The current development trend of wireless communication base stations is miniaturization, among which the requirement of the RF PCB power amplifier part is to reduce the PCB area under the premise of ensuring the unchanged transmission power. In order to meet the needs of miniaturization of power amplifiers, some RF PCB engineers will choose Tyconic's low-loss and high-dielectric constant PCB material RF-60, but RF-60 belongs to the polytetrafluoroethylene system and has a high processing cost.

In response to the needs of high dielectric constant applications in the wireless communication frequency band, Rogers, a supplier of RF circuit materials, launched RO4360G2, an RF PCB material with a dielectric constant of 6.15. It belongs to the RO4000 hydrocarbon resin/ceramic filler system, and its electrical performance is close to that of PTFE materials, while its processability is similar to that of FR-4 materials. It can replace Tyconic's RF-60 RF PCB material.

RO4360G2 RF PCB

RO4360G2 RF PCB material is a hydrocarbon resin ceramic-filled thermosetting material with a dielectric constant of 6.15, low loss, and glass fiber reinforcement, which can better balance its performance and processability. RO4360G2 expands Rogers' high-performance materials offering by providing RF PCB designers with a material that meets lead-free manufacturing requirements, enhances hardness to improve the processability of multi-layer RF circuit board structures, and reduces material and processing costs. RO4360G2 sheets are processed similarly to FR-4 and are suitable for automated placement. They have a low Z-axis thermal expansion coefficient, which increases product design flexibility, and RO4360G2 has a high glass transition temperature TG like all RO4000 series products. For multi-layer RF circuit board designs, RO4360G2 sheets can be mixed with RO4400 prepreg and other low dielectric constant RO4000 series materials.

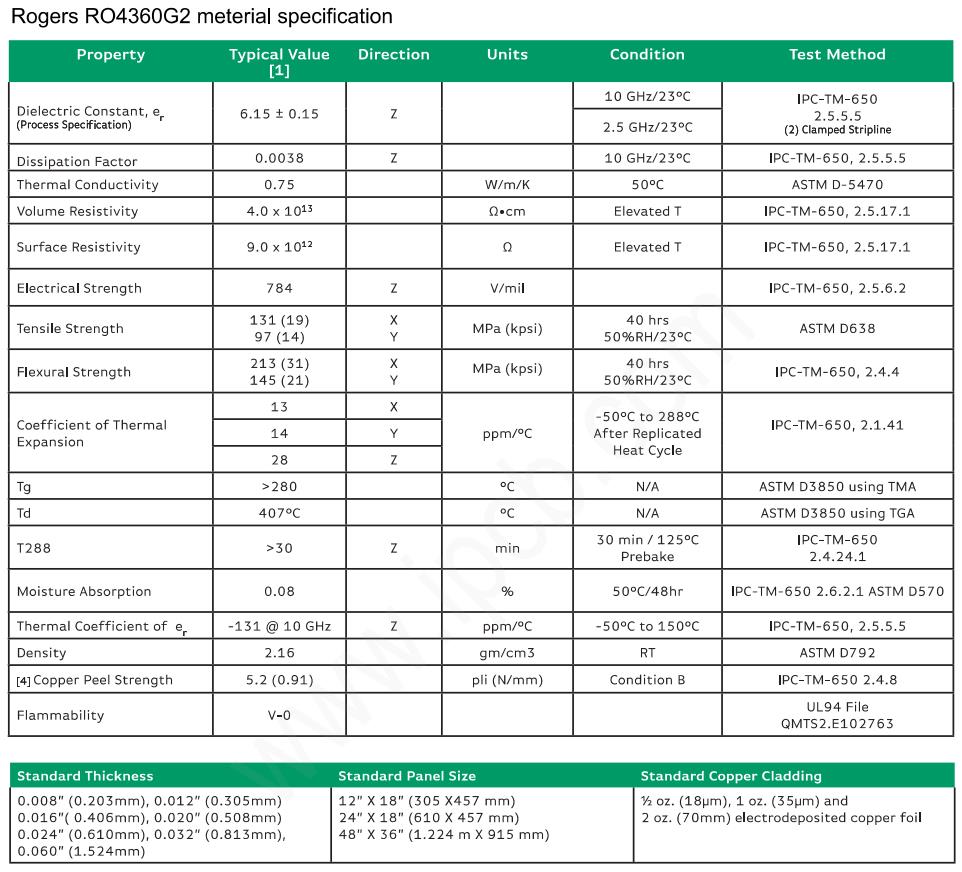

Main parameters of RO4360G2:

Dielectric constant (Dk): 6.15 ± 0.15

Dissipation factor: 0.0038 (10 GHz)

Thermal conductivity: 0.75 W/(m-K)

Z-axis thermal expansion coefficient: 28 ppm/°C

Glass transition temperature (Tg): > 280°C

From the electrical parameters of RO4360G2 and RF-60, the loss factor of RO4360G2 is higher than that of RF-60, but the thermal conductivity and thermal expansion coefficient are better than those of RF-60. RO4360G2 can adopt standard FR-4 processing technology, which can reduce the processing cost of PCB circuit boards. It is also suitable for RO4360G2 and FR-4 mixed pressure applications, and can be used for power amplifier mixed pressure RF boards with high PCB area requirements. RF-60 is a PTFE glass cloth material, which will have a dielectric constant step phenomenon at room temperature. RO4360G2 uses hydrocarbon resin material to avoid this phenomenon.

Rogers RO4360G2 is a high-performance PCB material designed for high-frequency applications. It has excellent electrical properties and thermal management capabilities, providing a reliable solution for demanding electronic designs. The core of RO4360G2 is composed of high-performance glass fiber reinforced hydrocarbon ceramic RF PCB material, which provides mechanical strength, dimensional stability and electrical insulation performance. Copper foil is bonded on both sides to form a conductive layer. Its characteristics include low dielectric loss and low signal loss, which are suitable for high-frequency transmission. Low loss tangent value ensures minimum signal attenuation and distortion. Stable electrical performance is consistent over a wide frequency and temperature range. Good mechanical strength and dimensional stability support precise manufacturing. High thermal conductivity contributes to efficient heat dissipation. In addition, the material is compatible with lead-free processes, meets environmental requirements, and performs well in multi-layer board construction. Typical application scenarios include cellular base station antennas and power amplifiers, RFID tags, automotive radars and sensors, and low noise block downconverters (LNBs) in satellite communications. These features make it an ideal choice for demanding applications in fields such as telecommunications, automotive, and satellite communications.

High-dielectric DK RF PCB material RO4360G2 has the advantages of high dielectric constant stability, strict control of batch consistency, and compatibility with FR-4 processing technology. It can replace Tyconic's RF-60 material in high dielectric constant PCB applications.