What is high quality PCB?

1.PCB size and thickness must be consistent with the specified external size and thickness, no deviation. The surface of the circuit board is free of defects, deformation, peeling,scratches,circuit breaks, short circuits, oxidized white, yellow, unclean or excessive etching traces, and free of dirt, copper particles and other impurities.

2.The ink covering layer is even and bright, without peeling, scratches, exposed copper, deviation, printing plate and other phenomena.

3.Silk screen printing symbols and letters are clear, without omission, inversion, deviation and other undesirable phenomena.

4.The carbon film shall not have defects, deviations, short circuits, circuit breakers, printing reverse and other phenomena.

5.PCB substrate molding, no leakage, deviation, collapse holes,Phi Fong,plug holes, burst beer, beer reverse, compression and other phenomena.

6.PCB edges are smooth, if the V-cutting process, pay attention to the V-cutting groove is caused by broken lines, whether the two sides are symmetrical.

7.The requirements of the components installed after the use of good, that is, the power connection to meet the requirements.

8.The line width, line thickness, line spacing in line with the requirements to avoid line heating, open circuit, short circuit.

9.Copper skin is not easy to fall off under high temperature.

10.The copper surface is not easy to oxidize, affecting the device running speed, oxidation will soon be bad.

11.No additional electromagnetic radiation.

12.The shape is not deformed, to avoid the device after the shell deformation and screw holes misalignment.Now are mechanized devices, circuit board holes Bit and circuit and the plane of the deformation error should be within the allowable range.

13.High temperature, high humidity and special environmental resistance is also under consideration.

14.The surface mechanical properties should meet the equipment requirements.

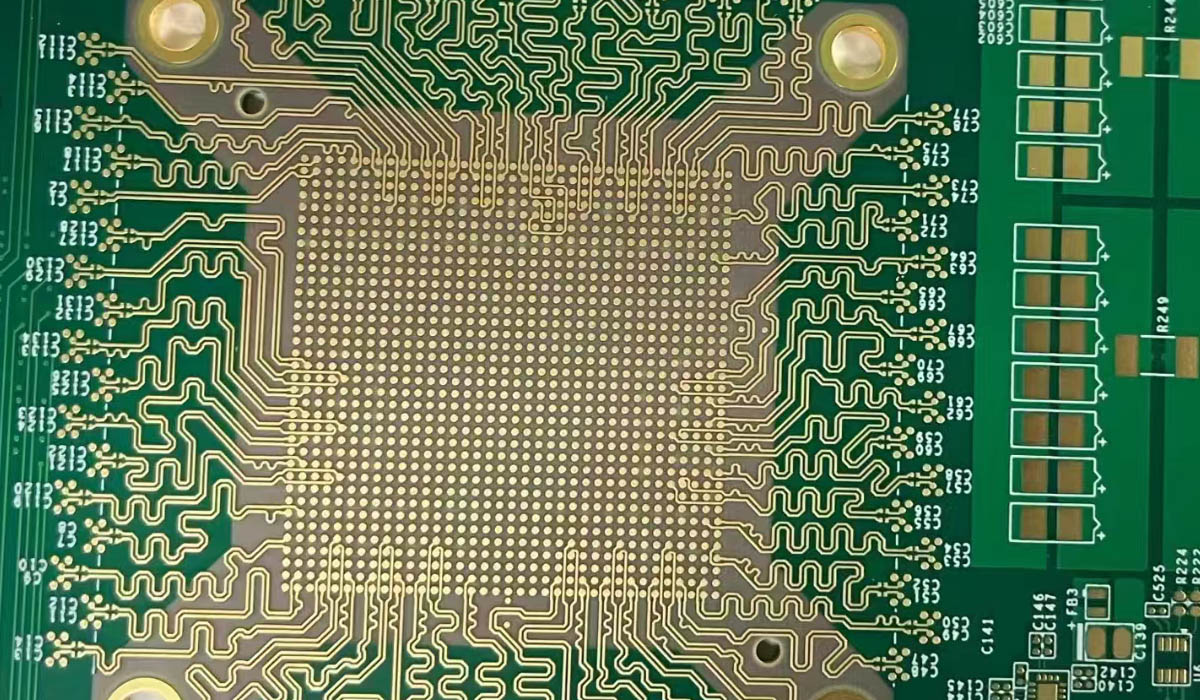

High Quality PCB

How to do high quality PCB design?

1.PCB component layout

Reasonable pcb component layout is the basic premise of the design of high-quality circuit diagrams. Requirements on component layout are mainly installation, force, heat, signal, aesthetics of the six requirements.

2.PCB Installation

Refers to the specific application of the scene, in order to install the circuit board into the chassis, enclosure, slot, without space interference, short circuit and other accidents, and so that the specified connection plug-in program is located in the chassis or enclosure of the specified location and a series of basic requirements. We will not go into details here.

