much higher than the general FPC.

Flexible circuit board as an important electronic component, is the support body of electronic components, with flexible, thin, light weight, small weight, foldable and other characteristics, is gradually in consumer electronics, communications, automotive electronics, medical equipment and other fields are widely used.