A multilayer PCBs mean pcb with two or more layers. It consists of connecting conductors and pads for mounting and soldering electronic components on several layers of an insulating substrate. This provides both electrical connectivity and insulation between the layers. A multilayer circuit board is one with multiple copper layers.

Multilayer PCBs offer a compact component layout, reducing manufacturing costs. Consumer electronics and cost-effective products typically utilize multilayer PCBs. Multilayer boards are the preferred choice for many mid- to high-end applications due to their moderate layer count, high design flexibility, and cost-effectiveness.

How are multilayer PCBs manufactured? The following explains the manufacturing process.

A PCB core consists of a base material layer and two copper layers. It is cut from double-sided copper-clad laminate. Between the copper layers and the PCB core is prepreg. The prepreg and PCB base are made of the same material, but the prepreg is pre-cured while the base is cured. An outer PCB layer is formed by riveting the prepreg to the copper foil.

Multilayers include signal layers, ground (GND) layers, and power layers. The top and bottom layers must be signal layers. Multiple internal PCB layers include signal, ground, and power layers.

Multilayer PCBs are multilayer circuit boards used in electrical products. Multilayer boards utilize more single- or double-sided boards. PCBs with one double-sided inner layer and two single-sided outer layers, or two double-sided inner layers and two single-sided outer layers, alternately joined together using a positioning system and insulating adhesive, with conductive patterns interconnected as designed, become four- or six-layer printed circuit boards, also known as multilayer printed circuit boards.

