Regarding how to print a pcb board(printed circuit board), pcb (printed circuit board) has revolutionized the electronics world since its introduction to the market. pcbs not only help you transform temporary circuits created on a breadboard into permanent circuits, but also create a clean and professional appearance.

Option 1: Directly Printing Circuits Using Conductive Materials

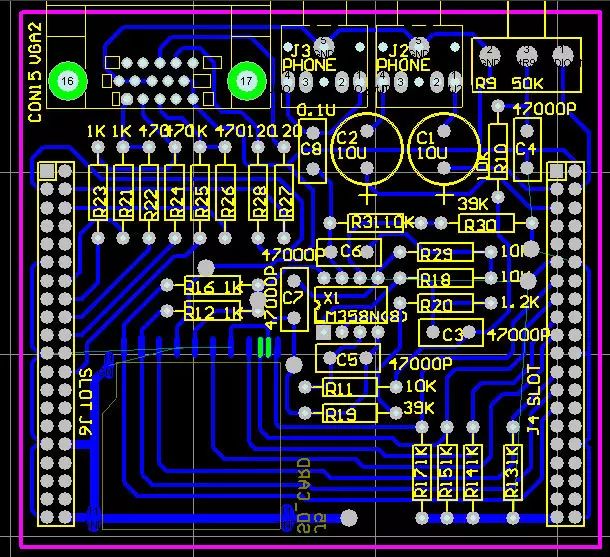

• Designing the Circuit: Use professional circuit design software, such as EAGLE or Fusion 360, to design and model the circuit. Once the design is complete, import the pcb file into slicing software for layer-by-layer slicing to generate a control file that the 3D printer can read.

• Preparing the Material: Use ink or filament infused with conductive particles (such as silver, copper, or graphite) as the printing material. These materials typically come in the form of ink or filament, with ink being the more common choice for commercially available pcb 3D printers.

• Setting Up the Printer: Depending on the selected 3D printer and material, set the appropriate parameters, such as print temperature, print speed, and layer thickness.

• Printing the Circuit: Transfer the control file to the 3D printer and start printing. The printer then prints the designed circuit pattern layer by layer using conductive material to create the circuit.

• Post-processing: After printing, some post-processing may be required, such as removing support structures and cleaning the circuit board.

Option 2: Printing a circuit board with hollow channels or grooves, then filling it with conductive material.

• Designing the circuit board model: Use 3D modeling software to create a 3D model of the circuit board, reserving the hollow channels or grooves in the model for subsequent filling with conductive material.

• Slicing: Import the designed 3D model into the slicing software, slice it layer by layer, and generate printing instructions.

• Select a non-conductive material, such as ABS or PLA, to print the main body of the circuit board.

• Printing the circuit board: Transfer the sliced file to the 3D printer to begin printing the main body of the circuit board.

• Filling with conductive material: After printing, fill the hollow channels or grooves of the circuit board with conductive material (such as conductive silver paste or copper paste). Use a syringe or pen-type filling tool to ensure that the conductive material is fully filled and the surface is smooth.

• Curing the conductive material: Apply a curing method, such as heat curing or UV curing, to ensure that the conductive material forms a stable conductive path.

