Choosing the right PCB (printed circuit board) material plays a decisive role in the performance, reliability, and cost control of the circuit board. Given the characteristics of different PCB materials, they are each suitable for specific application scenarios.

Standard FR-4 (glass fiber epoxy resin)

Features: FR-4 material is known for its good insulation, mechanical strength, and heat resistance.

Applicable: Suitable for most conventional electronic devices and occasions with certain cost requirements.

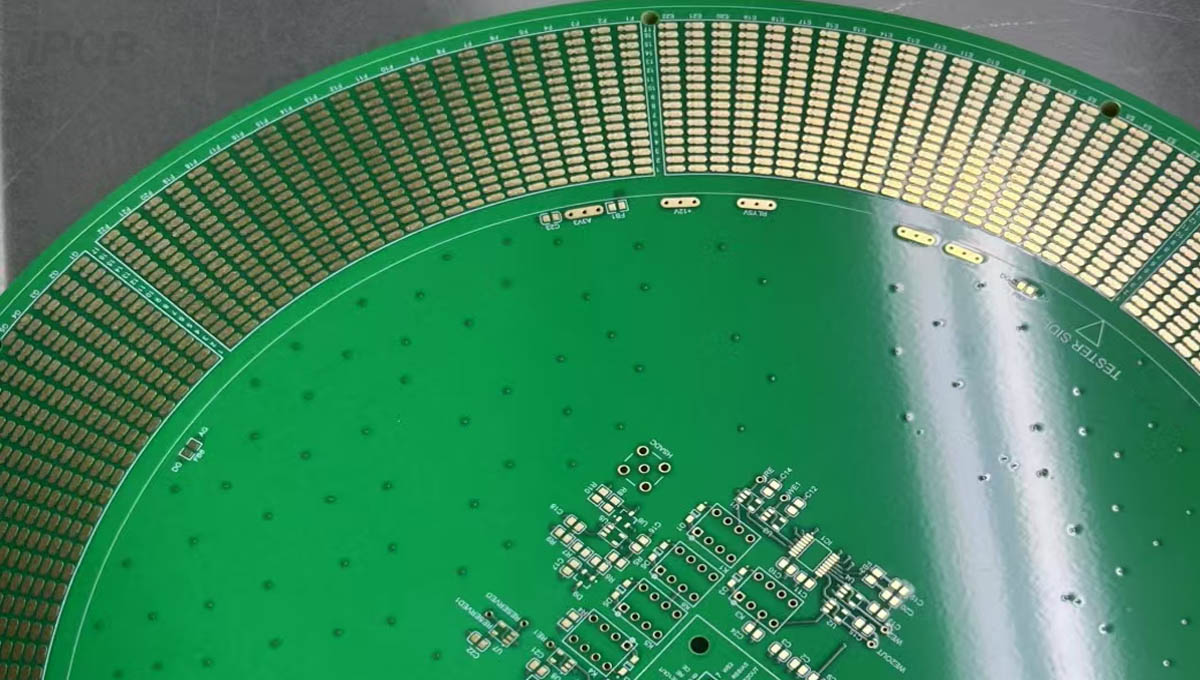

fr4 pcb

Ceramic substrate

Features: Ceramic substrates have excellent high temperature resistance, high thermal conductivity, and excellent electrical properties.

Applicable: Suitable for high-power electronic devices, LED lighting, and high-temperature working environments, such as aluminum nitride ceramic substrates with a thermal conductivity of 180-220W/m·K.

Metal substrates (including aluminum substrates, copper substrates, etc.)

Features: Metal substrates have excellent heat dissipation performance, good mechanical strength, and electromagnetic shielding effects.

Applicable: Suitable for power electronics, automotive electronics, and communication equipment that require efficient heat dissipation.

Polyimide (PI) substrate

Features: Polyimide substrate has excellent high temperature resistance, chemical corrosion resistance and good flexibility.

Applicable: Suitable for flexible circuit boards, aerospace and medical electronic equipment.

BT resin substrate

Features: BT (bismaleimide triazine) resin substrate has high thermal stability, low dielectric constant and loss.

Applicable: Suitable for high-frequency circuits, high-speed data transmission systems and precision electronic equipment.

When selecting PCB materials, it is necessary to comprehensively consider the specific application requirements and environmental conditions to ensure that the selected materials can meet the performance expectations and reliability requirements of the circuit board. Specifically, the following six key factors need to be considered:

1. Electrical performance: Evaluate the dielectric constant, dielectric loss and insulation resistance of the material to ensure that it meets the circuit design requirements.

2. Thermal management: Consider the thermal conductivity and heat resistance temperature of the material to ensure effective heat dissipation and prevent overheating damage.

3. Mechanical strength: Select materials with appropriate strength and toughness according to the application scenario to meet the physical durability requirements.

4. Cost-effectiveness: Comprehensively weigh the material cost and processing cost to achieve a balance between performance and cost.

5. Application environment: evaluate the stability and durability of materials under specific environmental conditions (such as high temperature, high humidity, chemical corrosion, etc.).

6. Long-term reliability: examine the reliability performance of materials during long-term use to ensure stable operation of the system.

Since its establishment, AP Circuit has always adhered to the principle of quality first, using internationally renowned brand A-grade boards such as Rogers, Taikangli, Shengyi, F4BM, etc. with sufficient inventory and fast delivery to ensure high-quality PCB circuit board manufacturing.