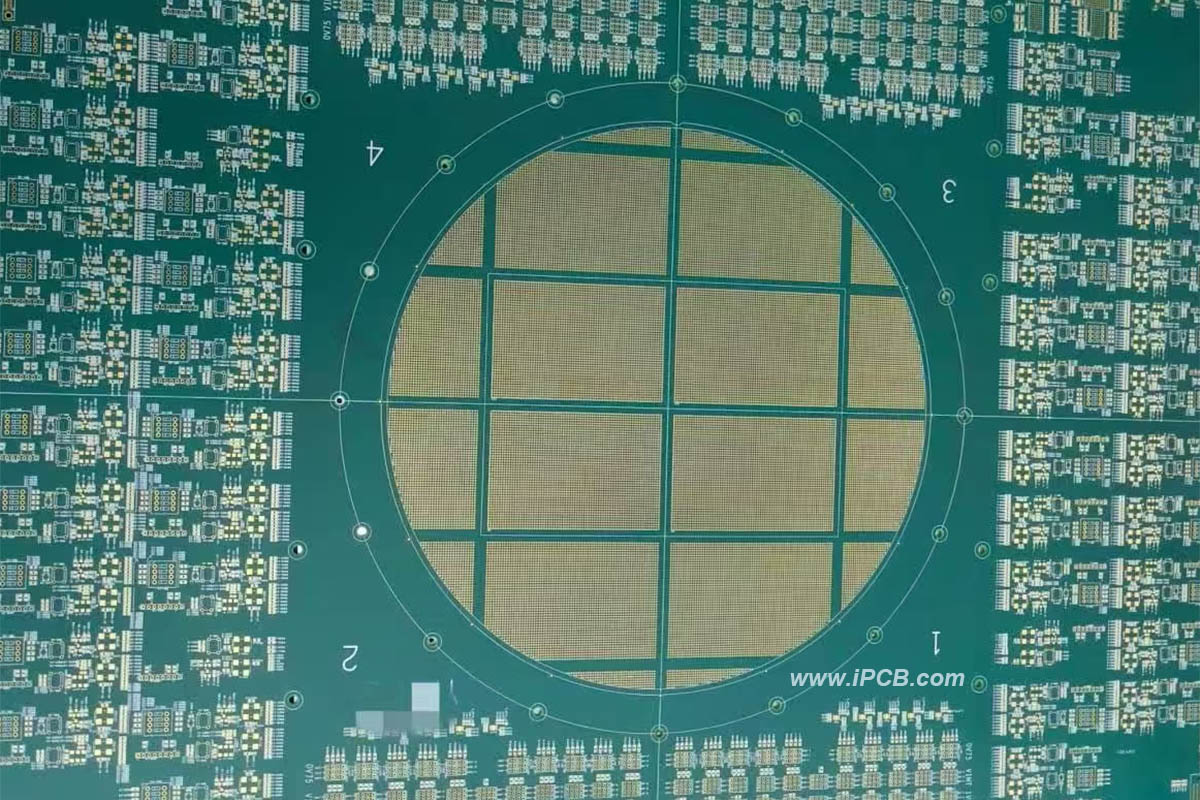

multilayer PCBs

The continuous development of SMT (surface mount technology) and the introduction of new generations of SMDs (surface mount devices), such as QFP, QFN, CSP, and BGA (particularly MBGA), have made electronic products more intelligent and miniaturized, driving significant reforms and advancements in PCB industry technology. Since IBM successfully developed high-density multilayer boards (SLC) in 1991, major companies worldwide have also developed various high-density interconnect (HDI) microvia boards. The rapid advancement of these processing technologies has driven PCB design towards multi-layer, high-density wiring. Multilayer PCBs, with their flexible design, stable and reliable electrical performance, and superior economical performance, are now widely used in the production and manufacturing of electronic products.

Manufacturing a 6-layer PCB

A 6-layer PCB is manufactured by laminating PCB layers onto a PCB core. Once the circuit is etched onto the PCB core and the third and fourth layers are completed, the second and fifth layers are laminated onto the core under high temperature and high pressure. The circuit is then etched onto the second and fifth layers. The top and bottom layers are also attached to the 4-layer board and etched with circuits. Solder mask is applied to the top and bottom layers, and surface treatment is performed on the PCB pads.

Two circuit etching methods can be used for PCB layers. The choice depends on whether HDI (High Density Interface) (HDI) vias are required for that layer.

Front-side etching uses an alkaline solution as the etching solution. This method is used for PCB layers that do not require HDI vias. During the process, ultraviolet light projects the circuit pattern onto a copper layer that has been printed with a UV-sensitive film. The film on the copper in the shadow of the circuit pattern remains liquid, while the film on the unwanted copper hardens. The liquid film is then washed off. Tin is then plated on the exposed copper as a protective layer. Next, the dry film is stripped off. Finally, the exposed unwanted copper is etched away with an alkaline solution, leaving only the copper in the circuit pattern.

Negative planar etching uses an acid etchant. This method is used for PCB layers that require HDI holes. The process involves UV light casting the shadow of the circuit pattern onto a copper layer printed with another UV-sensitive film. The film on the copper in the shadow of the circuit pattern hardens, while the film on the unwanted copper remains liquid. The liquid film is then washed off. The exposed unwanted copper is etched away with acid. Finally, the dry film is stripped off, leaving only the copper in the circuit pattern.

Both circuit etching methods can be used for the core PCB; for the top and bottom layers, only positive planar etching can be used.

If a 6-layer PCB only has PTH holes, the PCB is mechanically drilled after lamination, and copper is then electroplated over the PTH holes for circuit layer connections. For 6-layer HDI PCBs, the top, bottom, second, and fifth layers are laser drilled and plated before lamination. The PCB core is also plated by laser drilling and electroplating before lamination.

Multilayer PCB Manufacturer - iPCB

iPCB is a reliable multilayer PCB manufacturer. We can manufacture and assemble high-end PCBs with 1 to 110 layers, so multilayer PCB fabrication is also available to order.

Here are some reasons to partner with iPCB:

1. Our multilayer PCB manufacturing capabilities meet HDI requirements, as well as high-speed or high-frequency circuit design needs.

2. We have extensive experience manufacturing multilayer PCBs, such as multilayer FR4 PCBs, multilayer Teflon-based PCBs, multilayer flexible PCBs, and multilayer rigid-flex PCBs.

3. We provide free and professional one-on-one design/engineering support for your multilayer PCB project.

4. We provide free Design for Manufacturing (DFM), Design for Technical Specifications (DFT), and Design for Flex (DFX) for multilayer PCB fabrication and assembly, with no minimum order requirements.

Multilayer PCB manufacturing is generally outsourced, so when providing drawings, they must be accurate and clearly documented. Details such as material selection, lamination sequence, board thickness, tolerance requirements, and processing techniques should be clearly stated. When exporting PCB Gerber data, it's recommended to use the RS274X format. This format offers the following advantages: CAM systems can automatically input data, eliminating manual intervention and reducing hassles. It also maintains high consistency and minimizes errors.

If you require multilayer PCB manufacturing or assembly, or have any questions about multilayer PCB design or manufacturing, please feel free to email us your Gerber files and information.