General pcb board are produced when designing and developing electronic products. Due to the need for some experiments, the speed of manufacturers making PCB boards is too slow, and it is also convenient to replace them during the experimental stage.

General pcb board and communication boards are indispensable and important components of electronic equipment. They play a connecting role between electronic components, providing a stable working environment and a platform for signal transmission for the circuit. The role and function of general pcb board and communication boards will be introduced in detail below.

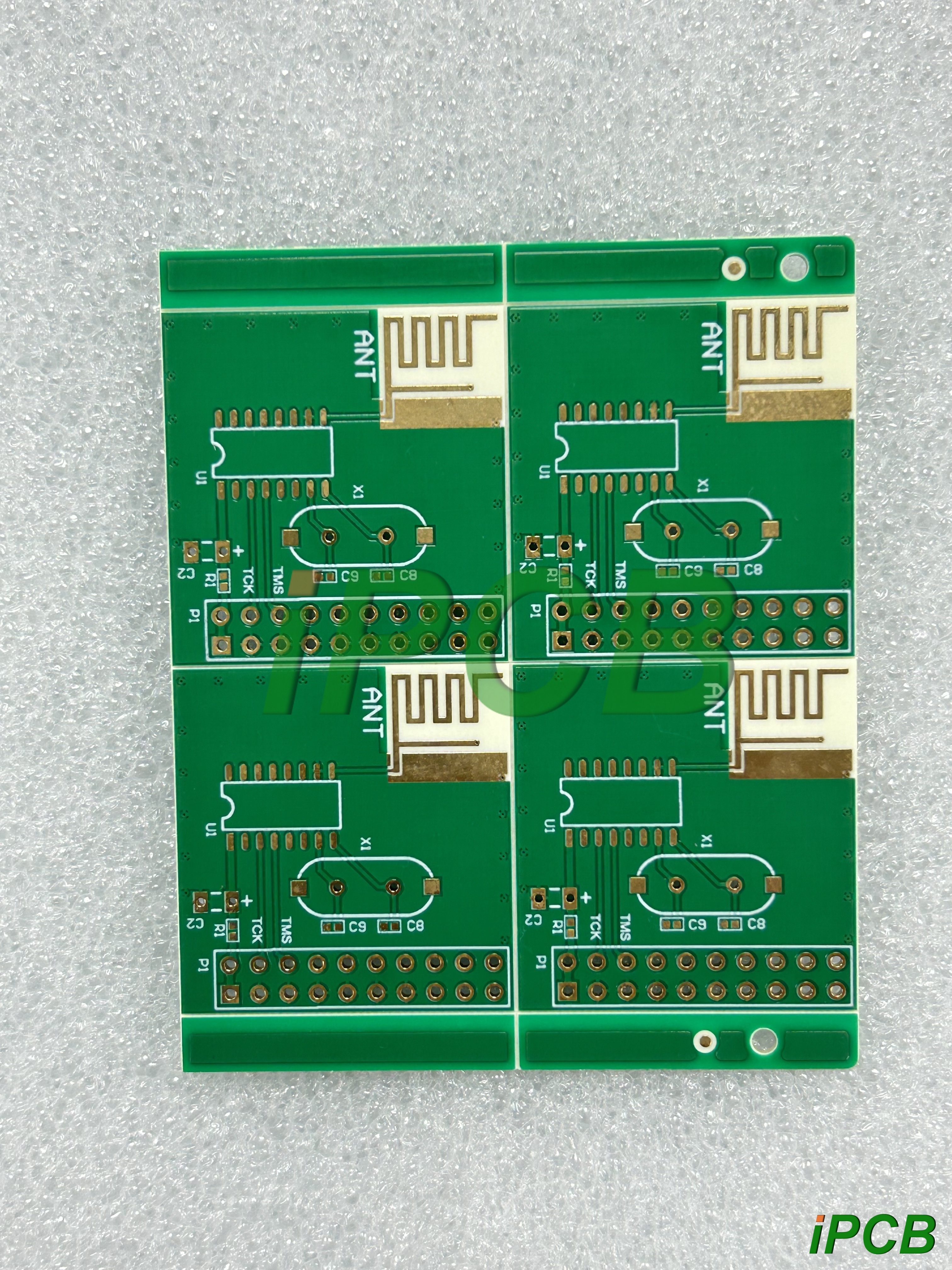

general pcb board, that is, printed circuit boards, are circuit boards made of conductive materials and made by electronic processes. general pcb board are widely used in various electronic devices, including mobile phones, televisions, computers, etc. It is one of the key components for connecting and supporting electronic components. There are layers of wires and electronic components on the universal PCB board. Through the connection between these wires and components, the transmission and control of signals in the circuit are realized. The manufacture of general pcb board uses advanced processes and technologies to ensure its quality and reliability.

The role of general pcb board

The role of general pcb board in electronic equipment is very important. First of all, it provides a connection between electronic components. In electronic devices, there are a large number of electronic components that need to be connected to each other. Through the wires on the universal PCB board, these components can be connected together to form a complete circuit. Secondly, the universal PCB board provides a stable working environment for electronic devices. The material and process manufacturing of the PCB board ensure its stability and reliability, and can effectively reduce interference and noise in the circuit. In addition, the universal PCB board can also provide good heat dissipation to prevent electronic components from being damaged by overheating. Finally, the universal PCB board can also simplify the repair and upgrade of electronic equipment. If a component in an electronic device fails, only the corresponding universal PCB board needs to be replaced, without the need to redesign and manufacture the entire circuit.

What is the difference between a general pcb board and a custom circuit board?

Different design purposes

General pcb board: designed to meet the general needs of a variety of different electronic devices or systems, with high versatility and compatibility. For example, some universal microcontroller development boards can be used for a variety of different types of microcontroller experiments and simple project development, and can adapt to a variety of chips and peripherals.

Customized circuit boards: are specially designed for specific electronic devices or systems to meet their unique functions, performance, size, shape and other requirements. For example, the motherboard of a smartphone is customized according to the overall design, functional module layout and performance indicators of the mobile phone to realize various complex functions of the mobile phone.

