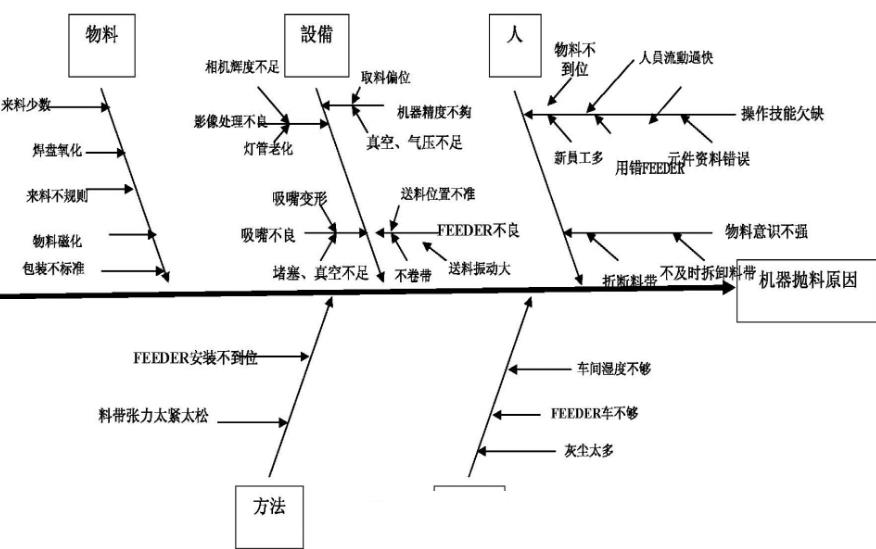

In the SMT often let the factory headache is the material loss problem,SMT material loss has been one of the key controls of the production management staff, then why there are still sometimes material loss, what is the reason? How to prevent these problems in SMT in advance, to minimise the problem.

SMT material loss reasons

1.SMT customer material for the bulk material.Then you need to do through the material to do a comprehensive, one-time purchase data to support.Please fill in the business department and procurement department detailed rectification process and how to regulate the process.

2.SMT material quality is not guaranteed.Please quality,procurement,business (customer materials), engineering (material sampling selection).Fill in the details of the rectification process and how to standardise the process.

3.Quantity shortage.Please procurement,warehouse,business (customer supply) to fill in the details of the rectification process and how to regulate the process.

4.SMT equipment accuracy is not enough.Please fill in the engineering equipment testing,maintenance,programming,detailed programme and time schedule schedule.

5.Personnel operating errors. Production department operators and engineering department's technical training plan.Please administration,production,engineering departments to cooperate,fill in the details of the rectification process and how to regulate the process.

6.Product production, the process of staff operation is not skilled enough,professionalism is not strong.Please submit detailed improvement programme and training plan,training content.

7.SMT materials are not properly stored.Please warehouse,production department responsible person to submit detailed improvement programmes and measures.

8.SMT bulk material management.Please warehouse,purchasing,business department to provide detailed improvement plan and implementation methods.

Reasons for high SMT material loss

SMT material loss is mainly due to irregularities in the operation of the work, before production by the management staff first staff training, standardised working practices to reduce material waste.Quality in the production process to strengthen quality control,to prevent batch size is not the amount.

iPCB provides you with one-stop OEM services from PCB design, PCB layout, PCB manufacturing, PCBA processing, SMT OEM materials, allowing you to save time and energy, production costs and is committed to the research and development of new products and sales.