The current new energy vehicle module system consists of many parts, such as batteries, VCU, BSM, motors, etc., but these are relatively mature products. Vehicle module manufacturers have developed many, but there is one module that needs to attract attention in the industry. The most important thing is the IGBT (Insulated Gate Bipolar Transistor), the core electronic component of the motor drive part.

As the CPU in the power electronics industry, IGBT (Insulated Gate Bipolar Transistor) is internationally recognized as the most representative product in the electronic revolution. Multiple IGBT chips are integrated and packaged together to form an IGBT module, which has greater power and stronger heat dissipation capabilities. It plays an extremely important role and influence in the field of new energy vehicles.

1.What are three-electric system and electric drive system?

The three electrical systems, namely power battery (referred to as battery), drive motor (referred to as motor), and motor controller (referred to as electronic control), are also regarded as the three major components, which together account for approximately 70% of the total cost of new energy vehicle electronics. The above are the electronic components that determine the core of the vehicle's sports performance.

For electric drive systems, we generally simply refer to the motor, electronic control, and reducer as the electric drive system.

But strictly speaking, according to the prospectus of Jinjing Electric, the electric drive system includes three major assemblies: the drive motor assembly (which converts the electrical energy of the power battery into rotating mechanical energy and is the source of output power), and the controller assembly ( Based on the hardware and software design of power transistors, it controls the working status of the drive motor in real time and continues to enrich other control functions), transmission assembly (reduces the output speed and increases the output torque through the gear set to ensure the continuous operation of the electric drive system in the efficient range).

Working of the electric drive system: When driving a new energy vehicle, the motor controller changes the direct current (DC) released by the power battery into alternating current (AC) (this process is called inversion), allowing the drive motor to work, and the motor converts electrical energy into mechanical energy. Then the wheels of the car are made to run through the transmission system (mainly the reducer). In turn, the process of converting and storing the mechanical energy of the wheels into the battery is kinetic energy recovery.

IGBT (Insulated Gate Bipolar Transistor)

2. How does the IGBT module work?

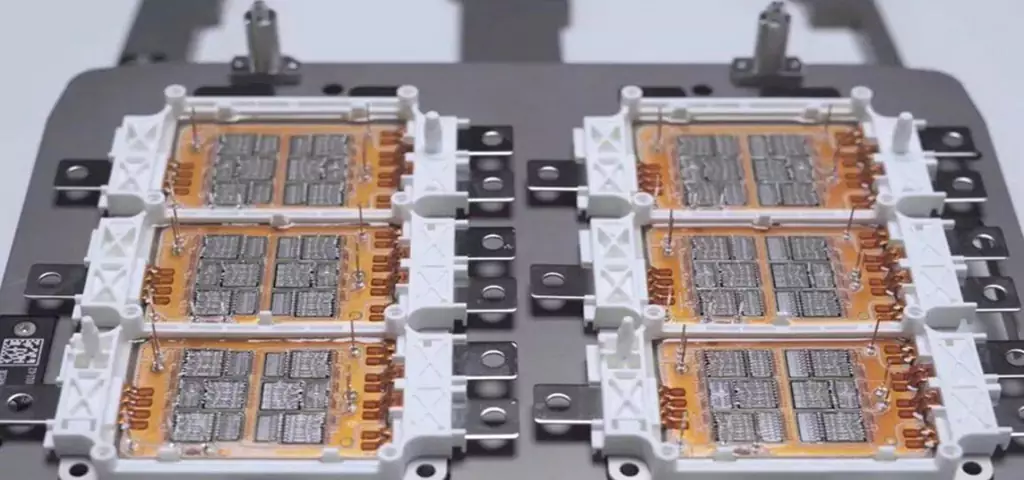

The standard packaging form of the IGBT module is a flat rectangular parallelepiped. The outermost part is a plastic shell, and the bottom is a heat-conducting and heat-dissipating metal base plate (usually copper material). You can see that there are many terminals and pins outside the automotive electronic module, each with its own function.

Among automotive electronic control modules, the IGBT module is the core electronic components of the inverter. Let’s summarize its working principle.

Through the non-on and off transistor characteristics, without considering the transition process and parasitic effects, we regard a single IGBT chip as an ideal switch. We build a parallel and series structure of several IGBT chip units inside the module. When DC power passes through the module, the outflow direction and frequency of the current are changed through the rapid opening and closing of different switch combinations, thereby outputting the AC power we want.

3. Production process of IGBT module

The threshold for the IGBT industry is very high. In addition to the design and production of wafers, the development and production of IGBT module packaging and testing also have very high technological and process requirements. The cross-section interface of the IGBT module and the basic structure of the module in the current shell sealing process are not much different.

