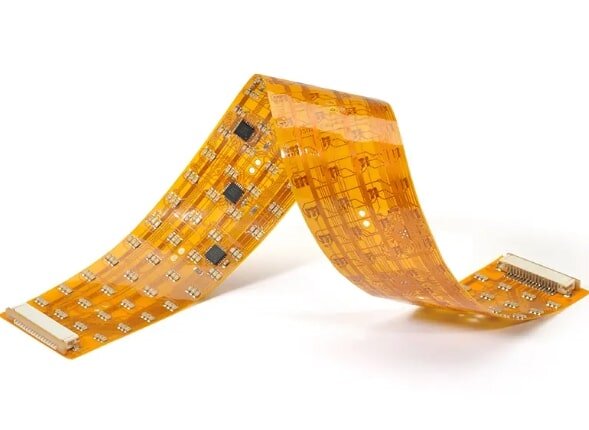

FPC flexible circuit boards are characterized by being thin, light, short and small, so they are prone to dents, folds, and scratches during use. They have low mechanical strength and are prone to cracking.The purpose of FPC reinforcement (stiffener) is to strengthen the mechanical strength of FPC and facilitate surface mounting of parts. There are many types of reinforcement films, depending on the use requirements of the product, mainly PET, PI, adhesive backing, metal or resin reinforcement plates, etc.

FPC reinforcement

Why is it necessary to add FPC reinforcement?

A pure flexible FPC PCB can withstand fewer components than a rigid-flexible PCB. The rigid part of the rigid-flexible combination can also be as complex as a traditional rigid circuit board. FPC reinforcement is occasionally laminated with the cover layer at the same time.

FPC (flexible circuit board) has been widely used in modern electronic products due to its thin, light, short and bendable characteristics. However, due to its low mechanical strength, it is easy to produce creases, scars and other problems during use. Therefore, the FPC reinforcement process came into being to increase the thickness and rigidity of specific areas to improve the durability and stability of FPC.

When is it recommended to add FPC reinforcement?

1. Components are close to or in active or dynamic bending zones

2. The size and weight of components put pressure on the flexible zone

3. A large number of SMT pads make planarity critical

4. Connectors that need to be repeatedly inserted or assembled need a reinforcement or help relieve stress on the pads.

Situations where adding FPC reinforcement is not recommended?

1. Small static components do not put a lot of pressure on the flexibility of the PCB.

How to choose FPC reinforcement?

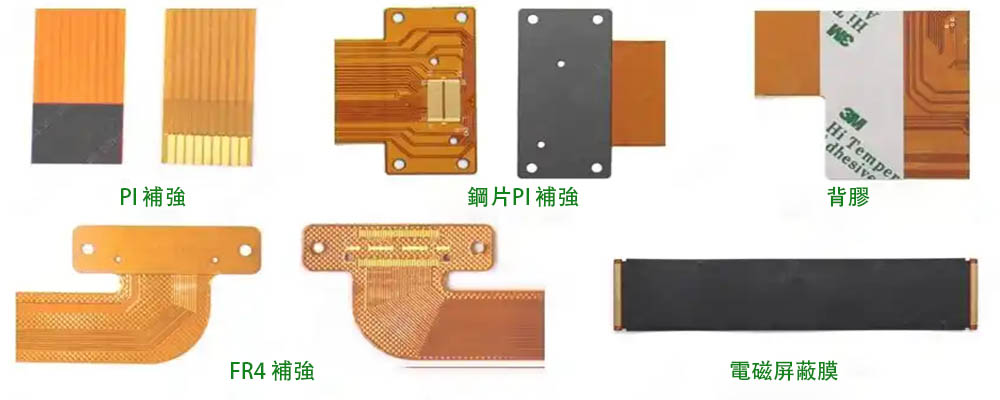

Reinforcements usually have FR4, PI (Kapton), stainless steel and aluminum reinforcements. So how do we choose the right FPC reinforcement? Here are six commonly used FPC reinforcements:

1. PI FPC reinforcement, PI is usually used when the end of the flexible FPC must be thickened and inserted into the ZIF connector. However, using Kapton (PI) requires a separate lamination cycle. For the plug area, we will need to add PI reinforcement to meet the total thickness of 0.2mm, 0.3mm or 0.5mm.

