In the printed circuit board (PCB) industry, substrate materials play a crucial role. Rogers PCB fabrication refers to high-frequency circuit boards manufactured using materials exclusively supplied by Rogers. Rogers PCB fabrication exhibits excellent stability in terms of dielectric constant, hygroscopicity, and electrical and thermal properties. Rogers PCB fabrication laminates are primarily used in high-frequency microwave PCB fabrication. PCB prototypes made using Rogers PCB fabrication materials are collectively referred to as Rogers PCB fabrication.

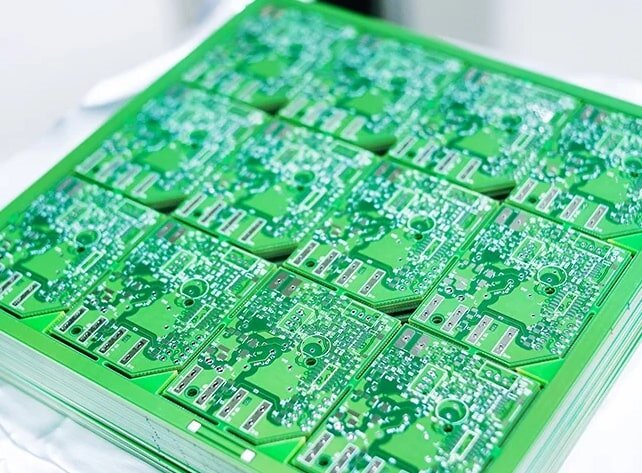

Rogers PCB fabrication

Main Rogers Material Series and Characteristics:

When selecting Rogers materials, different series offer different applicable frequency ranges, Dk/Df parameters, filler materials, and machining characteristics. Several typical series are listed below, along with their characteristics.

RO3000® Series: This series primarily uses PTFE (polytetrafluoroethylene) or ceramic-filled PTFE materials. It features a low Dk and very low Df, making it suitable for high-frequency, low-loss applications.

RO4000® Series: This is Rogers' most widely used series for mixed-signal, RF, and high-speed applications. Its dielectric constant (Dk) is typically around 3.3–3.5 (or higher), with a lower dielectric constant (Df), and it is relatively easier to process than pure PTFE. For example, RO4003C has a Dk≈3.38, suitable for applications from 1 GHz to 40 GHz.

RO5880: Based on polytetrafluoroethylene (PTFE), with a dielectric constant of 2.2, and a thickness range of 0.003 inches to 0.240 inches. Copper foil thicknesses are available in 0.5 oz, 1 oz, 2 oz, and 3 oz. This board features good dielectric constant stability, low loss, good impedance matching, and fast signal transmission speed. Simultaneously, the board exhibits excellent mechanical properties, including high strength, high rigidity, good heat resistance, and chemical corrosion resistance.

RT/duroid® Series: This series is geared towards UHF, microwave, and millimeter-wave applications, with lower dielectric constants (Dk) (e.g., ~2.2) for extremely low losses.

TMM® Series (Ceramic-Filled Thermosetting Materials): Suitable for applications requiring thermal management, power electronics, or high structural stability.

The dielectric constant of Rogers PCBs has a significant impact on board performance. Generally, a higher dielectric constant results in slower signal propagation and less noise interference. However, the dielectric constant also affects capacitance and signal reflection. Therefore, when designing a PCB, it is necessary to select appropriate materials based on the application scenario to achieve better circuit performance.

In general, the dielectric constant is a quantity that characterizes the degree to which a medium attenuates electromagnetic waves. A higher dielectric constant results in greater substrate loss and stronger electromagnetic wave attenuation.

The dielectric constant of Rogers PCBs reflects the relative ability of a dielectric to store electrostatic energy in an electric field. For dielectric materials, a smaller relative dielectric constant indicates better insulation.

Differences between FR-4 and Rogers materials:

In high-frequency, high-speed digital or RF/microwave designs, signals operate at extremely high frequencies (several GHz or higher) on a board as propagation lines. In this case, the dielectric constant and loss of the substrate have a significant impact on signal attenuation, reflection, crosstalk, and phase consistency. Rogers materials, due to their more stable dielectric constant (Dk) and lower dielectric constant (Df), result in less signal loss and more reliable transmission. In contrast, the Dk of FR-4 can vary considerably under different frequencies, temperatures, and humidity levels, leading to more significant losses.

1. FR-4 materials are generally less expensive than Rogers materials.

2. Rogers materials perform better at high frequencies compared to FR-4.

3. FR-4 materials have a higher dissipation factor (Df) than Rogers materials, resulting in increased signal loss.

4. Regarding impedance stability, Rogers materials offer a wider range of Dk values compared to FR-4.

5. Regarding dielectric constant, FR-4 has a dielectric constant (Dk) of approximately 4.5, lower than Rogers materials, which range from approximately 6.15 to 11.

6. In terms of temperature management, Rogers materials exhibit less variation compared to FR-4.

FR4 PCB

In summary, it is crucial to assess the "real" need for Rogers materials early in the design process: FR-4 may be sufficient if the frequency is low, cost is a concern, and performance requirements are moderate; however, Rogers boards become the ideal choice when frequency, loss, reliability, thermal management, and mechanical stress all reach a certain level.

Rogers PCB Fabrication Applications

Rogers PCBs are frequently used in applications requiring high-frequency performance, excellent signal integrity, and high thermal stability. Some common applications of Rogers PCBs are listed below.

RF and Microwave Circuits: Rogers PCBs are widely used in devices with high RF and microwave signal usage, such as mobile base stations, radar systems, and satellite communications.

High-Speed Digital Circuits: Rogers PCB boards consistently support high-speed data transmission while minimizing signal loss.

Aerospace and Military Applications: Rogers laminates are used here because they provide PCBs with durability and thermal stability. Signal integrity is also critical for PCBs, as they must operate in the harsh environments of military and aerospace applications.

iPCB is a Rogers PCB fabrication manufacturer serving industries such as telecommunications, aerospace, and advanced computing. Leveraging our expertise in Rogers PCB fabrication, we are able to provide customized solutions to meet your specific performance needs.