As more customers opt for one-stop services when manufacturing PCBA, covering PCB production, PCBA assembly, and program burning and testing, many are curious about how the program burning process works. Let's explore how programs are burned onto PCBA.

What is PCBA Program Burning?

To enable a PCBA (Printed Circuit Board Assembly) to perform its intended function, the chip on the PCBA must operate correctly. Burning a program into the chip allows it to run. PCBA program burning refers to the process of transferring the written program into the internal memory of the chip, which can be done either offline or online.

With the widespread use of chips like eMMC, the trend is toward smaller and flatter packaging, such as BGA (Ball Grid Array) and QFN (Quad Flat No-lead). However, adapters for these packaging types can be expensive.

Offline PCBA Program Burning

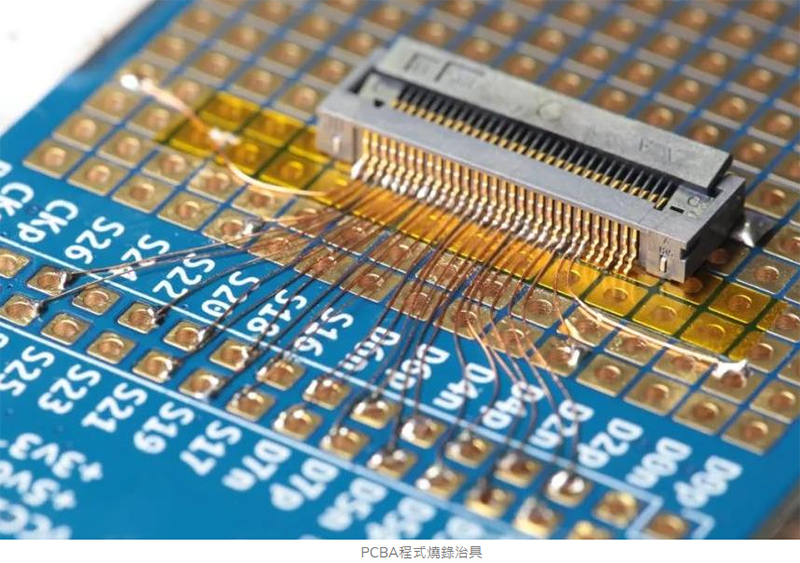

Offline burning involves connecting the chip to an adapter, which then pairs with the chip to facilitate program burning. Essentially, the adapter acts as a precise fixture, and each chip packaging type requires a matching adapter for the process. If errors arise during production testing, the chip must be removed from the adapter and reburned following the appropriate procedure, resulting in higher labor and material costs.

Unexpected issues may occur during PCBA production, such as the circuit board insufficient heat resistance, which can deform the chip during removal, adding the risk of increased scrap.

Online PCBA Program Burning

Online burning uses standard chip communication buses such as USB, SWD, JTAG, and UART, with fixed interfaces and fewer pins to connect during burning. Since the communication speed is not high, ordinary cables can complete the task without significant resource consumption.

If errors are discovered during production testing, the program can be reburned without removing the chip, reducing costs and increasing efficiency.

Moreover, as production lines move towards automation, manufacturers increasingly integrate ICT (In-Circuit Test) and FCT (Functional Circuit Test) into production. By combining automatic fixtures with online burning, manual operations can be eliminated, allowing for the burning process to take place immediately after the board is mounted, followed by automated testing. This full automation significantly enhances production efficiency.

PCBA program burning involves multiple capabilities, such as:

Open circuit (open), short circuit (short) detection, component errors, missing components, tombstoning, bridging, and polarity issues.

Measurement of resistors, capacitors, inductors, transistors, diodes, voltage regulators, triodes, optocouplers, relays, FETs, ICs, connectors, etc.

Using TestJet to measure connectors and IC components with open/short pins without probe points.

DC/AC voltage and frequency measurement.

Electrical function tests and the execution of low-level programs for self-diagnostics.

Active component testing via Boundary-scan/JTAG.

Automatic downloading of software or operating systems into the board’s memory.

Quality Control in PCBA Program Burning

The quality control department organizes reviews for non-conforming items or departments responsible for defects and forms problem-solving teams.

Potential defects or non-conforming items are analyzed using tools like tests, simulations, data analysis, and QC methods, and preventive measures are designed to control quality.

For existing defects, the problem-solving team reassesses and revises related technology, standards, or design levels, ensuring that similar issues in all products or processes are prevented.

Choosing the right burning method and implementing stringent quality control measures are crucial to ensuring the success of the PCBA program burning process.