PI is a high-performance engineering plastic with excellent heat resistance, mechanical strength and electrical insulation properties. It is widely used in aerospace, microelectronics and other fields. The tolerance of PI reinforcement can be controlled at +/-0.03mm, with high precision and high temperature resistance (130℃ -280℃), and it is one of the commonly used materials in FPC reinforcement. For example, in the camera module of a smartphone, the FPC needs to be bent and stretched frequently. The use of PI reinforcement can effectively prevent the FPC from creases and breaks during use, and improve the stability and service life of the camera.

FPC reinforcement

2. FR4 FPC reinforcement, FR4 reinforcement can be completed in the same lamination cycle. FR4 reinforcement is usually added to the USB connector area.

FR4 reinforcement: FR4 is mainly composed of glass fiber cloth and epoxy resin glue, with good mechanical properties, dimensional stability and impact resistance. If the thickness is less than 0.1mm, the tolerance can be controlled at +/-0.05mm; if the thickness is greater than 1.0mm, the tolerance is +/-0.1mm. FR4 reinforcement is often used in applications that require additional rigidity and strength. For example, in the touch screen connection part of the tablet computer, since it needs to withstand greater pressure and friction, the use of FR4 reinforcement can significantly improve the durability and reliability of the FPC.

3. Stainless steel FPC reinforcement, stainless steel reinforcement is not easy to deform. It has good hardness. It can play the role of heat dissipation, conductivity and induction.

Steel sheet reinforcement: Steel sheet reinforcement mainly refers to 303 stainless steel reinforcement, which has high mechanical strength and support strength, but requires manual assembly, the process is complicated and the cost is high. Steel sheet reinforcement is usually used for specific industrial and military applications. For example, in industrial robots, some key parts of the FPC need to withstand greater mechanical loads, and the use of steel sheet reinforcement can ensure the stability and safety of the FPC in harsh environments.

4. Aluminum FPC reinforcement, aluminum reinforcement has the best heat dissipation effect, because it usually requires a mold to stamp the shape of the aluminum reinforcement, and then the cost is the highest.

5. Epoxy resin reinforcement: Epoxy resin is usually used as the bonding layer material of the reinforcement plate, and can also be used to make the reinforcement plate itself. It has good mechanical properties and chemical resistance, but its thermal performance is relatively low. In some medical devices, FPC needs to have good biocompatibility and chemical corrosion resistance, and epoxy resin reinforcement can meet these special requirements.

6. Polyester (PET) reinforcement: PET material has low cost and good mechanical strength and chemical resistance. Although its heat resistance is not as good as polyimide, polyester is still a commonly used reinforcement material in applications where temperature requirements are not high. For example, in wearable devices such as smart bracelets, the use environment of FPC is relatively mild. Using PET reinforcement can reduce costs while ensuring product performance.

iPCB has extensive expertise in manufacturing and assembling rigid PCBs, flexible PCBs, and rigid-flexible PCBs. If you need printed circuit board manufacturing or assembly, please contact our PCB experts and we will be happy to help you.

FPC reinforcement design considerations

Reinforcement size: FPC reinforcement usually needs to be 1mm larger than the single side of the pad to prevent creases on the edge of the pad when bending, resulting in open circuits.

Material selection: The selection of appropriate reinforcement materials should be determined according to the specific application requirements, working environment and mechanical performance requirements of FPC.

Pressing parameters: Correctly adjusting the pressing parameters and controlling the pressing time are crucial to improving the quality of FPC

The FPC reinforcement process plays an important role in improving the durability and stability of flexible FPC circuit boards. By selecting appropriate FPC reinforcement materials and process flows, the mechanical strength of FPC can be effectively enhanced to meet various complex application requirements.