High frequency pcb materials achieve the best electrical and mechanical performance of high frequency circuit boards through continuous and careful deployment of raw materials.Over the years,many different formulation combinations have been developed for making RF high frequency board materials.Through these efforts,a variety of circuit board materials have emerged to accommodate a wider range of high-frequency applications and higher performance requirements.

PTFE PK FR-4,the choice of high quality or low price

For users of RF high frequency boards,the most familiar RF high frequency pcb material is polytetrafluoroethylene,which is the familiar PTFE.This is a thermoplastic fluoropolymer synthesized from carbon and fluorine.With its high molecular weight and low coefficient of friction,this material is often used to create "non-stick" surfaces,which is the main reason for its widespread use. PTFE has a dielectric constant (Dk) of 2.1 and has excellent dielectric performance at microwave frequencies.

PTFE has been used as the "building block" material for microwave RF high frequency boards for a long time.In order to meet the different needs of high frequency circuit design engineers,it can be mixed with other raw materials to achieve the purpose of changing its electrical and mechanical performance. For example,adding reinforced glass cloth to PTFE circuit materials can improve their mechanical stability. The added glass cloth material will increase the dielectric constant value of the circuit board material, and also reduce the expansion efficiency of the material (the material expansion coefficient is a function of temperature), thereby better matching the coefficient of thermal expansion (CTE) of the circuit material and its surface copper conductor ). PTFE high-frequency plates can also use ceramic fillers to obtain higher dielectric constant values and fine-tune other aspects of the material,such as CTE values.

In the past period of time, the choice of high-frequency board materials for high-frequency,thin-film circuits has almost been an "either-or" decision for circuit design engineers: use lower manufacturing cost FR-4 circuit materials or use higher performance (meaning higher cost) PTFE high frequency board (in the case of high frequency, use alumina ceramic substrate thick film circuit). FR-4 actually usually refers to a series of circuit materials based on glass cloth fiber reinforced flame retardant epoxy resin. This material is popular with Flowserve due to its low cost and ease of circuit processing, but its electrical performance deteriorates severely at higher frequencies (usually above about 500MHz). Therefore, many circuit design engineers have summarized their own "cutoff frequency point". Below this frequency, use FR-4, and conversely, above this cutoff frequency, use PTFE RF high frequency board.

Although PTFE has been widely accepted by everyone and has a long-standing reputation in high-frequency circuit applications, PTFE material is only one of the many high-frequency RF high-frequency board "members" currently available. There are other thermoplastic materials such as polyphenylene ether (PPE), polyphenylene oxide (PPO) epoxies; and hydrocarbon thermosets with ceramic fillers. Some high-frequency and high-speed applications have encouraged the development of other more distinctive RF high-frequency board materials, such as liquid crystal polymer (LCP) materials for flexible circuits and polyethers for extremely high operating temperatures (approximately +200°C) Etherketone (PEEK) thermoplastic material. In fact, for circuits applied at microwave frequencies, the variety of circuit board material options seems to be increasing with the improvement of technology, but the new material improvements are mainly targeted at some key characteristics of the printed circuit board (PCB), including the dielectric constant (Dk), loss factor (Df), coefficient of thermal expansion (CTE), dielectric constant thermal stability coefficient (TCDk), thermal conductivity, water absorption and long-term aging characteristics, etc.

