What are the precautions for layout of HDI high-frequency PCB board with guaranteed quality?

1. In order to manage the electromagnetic force field between the insulation material of the high-frequency PCB circuit board and adjacent layouts, appropriate consideration should be given to using high-performance insulation high-frequency PCB circuit board with strict insulation numbering according to level control. In order to reduce the return loss of the PCB, the corners of the transmission lines of the circuit board should also be considered appropriately and a 45 degree angle should be used.

2. During the high-frequency PCB layout process, the circuit board has a tapped inductor at the tip lead. It is necessary to prevent the use of all lead containing components. In addition, external installation components should be used in high-frequency backgrounds. At the same time, for signal via holes, it is necessary to prevent the use of via hole processing technology. If lead inductance is generated at the via hole, it is strictly prohibited to use via hole processing technology on sensitive board.

3. In order to avoid the generation of three-dimensional electromagnetic force fields on high-frequency PCB during PCB layout, the bottom layer of Haobo should be provided, and these layers should be connected together through model drilling and electroplating. The operation should be appropriate, and non-contact nickel plating or immersion plating should be used instead of HASL method, as the high weldability coating on the electroplated surface requires fewer leads, which helps reduce background pollution.

4. Due to the uncertainty of the thickness and insulation performance of the solder mask layer on high-frequency PCB circuit board, in order to avoid significant changes in electromagnetic force and radiation caused by the solder mask material covering the entire surface, the solder mask layer should use the electromagnetic force field as the solder mask layer as much as possible.

5. The essential meaning above is a high-frequency PCB circuit board with guaranteed quality. It is a matter of attention for Layout. Because choosing different materials and methods throughout the entire Layout process may affect the performance of the PCB circuit board, Layout is implemented. During the operation process, you should master the projects related to the things you care about and carry out the operations. At the same time, for many people who need to purchase, choosing to purchase from a high-frequency PCB circuit board merchant with good service can better ensure the quality of products and services.

IPCB is a high-tech enterprise specializing in the design, development, and production of high-end PCB circuit board. IPCB independently developed the industry's first automatic quotation and ordering system for PCB, with the goal of building an industrial 4.0 PCB intelligent factory through Internet plus, to provide customers with professional PCB technology and PCB production services.

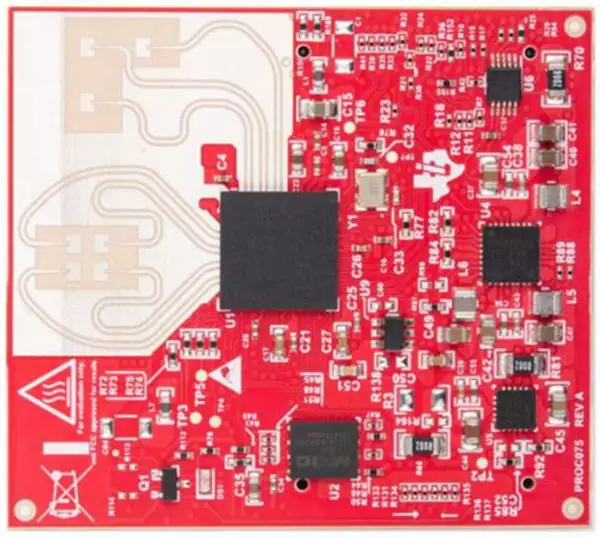

High frequency PCB

IPCB's independently developed PCB automatic quotation online ordering platform. It can achieve a series of functions such as real-time PCB quotation, ordering, payment, and after-sales service. Relying on the perfect Internet trading platform and the industry's first automatic quotation system, we can save customers' waiting time, shorten the research and development cycle from all aspects, and save time to market.

IPCB continuously strives to improve its PCB production process, making every effort to solve technical problems for customers, helping them win the market, constantly challenging technological peaks, and providing customers with more stable quality, higher performance products, and more satisfactory services.