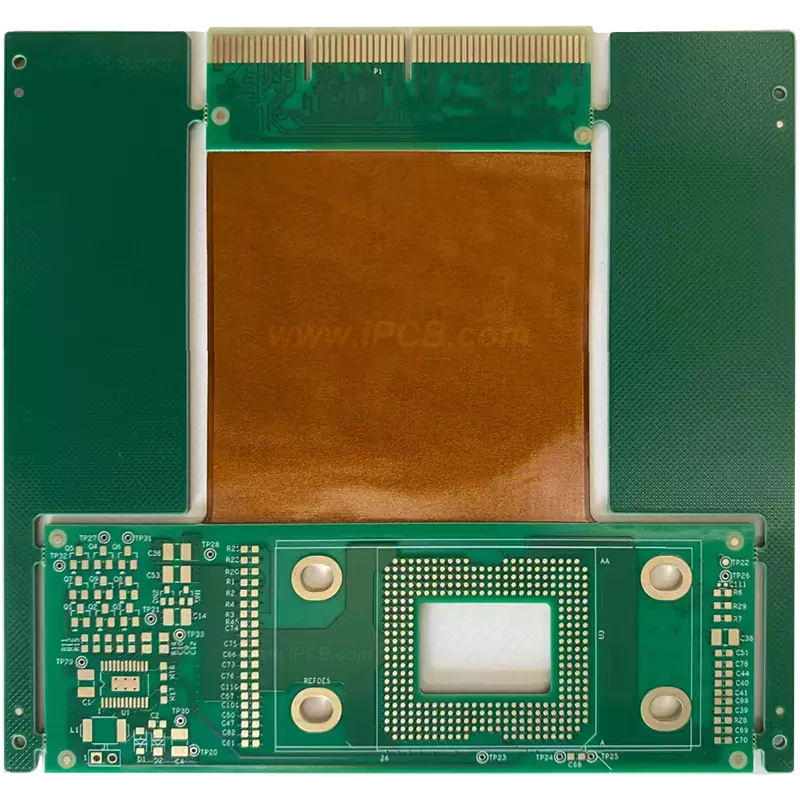

Product Name: Golden Finger Rigid-Flex PCB

Substrate: FR4+PI

Stacked structure: FR4 4L+FLEX 2L

FPC thickness: 0.15mm

Finished thickness: 1.2mm

Copper thickness: 1oz (35 μ m)

Surface treatment: ENIG + Golden Finger

Minimum line width/spacing: 4mil/4mil

Stack-up: 2+2+2 HDI PCB

Minimum aperture: machine drill: 0.2mm, laser drill: 0.1mm

Product application: Communication products

The manufacturing process of Golden Finger Rigid-Flex PCB is prone to deviation of the gold finger during CNC, resulting in the distance from the gold finger to the edge exceeding the tolerance range. We have preset optical points and laser secondary forming technology for the inner layer of the soft board, which can effectively improve the problem of gold finger deviation and control the deviation tolerance within ± 0.05mm, greatly improving the first pass yield of the product.

However, with the rapid development of electronic products, the precision of Rigid-Flex PCB is increasing, and customers have also put forward higher requirements for the dimensional accuracy of gold fingers. The tolerance of ± 0.05mm from the gold finger to the board edge has become the norm in the industry. Using conventional CNC shape processing can easily cause gold finger offset, low yield, and difficult to meet quality requirements. Therefore, there is an urgent need to solve such problems through process optimization.

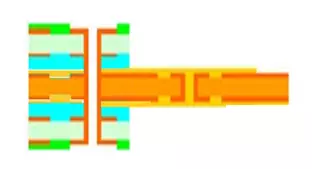

Stack-up of Rigid-Flex PCB

With the conventional CNC milling shape, the overall dimensional accuracy of the golden finger end of the Golden Finger Rigid-Flex PCB can be controlled within ± 0.1mm, but the distance from the golden finger to the edge is measured using the anime method. It is found that more than 50% of the boards have the golden finger offset problem, that is, the width of the golden finger ends is asymmetric, and the serious offset reaches 0.15-0.20mm, which cannot meet the customer's high-precision requirements for the processing of the golden finger.

To improve the offset of the golden finger, different shape processing methods are specially designed to compare the offset degree of the golden finger. Due to the influence of its own structure, the rigid flex joint plate with golden fingers is still inside the hard plate after V-CUT, making it impossible to test it. Therefore, it is necessary to optimize the original shape file to three times molding. The first time pre sizing the soft board and the shape of the gold finger, retaining the top connection position of the gold finger, and exposing the gold finger after removing the cover for easy E-T testing.

After the inner layer of the gold finger is uncovered, the gold finger area is precision machined using optical point grabbing and secondary laser forming technology to ensure its dimensional accuracy.

The use of secondary laser forming technology for processing flexible PCB areas and gold finger parts has the following benefits:

1. The inner layer of the soft board is designed with optical point positioning, which can maintain the same level of expansion and contraction as the inner layer's gold finger area.

2. By utilizing the high precision and automatic expansion and contraction function of laser processing itself, the precision of finger to edge dimensions and the consistency of processing are guaranteed.

3. Using laser to synchronously process the flexible area can effectively remove burrs on the soft board, reduce manual repairs, and greatly improve production efficiency and quality.

After the testing is completed, the external process is transferred to CNC milling, and the third molding only processes the hard plate area and the top of the gold finger.

Through testing, it has been found that the use of FPC inner layer preset optical points and laser secondary molding process can effectively improve the gold finger offset problem of Rigid-Flex PCB, control the offset tolerance within ± 0.05mm, greatly improve the first yield of the product, and fully meet the high-precision requirements of customers for Golden Finger Rigid-Flex PCB processing.

Product Name: Golden Finger Rigid-Flex PCB

Substrate: FR4+PI

Stacked structure: FR4 4L+FLEX 2L

FPC thickness: 0.15mm

Finished thickness: 1.2mm

Copper thickness: 1oz (35 μ m)

Surface treatment: ENIG + Golden Finger

Minimum line width/spacing: 4mil/4mil

Stack-up: 2+2+2 HDI PCB

Minimum aperture: machine drill: 0.2mm, laser drill: 0.1mm

Product application: Communication products

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.