When designing high-performance electronic devices, choosing the right material is critical. Among the various available options, aluminum oxide (Al₂O₃) is an excellent choice for ceramic printed circuit boards (PCBs) due to its excellent thermoelectric properties. However, not all alumina is created equal! In ceramic PCB manufacturing, alumina (Al₂O₃) is used as a substrate material, and then the question may be encountered: how to choose between 96% and 99% alumina?

What is aluminum oxide? Why is it used in ceramic PCBs?

Alumina ceramic substrates are mainly composed of a white amorphous powder commonly known as alumina or simply Al₂O₃. It has a density of 3.9-4.0 g/cm3, a melting point of 2050°C, and a boiling point of 2980°C. Alumina is not soluble in water. Alumina is insoluble in water and exhibits excellent properties in a variety of applications.

Common alumina ceramics are classified according to their Al₂O₃ content and include 99%, 95%, 90%, 96%, 85%, and sometimes 80% or 75% alumina variants. 99% alumina is alumina that is 99.5% or 99.8% pure. It is white or ivory in color and has excellent properties such as high wear resistance, resistance to acid and alkali corrosion, and excellent performance at high temperatures (1600-1700 degrees Celsius). In addition, it exhibits good chemical stability, high electrical insulation, strong adsorption capacity and wear resistance. As a result, it is widely used in a variety of applications, including lamps, electronics, sandblasting nozzles, automotive parts and wear-resistant components.

On the other hand, 96% alumina is slightly less pure than 99% alumina, but still offers economic benefits while providing good thermal conductivity and insulating properties.

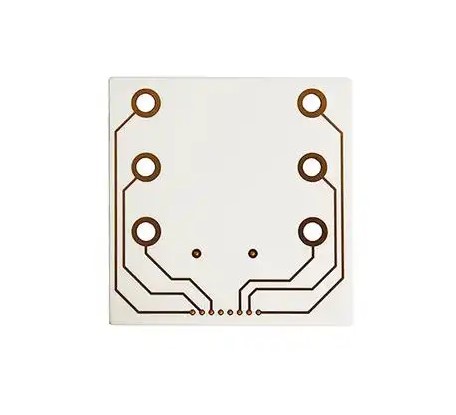

Ceramic PCB

96% Alumina

As the name implies, 96% alumina is composed of 96% pure alumina and 4% other trace elements. Due to its balanced performance and cost-effectiveness, this type is widely used in various electronic applications. Here are some of its typical properties.

Thermal conductivity: Good thermal conductivity effectively dissipates heat from high power components.

Dielectric strength: Satisfactory dielectric strength ensures reliable insulation between conductive wires on the PCB.

Mechanical Strength: Its robust nature contributes to the overall mechanical integrity of the ceramic PCB.

Economy: 96% alumina is more cost-effective than its higher purity counterparts, making it an attractive choice for cost-sensitive projects.

99% Alumina

Compared to 96% alumina, 99% alumina is a premium variant with an impressive 99% purity level accompanied by minimal impurities. It is suitable for use in the most demanding scenarios where superior mechanical, electrical, thermal or corrosion resistance properties are required. Here are the main advantages of 99% aluminum oxide.

Uniform heating and rapid heat dissipation: Thanks to its superior thermal conductivity compared to 96% alumina, 99% alumina ensures uniform heating of the material as a whole and contributes to efficient heat dissipation. This characteristic is particularly important for equipment that generates a lot of heat during operation.

Simple and compact: The inherent properties of the material allow for simple and compact designs, resulting in smaller equipment. This advantage is especially critical for space-constrained applications.

Flat and smooth surface for high strength: 99% alumina has a flat and smooth surface, which increases its mechanical strength. This ensures that the material remains strong and is not easily damaged during use.

Resistance to acid and alkali corrosion, durability: Due to its high purity, 99% alumina exhibits excellent resistance to acid and alkali corrosion, ensuring the material's longevity and durability in corrosive environments.

Precision and Accuracy: The higher purity of 99% alumina results in better precision and stability in a variety of electrical properties. This characteristic is especially beneficial for high-precision electronic applications that require consistent and reliable performance.

In general, alumina is chosen for substrates because of its good thermal conductivity, high electrical resistance, high hardness, high electrical insulation, and high corrosion resistance, making it one of the most commonly used ceramic PCBs on the market. For 96% and 99% concentration, how to choose?

1, 96% concentration of aluminum oxide

Cost-effective: Compared to 99% alumina, 96% alumina costs less and is suitable for more cost-sensitive projects.

Balanced performance: In most electronic components with low to medium power requirements, 96% alumina provides stable and cost-effective performance.

Ease of processing: Easier to process than 99% alumina, suitable for cutting, drilling and other treatments, and convenient for preparing substrates of various shapes.

Application areas: Suitable for low power electronic components, sensors, capacitors, miniature relays, microwave components, etc.

2、99% Concentration aluminum oxide

High purity: with 99% or higher purity, it brings higher chemical purity and density, and is suitable for scenarios with very high performance requirements.

Excellent performance: with better thermal conductivity to ensure that the material as a whole is uniformly heated, helping to dissipate heat efficiently. Suitable for high-power LEDs, high-voltage integrated circuits, high-temperature sensors, high-frequency electronic components, etc.

Mechanical Strength: High hardness and mechanical strength, it can withstand greater force and pressure, ensuring that the material remains strong in complex environments.

Corrosion resistance: Due to its high purity, it exhibits excellent resistance to acid and alkali corrosion, ensuring the longevity and durability of the material in corrosive environments.

High precision: better precision and stability in various electrical properties characteristics, suitable for high-precision electronic applications requiring consistent reliable performance.

3、How to choose aluminum oxide?

Project requirements: first of all, clarify the specific requirements of the project on power, voltage, temperature, high power, high voltage, high temperature environment, 99% alumina is a better choice.

Cost considerations: according to the project budget, weigh the material cost and performance requirements, if you want to consider the cost, 96% alumina is better.

Application Scenario: For high thermal conductivity, high corrosion resistance and high mechanical strength, 99% alumina is preferred.

Multi-functional design: If the device has multiple functional areas, consider using 99% alumina in the high-performance area and 96% alumina in the area with lower performance requirements, so as to achieve a balance between cost and performance.

Choosing the right aluminum oxide material for your ceramic PCB depends on a number of factors, including project requirements, budgetary constraints and equipment design.