Different functional characteristics

General circuit board: usually has basic circuit functions and interfaces, and can expand functions by connecting different modules or chips. However, due to the need to take into account multiple applications, its functions are relatively basic and universal, and may not meet the high-precision and high-integration requirements of certain specific devices for functions.

Customized circuit board: It can integrate specific functional modules according to the needs of specific devices to achieve a high degree of functional integration and optimization. It can be specially designed for specific signal processing, data transmission, power management and other functions to achieve the best performance.

Different size and shape

General circuit board: generally adopts standard size and shape to facilitate mass production and use in different devices. Common ones are standard rectangular circuit boards with sizes such as 9cm×6cm, etc., and their layout and mounting hole positions also follow certain standard specifications.

Customized circuit board: Its size and shape are designed entirely according to the internal space and structure of a specific device. It can be an irregular shape or a special size such as ultra-thin, ultra-small or ultra-large to better adapt to the device's shell and internal structure requirements.

Cost difference

General circuit board: Because it can be mass-produced and the design is relatively standardized, its production cost is relatively low. At the same time, because there are more suppliers and mature products in the market, the procurement cost is also relatively reasonable.

Customized circuit board: More manpower, material resources and time are required in the design and production process, including special design and development, customized production process and smaller production batches, so the cost is usually higher.

Difference in production cycle

General circuit board: The production process is mature, there are ready-made production processes and molds, etc., and the production cycle is relatively short. In general, it may only take a few days to a few weeks from ordering to delivery, depending on the order quantity and the supplier's production arrangements.

Customized circuit board: Because it requires preliminary design, review, sample production and debugging, the production cycle is long. It may take weeks or even months from the beginning of design to the final mass production.

In summary, general circuit boards have become an ideal choice for getting started and quickly landing electronic projects with their high cost performance, fast delivery and wide compatibility. Whether it is the creative experiment of electronic enthusiasts or the small trial production needs of enterprises, general circuit boards can help projects go smoothly with stable and reliable performance.

Choosing iPCB's general pcb boards means choosing peace of mind, high efficiency and quality. We look forward to working with you to light up every innovative electronic dream with standardized excellent products! Contact us now to start a convenient electronic manufacturing journey!