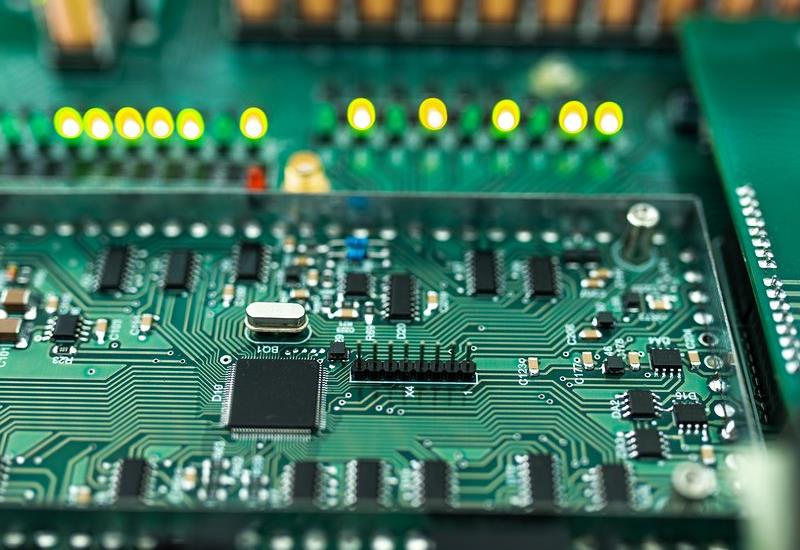

Green coating Construction for PCBA

PCBA's BGA bottom of the belly of the ball pads are ‘green paint limit’ pipeline to complete the soldering.Once the green paint is too thick (more than 1 mil) and the pad surface is too small, there will be a ‘crater effect’ which is not easy for wave soldering to enter.And the cut-off board of the ball planting work in a large number of flux and high heat attack,will force the solder penetrate into the bottom of the edge of the green paint,so that the green paint has the risk of floating away.This is very different from the PCB pad soldering. Usually, the SMD copper pads of this type of carrier boards are slightly larger (sometimes containing nickel gold inside), the green paint can climb up to the circumference of the 4 mil peripheral width, due to the inability to flow tin to the outer straight wall of the copper pads,so the strength of its stress is not as strong as all the copper pads formed by the NSMD solder joints.In addition,the stress of SMD solder joints is not easy to dissipate, resulting in their ‘fatigue life’ is generally only 70% of NSMD.In fact,the general packaging board designers and producers,this logic is still not quite understand,making the mobile phone PCB circuit board on a variety of BGA acceptor pads, the strength of lead-free soldering in the future will be more and more insecure.

1.PCB circuit board green coating plug hole

Usually the function of the green paint plug holes is for the PCB circuit board test, easy to draw the real space so that the board can be quickly fixed; Secondly, the first side of the through-hole near the line or solder pads, free from the second side of the wave soldering in the welling up of tin infringement.However,if the filler is not secure and breaks,it will still be subjected to the endless problems caused by tin spraying or wave soldering which forcefully presses in the tin slag. There are four methods of hole plugging listed in the original table,but they are not practical in mass production.

2.Re-wave soldering after PCBA soldering

When both sides of the completion of some parts of the welding,often need some components of the insertion of welding,resulting in the ball pad adjacent to the through-hole will also be wave soldering heat transfer to the first side, resulting in the bottom of the belly has been Reflow soldered by the ball foot, may be subjected to remelting,or even the formation of accidental cold soldering or open-circuit. At this time, we can use temporary Heat Shield and Wave Shield two kinds of external heat shield, in the BGA area of the upper and lower sides of the heat insulation.

3.Circuit board hole plugging and hole blocking construction

Green paint hole plugging construction methods:dry film cover holes,printing flooded holes, refers to the printing board surface into the holes in passing double-sided plugging refers to the front and back side of the special deliberately plugged holes, but the residual air will sometimes burst out of the high-temperature. Professional hole plugging means that the holes are deliberately plugged and cured with a special resin before printing the green lacquer on both sides. Either way, it's a difficult process that's not easy to perfect.As a result,OSP boards with green paint either before or after plugging do not work,and there are many cases of downstream failures.As the OSP after the front plugging will easily leave liquid in the slit and hurt the hole copper,and the baking of the back plugging will be unfavourable to the OSP film, it is really a dilemma.

1.Solder Paste Printing

The opening of the steel plate should be a trapezoidal shape with a narrow top and a wide bottom,so that it is easy to step on the foot and lift up the plate after printing without disturbing the solder paste.The metal portion of the commonly used solder paste accounts for about 90%, and the size of the solder particles should not exceed 24% of the opening to avoid blurring of the paste edges. The most commonly used paste for BGA assembly is 53 μm particle size, while CSP is 38 μm particle size.

For large BGAs with a pitch of 1.0-1.5mm, the thickness of the printed steel plate should be 0.15-0.18mm.For close-pitch BGAs with a pitch below 0.8mm,the thickness of the steel plate should be thinned to 0.1-0.15mm. The width-to-depth ratio of the openings should be maintained at about 1.5 to facilitate the placement of paste.For close-pitch pads,the corners of the openings should be rounded to reduce the seizing of solder particles.Once the width-to-depth ratio of the steel plate is less than 66%,the construction of the printing paste should be 2-3mil larger than the surface of the pad,so that the temporary adhesion before welding is better.

2.PCBA Hot Air Soldering

After 90 years of forced convection hot air has become the mainstream of Reflow,the more the heating section of the production line, not only easy to adjust the ‘temperature curve’, and production speed will be accelerated. Currently, lead-free solderers need to have more than 10 segments on average to facilitate the heating process (up to 14 segments). When the high temperature in the profile has exceeded the Tg of the board and is too long, it will not only soften the PCB circuit board, but also the Z expansion will cause the board to burst,resulting in disasters such as the inner layer of the circuit or PTH breakage.The flux in the solder paste must be above 130℃ to show activity, and its activity time can be maintained for 90-120 seconds. The average heat limit of each component is 220°C and should not exceed 60 seconds.