The process of IGBT module packaging is roughly as follows:

Lamination -> vacuum reflow soldering -> ultrasonic cleaning -> X-ray defect detection -> lead bonding -> static test -> secondary soldering -> shell filling and curing -> terminal molding -> function test (dynamic test, insulation test, reverse bias test)

For patching, first patch each die on the IGBT wafer to the DBC. DBC is a copper-clad ceramic substrate with ceramic in the middle and copper-clad on both sides. DBC is similar to PCB and plays the role of conductivity and electrical isolation. Commonly used ceramic insulating materials are aluminum oxide (Al2O3) and aluminum nitride (AlN).

Vacuum welding. After patching, the die and DBC are fixed by vacuum welding. Generally, the solder is tin sheet or solder paste.

X-ray void detection needs to detect bubbles, that is, voids, that appear during the connection process. The existence of voids will seriously affect the thermal resistance and heat dissipation efficiency of the device, leading to problems such as overheating, burnout, and explosion. Generally, automotive IGBT modules require a void rate of less than 1%.

Next is the wire bonding process, which uses metal wires to bond the die to the DBC.The most commonly used ones are aluminum wires.Other commonly used ones include copper wires, copper strips, and aluminum strips.

There will be a series of appearance inspections and static tests in the middle. Modules with problems during the process will be scrapped directly.

Repeat the above process to weld and bond the DBC to the copper base plate, followed by glue filling, encapsulation, laser coding and other processes.

Final functional testing will be done before leaving the factory, including dynamic testing of power efficiency, insulation testing, reverse bias testing,etc.

IGBT module

4. What are the common packaging types of automotive IGBT modules?

Econodual series half-bridge packages are mainly used in commercial vehicles. The main specifications are 1200V/450A, 1200V/600A, etc.

HP1 full-bridge package is mainly used in small and medium-power models, including some A-class cars and most A0 and A00 cars. The peak power is generally within 70kW. The main models are 650V400A. Other specifications include 750V300A, 750V400A, 750V550A, etc. .

HPD full-bridge package, used in medium and high power vehicles, most A-class vehicles and above, with 750V820A specifications occupying the mainstream market, and other specifications such as 750V550A, etc.

DC6 full-bridge packaging, an integrated packaging solution based on UVW three-phase full-bridge, has the characteristics of compact packaging, high power density, and good heat dissipation efficiency.

TO247 single-tube parallel connection, there are also a small number of electronic control system solutions using TO247 single-tube packaging on the market. There are two main advantages of using a single-tube parallel connection solution:

1. The single-tube solution can achieve flexible circuit design. Just use the corresponding single-tube parallel connection for the required current, so the cost also has certain advantages.

2. The problem of parasitic inductance is better than that of IGBT The module is easy to solve.

However, there are some difficulties that need to be solved when using single tubes in parallel:

1. It is difficult to share and balance the current between each paralleled single tube, and to ensure consistency, such as achieving simultaneous opening and closing, the same current, temperature, etc.

2. The customer's system design and process are very difficult.

3. There are many interfaces and the requirements for the production line are very high.

5. What testing and verification are required for automotive electronic IGBT modules?

The requirements for product performance and quality of automotive IGBT modules are significantly higher than those in the consumer and industrial control fields. Therefore, automotive certification has become the most important barrier to the automotive IGBT module market. Generally speaking, automotive grade IGBTs require about 2 years. Model introduction cycle.

The testing standards for automotive IGBT modules mainly refer to AEC-Q101 and AQG-324. At the same time, car companies will put forward corresponding requirements based on the characteristics of their own models. The main testing methods include: parameter testing, ESD testing, insulation withstand voltage, mechanical vibration, and mechanical shock. , high temperature aging, low temperature aging, temperature cycle, temperature shock, UHAST (high temperature and high humidity unbiased), HTRB (high temperature reverse bias), HTGB (high temperature bias erased), H3TRB/HAST (high temperature and high humidity reverse bias), power Loop, weldability.

Among them, power loop and temperature loop, as representative endurance tests, have extremely strict requirements. For example, the number of power loops may range from tens of thousands to one hundred thousand times. The main purpose is to test the durability of mechanical connection layers such as bonding wires and welding layers. The main failure mechanism during testing is that the thermal expansion coefficients of the wafer, bonding wire, DBC, solder, etc. are inconsistent, resulting in bonding wire falling off and breaking, wafer solder layer separation, and solder aging.

The above is the introduction we shared about the electronically controlled IGBT module, the core electronic component of new energy vehicle electronics.