Printed circuit board impedance is the magnitude of resistance encountered on a circuit board when a current is transmitted through a wire or a signal is transmitted over a transmission line, and it is a complex physical quantity that combines the effects of resistance,inductance,and capacitance,usually measured in ohms (Ω). To manufacture printed circuit boards with controlled impedance, it is necessary to be able to measure impedance.

How to calculate impedance in layout design

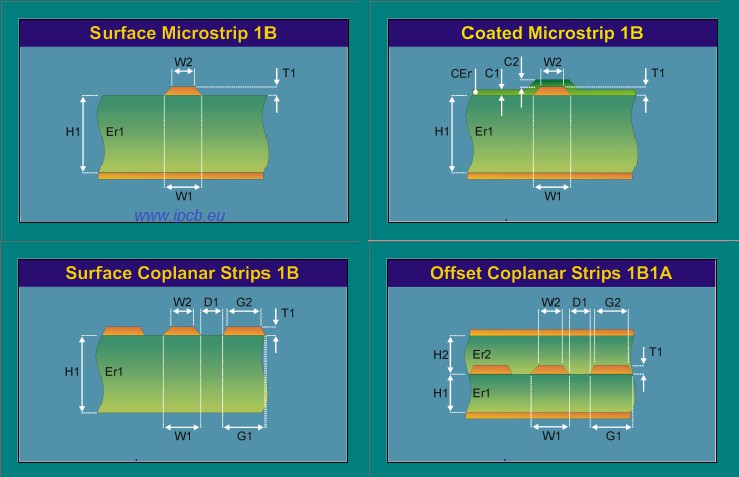

Impedance circuit board refers to a circuit board that requires impedance control. Impedance control refers to a high-frequency signal, a line layer to its reference layer, the signal generated in the transmission of the “resistance” must be controlled in the rated range, to ensure that the signal is not distorted in the transmission process. Impedance control is actually to make every part of the system have the same impedance value, that is, impedance matching. The best way to calculate alignment impedance is to use an alignment impedance calculator. Find an alignment impedance calculator and there are several parameters to consider when determining impedance, including but not limited to:

(1) Dielectric constant

(2) Copper Residual Ratio

(3) Wire width

(4) Wire spacing

(5) Copper thickness

(6) Soldermask thickness

Soldermask will make the outer layer impedance decrease, solder mask thickness and impedance is inversely proportional to the normal printing of a solder mask can make the single-ended impedance down 2ohm, can make the differential impedance down 5-6 ohm, printing two solder masks can be down twice. All boards with impedance should be clearly labeled on the solder resist thickness and the impedance line with or without solder resist oil. Copper thickness is inversely proportional to the positive impedance, increased copper thickness can reduce impedance, and vice versa, Reduced copper thickness can increase impedance, and copper thickness can be controlled by graphic plating or selecting the corresponding thickness of the base material copper foil to control the copper thickness control requirements for uniformity, on the fine line, isolated lines need to be more than compensated for, or divided on the shunt copper block, so that the current balance, to prevent uneven thickness of the copper on the line to prevent the impact of the impedance. Dielectric thickness is directly proportional to the resistance value, increase the thickness of the dielectric can improve the impedance value, and vice versa Reducing the thickness of the dielectric can reduce the impedance value of the different PP (bonding sheet) has a different glue content and thickness, the actual thickness of its compression is not the same, so it is necessary to match the thickness of the H according to the calculated to match the thickness. The dielectric constant is inversely proportional to the impedance, increase the dielectric constant can reduce the impedance, reduce the dielectric constant can increase the impedance, the dielectric constant is mainly controlled by the material material. The dielectric constant is controlled by the material. Different materials have different dielectric constants, which are related to the material used, such as FR4 material, whose dielectric constant is about 3.8-4.8, and the dielectric constant of this material is unstable and not suitable for use in high-frequency circuits.

how to calculate impedance in layout design

Once all the relevant parameters have been calculated, all the above parameters (usually the alignment width) can be adjusted to achieve the desired impedance. Once the impedance is considered to be in an acceptable range, the board can be tested for validity using test specimens fabricated at the same time on the same panel, so good impedance ratings can be obtained without the challenge of accessing the alignment on the actual board. The test specimen alignment should be the same as the circuit board alignment for accurate testing.

Impedance Line Selection and Adjustment: First of all, you need to select the corresponding impedance lines in the board according to the impedance control requirements raised by the customer. When choosing the impedance lines, you need to pay attention to the fact that it is better to select more than one impedance line, but not to miss the impedance line. Move the selected impedance line to another layer, until the impedance calculation is completed, adjust the impedance line according to the results of the calculation, the impedance line by the production capacity to make compensation, and then move back to the board to make the normal production of the required tool film.

Select the impedance layer,find the impedance corresponding to the template, and then enter the original line width line spacing, such as the reference layer in particular, such as compartmentalized reference, you need to manually select the reference layer, and the parameters are entered, click on Calculate.

Impedance Matching:Signal or extensive electrical energy in the transmission process,chosen in order to realize the signal reflection free transmission or maximum power transmission, the circuit connection is required to achieve impedance matching. Impedance matching is related to the overall performance of the system,and the realization of matching can optimize the system's performance.

Impedance matching is to make the microwave circuit or system reflection, carrier traveling wave as close as possible to the traveling wave state of the technical measures. Impedance matching is divided into two categories:

(1) impedance matching between the load and the transmission line, so the load is not reflected. The method is to access the matching device so that the input impedance and characteristic impedance are equal.

(2) Matching between the signal source and the transmission line, divided into two cases: so that the signal source is non-reflective, the method is to access the signal source and the transmission line between the access to the matching device; signal source conjugate matching, the process is to access the matching device between the signal source and the circuit being matched, in this case, mostly belongs to the design of active circuits.

The impedance matching concept has a wide range of applications, impedance matching is common at all levels of amplification circuits, amplification circuits and loads, signals and transmission circuits, and microwave circuits, and the design of the system, whether active or passive, we must consider the matching problem, the fundamental reason is that in the low-frequency circuits are the voltage and the current, and high-frequency is the guided electromagnetic waves do not match will occur serious reflections, damage to the instruments and equipment.