When the frequency of digital logic circuits touches or exceeds the range of 45 MHZ to 50 MHZ and circuits operating in this high frequency band account for a significant percentage (e.g., one-third) of the overall electronic system, such circuits are usually defined as high-frequency circuits.The design of high-frequency circuits is extremely challenging and its complexity is particularly significant, where the precision of the high frequency pcb layout plays a crucial role in the overall design process.

While a good schematic does not guarantee good wiring, good wiring starts with a good schematic.When drawing a schematic diagram, you need to consider the signal flow of the entire circuit. If there is normal and stable signal flow from left to right in the schematic, then there should be equally good signal flow on the PCB circuit board. Provide as much useful information as possible on the schematic diagram. Because sometimes circuit design engineers are unavailable, customers will ask us to help solve circuit problems, and the designers, technicians, and engineers doing the work would be grateful.

In addition to the common reference designations, power consumption and fault tolerance, what other information should be given in the schematic? Here are some suggestions for turning an average schematic into a first-class schematic. Add waveforms, shell mechanical information, printed line length, and blank areas; indicate which components need to be placed on the PCB;give adjustment information, component value ranges, heat dissipation information, controlled impedance printed lines, precautions, and brief circuit action instructions ( and others).

If you are not designing the wiring yourself, make sure you have enough time to scrutinize the wiring crew's design. Prevention is better than cure at this point. Don't expect the wiring crew to understand your ideas. Your advice and guidance is paramount in the early stages of wiring design. The more information you provide and the more people involved in the entire wiring process, the better the PCB will be.Set a tentative completion point for the high frequency pcb layout design engineer a quick check against your desired cabling progress report. This “closed loop” approach prevents cabling from going astray and minimizes the potential for rework.

Instructions to the layout engineer include: a brief description of the circuit function,a PCB sketch indicating the location of the inputs and outputs, PCB stackup information (e.g., the thickness of the board, how many layers there are, and details about each signal layer) and the ground plane—the functional (consumption, ground, analog signals, digital signals, and RF signals); which signals are required on each layer; where important components are needed; and; the exact location of bypass components; which printed circuits are important; which circuits require controlled impedance printed circuits; Which rows need to match length; the size of the components; which printed lines need to be far away (or close); which lines need to be far away (or close to each other); which components need to be on top of the high frequency pcb and which should be on the bottom.

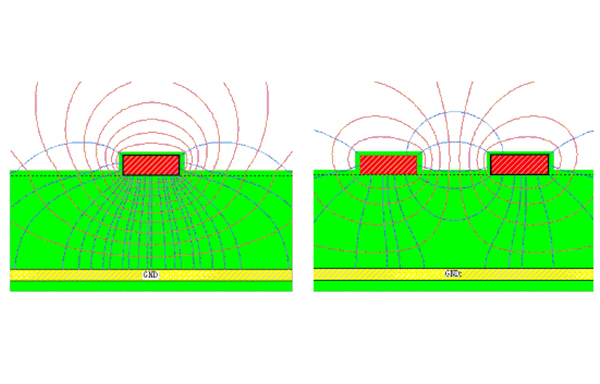

Bypassing an amplifier's power supply to reduce noise is an important aspect of PCB design, including high-speed op amps or other high-speed circuits. There are two common configuration methods for bypassing high-speed op amps

Power supply ground: This method is most effective in most cases, using multiple parallel capacitors to connect the op amp's power supply pin directly to ground. Generally speaking, two capacitors in parallel are sufficient - but adding a parallel capacitor may be beneficial in some circuits.

Paralleling capacitors with different capacitance values helps ensure that the power pins see only low AC impedance over a wide frequency band. This is especially important at the op amp's PSR attenuation frequency.The capacitor helps compensate for the amplifier's reduced PSR.Maintaining a low-impedance path to ground over many octaves will help ensure that unwanted noise does not enter the op amp. Figure 1 shows the advantages of using multiple capacitors in parallel.At low frequencies,the large capacitor provides a low-impedance path to ground. But once the frequency reaches its own resonant frequency,the capacitance of the capacitor will weaken and gradually become inductive.This is why it's important to use multiple capacitors: when the frequency response of one capacitor starts to drop.

Start directly with the op amp's power pins; the capacitor with the smallest capacitance and smallest physical size should be placed on the same side of the PCB as the op amp - and as close to the amplifier as possible. The ground terminal of the capacitor should be connected directly to the ground plane using the shortest possible pin or printed wire. The above ground wire should be as close as possible to the load terminal of the amplifier to reduce interference between the power supply and the ground terminal. Figure 2 shows this connection method.