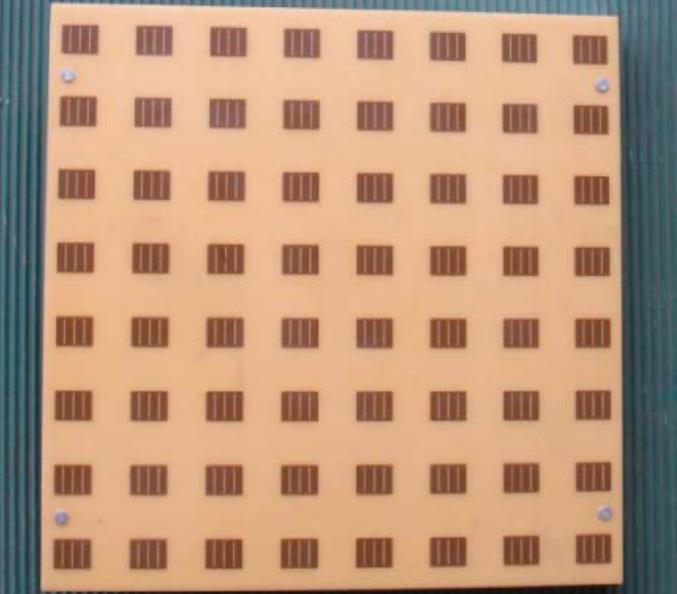

high frequency pcb

Comparison of the composition of RF high frequency board materials

What are the differences in the composition of these different high-frequency materials? First, it’s worth noting that not all PTFE materials are created equal. Early PTFE high-frequency plate materials were reinforced with glass cloth to reduce the inherent coefficient of thermal expansion (CTE) of PTFE. The performance of PTFE RF high-frequency boards is further improved by adding microfiber glass to the material mix, such as Rogers Corporation's RT/duroid 5880 PTFE fiberglass circuit board. Furthermore, by adding special ceramic materials as fillers, the high-frequency plate performance of PTFE is further improved. Not only does it change the original dielectric constant (Dk), but it also changes certain other properties of the material so that it is easier to process when manufacturing PCBs.

For example, Rogers' RT/duroid 6002 PTFE ceramic circuit board material is a PTFE material, but it does not contain glass fiber. By adding special ceramic fillers, the dielectric constant of this PTFE material was increased to 2.94 with a high degree of consistency (within ±0.04), while also having a low Df (0.0012) and a Z-axis CTE value very close to copper Due to the characteristics of the expansion coefficient, the reliability of this via is better. In fact, in the process of adding ceramic fillers to PTFE materials, the final dielectric constant value of the material can be "fine-tuned", which allows this PTFE RF high-frequency plate to be formulated with many different dielectric constant values.

Through experiments, it was found that ceramic fillers can also be used to fine-tune the dielectric constant value of circuit materials other than PTFE, such as Rogers' TMM series of thermosetting hydrocarbon high-frequency plate materials. By adding different amounts and types of ceramic fillers, TMM high-frequency plates can obtain dielectric constant values from 3 to 13. Although this resin material is easier to process than PTFE circuit high-frequency boards, it will also bring some other problems to circuit processing because it is not reinforced with glass cloth. To overcome these challenges, Rogers introduced RO4350B circuit board material, which is also based on a hydrocarbon resin with ceramic fillers, but it is also reinforced with glass cloth. Therefore, RO4350B hydrocarbon ceramic material has good CTE and temperature stability, while maintaining the same easy PCB processing characteristics as hydrocarbon (non-PTFE) circuit high-frequency boards.

Many of the latest material formulations include RF high-frequency boards of thermoset hydrocarbons PPE and PPO, often reinforced with glass cloth to improve their mechanical stability. As mentioned earlier, this material offers unique advantages such as easier processing and improved long-term aging properties. But compared to PTFE-based materials and ceramic-filled hydrocarbon high-frequency plate materials, these new materials have lower dielectric constant (Dk) values and dielectric losses (Df) increase sharply with increasing frequency.

By sampling RF high-frequency board materials with different formulas, some differences in material selection can probably be summarized. For example, whether glass cloth is added to the material and whether special ceramic fillers are added. Adding special ceramic fillers to the PTFE material helps to improve the performance of the CTE and Dk parameters; the addition of ceramic fillers can also make the Dk value of the PTFE RF high-frequency plate reach a larger range (approximately from 3 to 10) . Without ceramic fillers, PTFE achieves better loss characteristics (low Df), but has inferior CTE and Dk performance compared to ceramic filled materials. In general, PTFERF high-frequency boards with higher Dk values will exhibit higher Df values and become more anisotropic with increasing Dk.

Ceramic-filled hydrocarbon RF plates reinforced with glass cloth generally have better CTE, Dk and thermal conductivity than PTFE materials, but higher Df (meaning greater losses) than PTFE materials. PPE and PPO line materials generally have higher Df values than PTFE lines and are approximately the same as hydrocarbon materials at frequencies of 10 GHz or less. PPE and PPO circuit board materials have some special properties, such as excellent long-term aging properties, but they are more water absorbent than other types of high-frequency RF boards.

For RF design engineers, there are now more choices than ever for RF high-frequency boards, each with its own pros and cons. The selection process can often be expedited and simplified by clarifying specific application requirements.