3.PCB stress

The circuit board should be able to withstand installation and work in a variety of external forces and vibration. In order to do this, the circuit board should have a reasonable shape, a variety of holes on the board (screw holes, shaped holes) should be reasonably arranged. General holes and board edge distance should be at least greater than the diameter of the holes. At the same time, it should also be noted that shaped holes caused by the weakest cross-section of the board should also have sufficient bending strength. Board directly “out” of the equipment housing connected to the external hook-up program, in particular, should be reasonably fixed to ensure the reliability of long-term use.

4.PCB heat

For high-power,serious heat devices, in addition to ensuring that the conditions of heat dissipation, but also pay attention to be placed in the appropriate location. Especially in the precision analog system, to pay extra attention to the temperature field generated by these devices on the fragile preamplifier circuit of the adverse effects. General power is very large part should be made into a separate module, and with the signal processing circuit to take certain thermal isolation measures.

5.PCB signal

Signal interference PCB layout design of the most important factors to consider. Several of the most basic aspects are: weak signal circuit and strong signal circuit is separated or even isolated. AC part and DC part of the separation. Separate the high-frequency section from the low-frequency section. Pay attention to the direction of the signal lines. Layout of ground wires. Appropriate masking, filtering and other measures. These are a large number of thesis repeatedly emphasized, and will not be repeated here.

6.PCB aesthetics

Not only to consider the components placed in a neat and orderly, but also to consider the beauty of the smooth alignment. As the general layman sometimes emphasize the former, as a one-sided assessment of the merits of the circuit design, for the image of the product, in the performance requirements are not demanding to prioritize the former. However, in high-performance occasions, if you have to use dual-panel, and the PCB is also encapsulated inside, usually invisible, should give priority to emphasize the aesthetics of the alignment.

7.PCB layout aesthetics

Avoid right angles when making turns, and try to use diagonal lines or arcs for transitions. Alignment should be neat and orderly, and centrally arranged in separate categories, not only to avoid mutual interference of signals of different nature, but also to facilitate inspection and modification. For digital systems, the same camp of signal lines do not have to worry about interference between the problem, but similar to read, write, clock, such as control signals, it should be alone, the best use of wires to protect up.

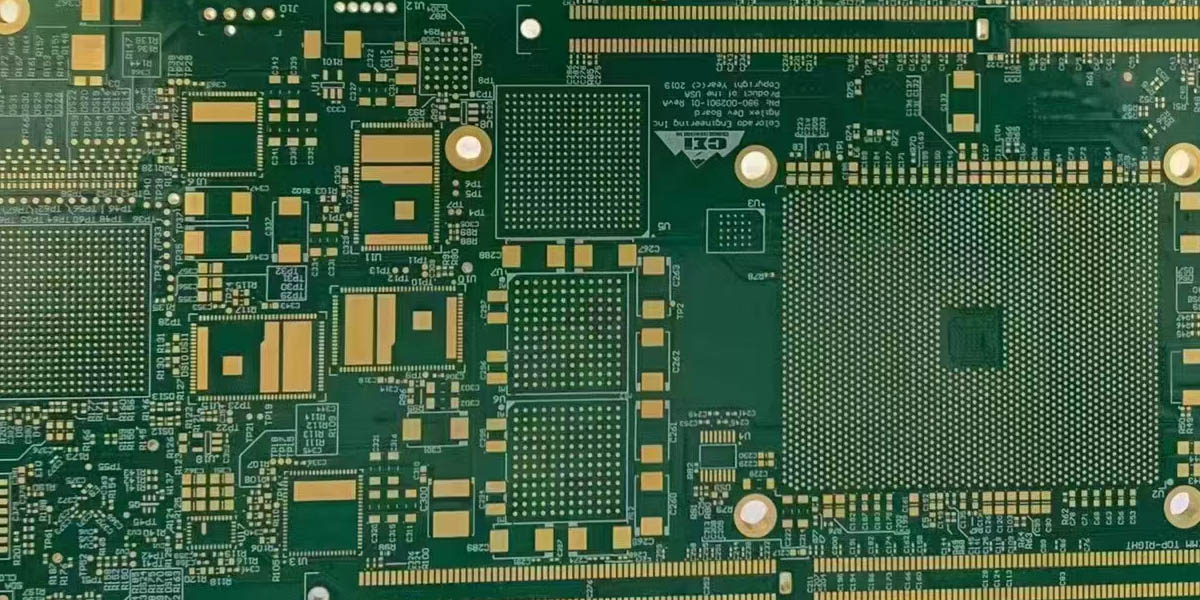

High Quality PCB

Above are the features of high quality PCB design and high quality PCB that we have shared.