In the process of making high-quality mixed-pressure high-frequency PCB, the selection of high-frequency PCB materials is undoubtedly the primary consideration. Rogers series PCB materials such as RT5880, RO3003, RO4350 and RO4003 are all high-performance high-frequency PCB materials widely recognized by the industry. However, simply choosing high-quality PCB materials is not enough to ensure the quality of the final product. The thickness of each layer of PCB materials, the PP sheets used, and the overall stacking thickness all need to be carefully calculated and considered.

The biggest difference of mixed-pressure high-frequency PCB is that the boards with different media are pressed together. The electrical properties of mixed-pressure high-frequency PCB are different, such as dielectric constant and loss factor. Of course, we set the goal clearly. Suppose I use the surface layer to refer to the second layer, or I can fully enjoy the performance brought by the high-speed board. However, mixed-pressure high-frequency PCB will have some difficulties in processing, mainly because the thermal properties of different boards are different, such as tg value, so that when pressing, each place will be heated slightly unevenly, which may increase the warpage. In addition, the laminated board stacking is generally not very symmetrical, which will also increase the warpage.

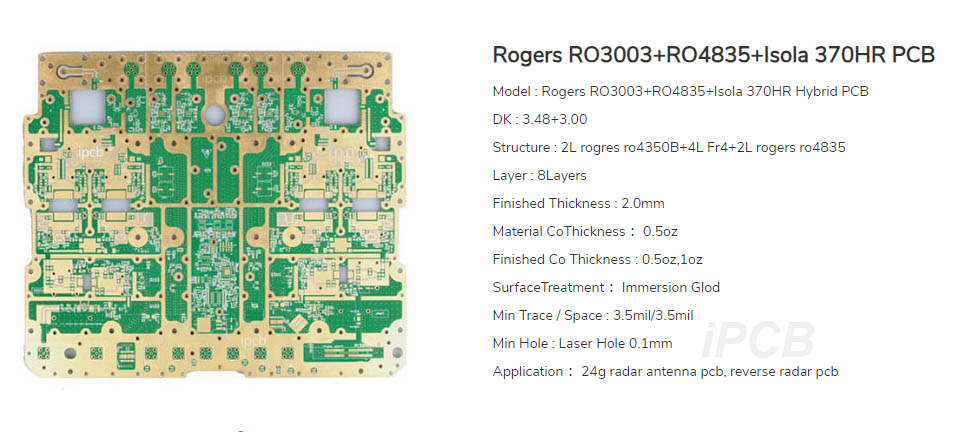

mixed-pressure high-frequency PCB

Multilayer circuit boards are divided into pure pressing and mixed pressing. Pure pressing means that the core boards used in the stacking are exactly the same. Mixed pressing means using different types of core boards for stacking. Pure pressing will be faster because pure pressing is to process the circuits on different layers of core boards together on the same large core board, then cut them and press them together. Mixed pressing requires different types of boards to be processed separately and then pressed together. There are fewer pure pressing processes, so the board making will be faster. Generally, pure pressing uses RF boards for pressing. Mixed pressing is sometimes a mixture of high-frequency boards and FR4 boards. FR4 boards are cheap, so sometimes the cost of mixed high-frequency PCBs is lower.

For high-frequency PCB buyers and designers, how to select high-frequency circuit board manufacturers that truly meet their needs from a lot of complex information is a test. In cooperation with iPCB, what aspects should we collect to make a wise choice?

1. The choice of raw materials is undoubtedly crucial. iPCB is well aware of the needs of different users and the diversity of PCB performance requirements. Therefore, it has various types of high-frequency PCB materials available all year round, such as: high-frequency PCB circuit boards, Rogers/Rogers high-frequency boards, Taconic/Taconic high-frequency boards, F4B/Teflon high-frequency boards, microwave radio frequency boards, special circuit boards, etc. Its dielectric constant ranges from 2.2 to 16. We have high-quality high-frequency PCB material suppliers to ensure that each PCB high-frequency board can operate stably and efficiently to meet your various needs. We have a variety of models such as RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006 and RT6010, etc. These materials have excellent electrical and mechanical properties and perform well in high-frequency applications. They are your ideal choice for creating high-quality PCBs.

2. The perfect combination of high-quality raw materials and advanced production technology is the key to iPCB circuits being able to produce high-quality high-frequency boards. We have excellent production technology and advanced high-frequency board production equipment, which can accurately produce and optimize according to the personalized needs of customers, and create more cost-effective PCB high-frequency board products for customers. Every PCB material and every detail we pay attention to is related to the final performance of the product. Therefore, we always insist on using top-level high-frequency material resources to ensure that your products win at the starting line from the source. At the same time, we will continue to be committed to technological innovation and quality improvement to provide you with better products and services.

3. iPCB circuit also focuses on providing customers with high-quality customer experience. From product design drafts, quotations, orders to production, logistics and other links, we have dedicated personnel to follow up throughout the process to ensure that your order receives enough attention and attention in every link. This is our ultimate pursuit of user experience and iPCB circuit's commitment to customers.

4. To ensure the delivery quality of your PCB circuit board, we have formulated strict environmental control quality inspection standards. In each process, we implement a strict first inspection system to ensure impeccable quality. At the same time, we accurately monitor relevant factors and keep detailed records to ensure that every step is under control. We have leading process capabilities and can meet the stringent requirements of high-frequency PCB boards. The mixed-pressure high-frequency PCB we provide has a maximum thickness-to-diameter ratio of 21:1, a maximum copper thickness of 12OZ, and can handle PCB materials with a maximum working board size of 2000x610mm. We can also make 4-layer mixed-pressure high-frequency PCBs as thin as 0.25mm, and support fine processing with a minimum aperture of 0.10mm. In high-frequency applications, our process capabilities are also reflected in the fineness of the minimum line width/line spacing reaching 2mil/2mil. We are proficient in mastering and applying a variety of mature mixed-pressure high-frequency PCB production technologies, including ROGERS/Rogers+FR4, FR4+PTFE, FR4+408HR and ceramic+FR4, etc., to meet the needs of different customers.

iPCB Circuit has more than ten years of experience in the field of mixed-pressure high-frequency PCB production and is proficient in the professional technology of mixed-pressure high-frequency PCB boards. Such as: high-frequency circuit boards, high-frequency mixed-pressure boards, mixed-medium laminates, F4B PCBs, microwave radio frequency boards, and high-frequency microwave boards. We have professional production experience and profound technical accumulation for mixed-voltage high-frequency PCBs used in power dividers, couplers, combiners, power amplifiers, dry amplifiers, base stations, RF antennas, 4G antennas, etc. It is undoubtedly a wise move for users to choose such a rigorous and responsible high-frequency PCB board manufacturer. iPCB is a company with many of the above advantages. We not only have strong "hard power", but also excel in "soft power". We are committed to providing customers with faster, more accurate, more economical and better high-frequency PCB board rapid sample and batch manufacturing services. iPCB circuit is the mixed-pressure high-frequency PCB and RF PCB circuit board manufacturer you have been waiting for, and we look forward to your visit and cooperation.