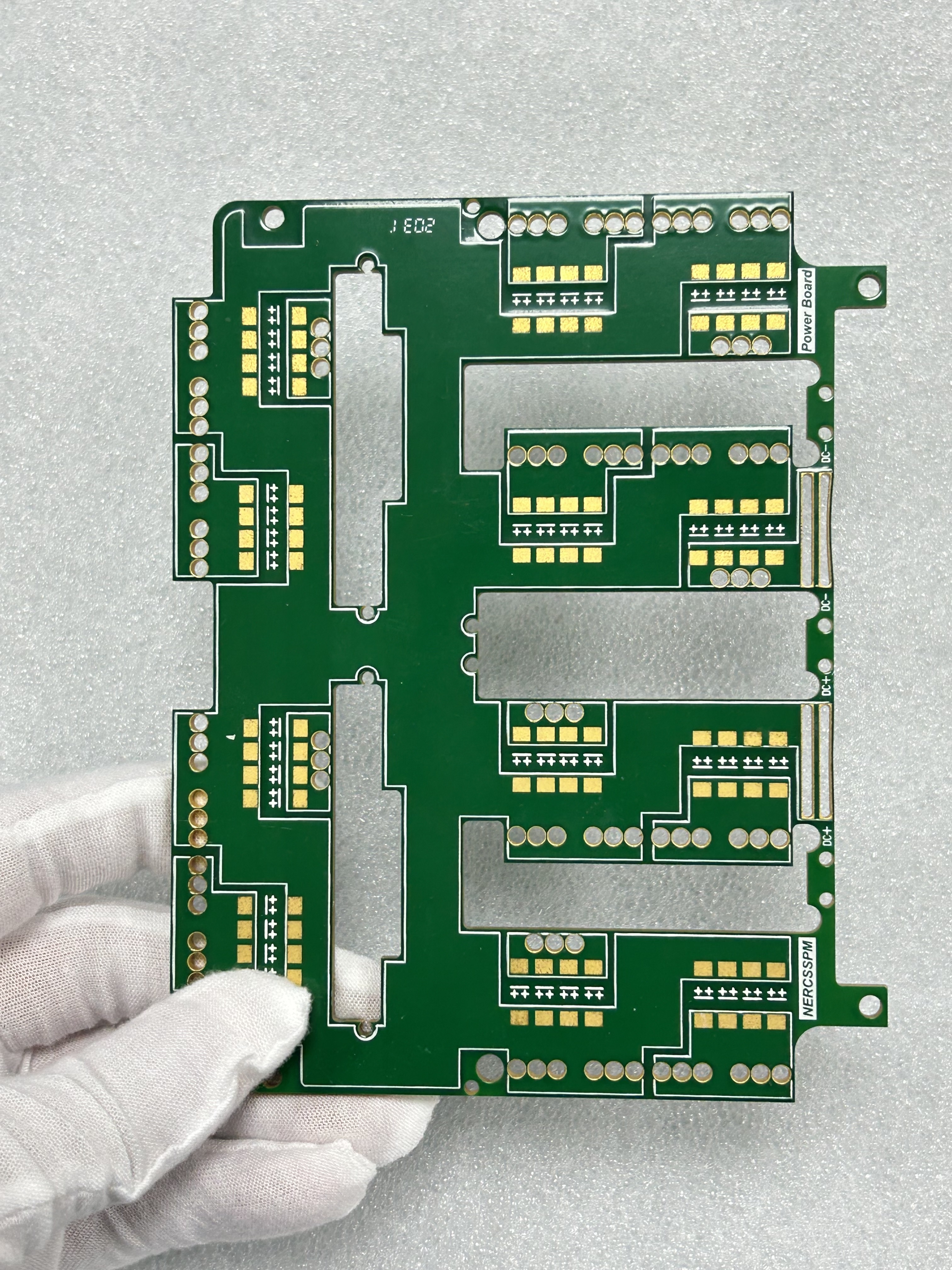

Small-batch pcb printing

Small-batch pcb manufacturing refers to the production of printed circuit boards in small batches. This method is particularly suitable for prototyping, short-run production, and custom products. Due to the smaller production volumes, manufacturers can more flexibly adjust their production processes and respond quickly to customer needs. Furthermore, small-batch pcb manufacturing reduces inventory pressure and mitigates risk. During the pcb design phase, small-batch production helps engineers quickly verify design concepts. When developing new products, engineers often need to iterate through multiple design and testing cycles. With small-batch manufacturing, engineers can quickly receive feedback from each iteration and make adjustments based on test results, thus shortening the product development cycle. This approach not only improves design efficiency but also significantly reduces development costs.

The following are some considerations when printing pcbs:

1. Schematic and Board Design

Before designing a pcb, you need to first create a schematic and determine the required components and connections. Then, convert the schematic into a pcb layout, determine the size and shape of the pcb, and place all components. This step also involves design factors such as the number of layers on the board, via diameter and spacing, and copper area.

2. Prototyping a pcb

To verify the design and identify potential issues, a pcb prototype is necessary. This process involves printing the pcb design onto a transfer circuit diagram and completing it using techniques and tools such as drilling, copper plating, and cutting. When testing the prototype, tools such as a multimeter are needed to ensure that all connections on the board are functioning properly.

3. Producing the Blank, Rubbing, and Etching

Once the prototype is confirmed to be correct, the full-scale circuit board needs to be produced. This process involves using a laser printer to print the pcb pattern onto a transparent film, attaching it to a copper foil surface, and exposing it to ultraviolet light to partially expose the layout on the copper foil surface. Next, the screen is chemically soaked and washed with alcohol or heated tungsten filament, resulting in the final circuit board, which is the standard type of circuit board we often use.

4. Bubble Drilling, Keyhole Slotting, and Other Processes

The final step in circuit board manufacturing involves drilling and other processing, such as microscopic inspection to ensure the integrity of the press-fit components, the accuracy of the stencil, and the proper imaging.

So, how do you print a pcb board? It's far from a simple process. Transforming an abstract idea into a physical object is a delicate journey, and its core lies in choosing a professional, reliable manufacturing partner who can work alongside you. From precise stackup design and impedance control to coordinated component sourcing (BoM), every step requires experience, technology, and dedicated investment. ipcb's engineering team will expertly review your files, optimize your production plan, and offer competitive pricing and fast delivery.