Alumina ceramics are also known as precision ceramics, speciality ceramics, or high-tech ceramics. It is a ceramic that uses highly selected raw materials and is produced in accordance with special manufacturing techniques, which can precisely control the chemical composition and has excellent performance. At present, alumina ceramics are mainly used in high-tech and sophisticated industries, such as microelectronics, nuclear reactors, aerospace, magnetorheological power generation, artificial bone and artificial joints.

In terms of manufacturing technology, alumina ceramics should meet the following three requirements.

①The selected raw materials should be of high purity and the particles should be as fine as possible;

②Strict control of chemical composition.During the manufacturing process,impurities should be prevented from mixing and volatilisation of the components themselves, and the particle size, interface and porosity of the sintered parts should be strictly controlled in order to achieve stable quality and reproducibility;

③Precise shape and size. Alumina ceramic parts are generally not processed and used directly,especially ceramic electronic devices require higher precision.

Alumina ceramics and ordinary ceramics are very different in composition and manufacturing technology.Ordinary ceramics through the raw material preparation, billet forming and kiln firing three processes; and most of the alumina ceramics are manufactured by powder sintering method.In forming technology, due to the extremely high hardness of ceramics,difficult to cut and process, especially for complex shapes of non-contrasting products, such as automobile engines in the supercharger rotor, bones, teeth and so on.

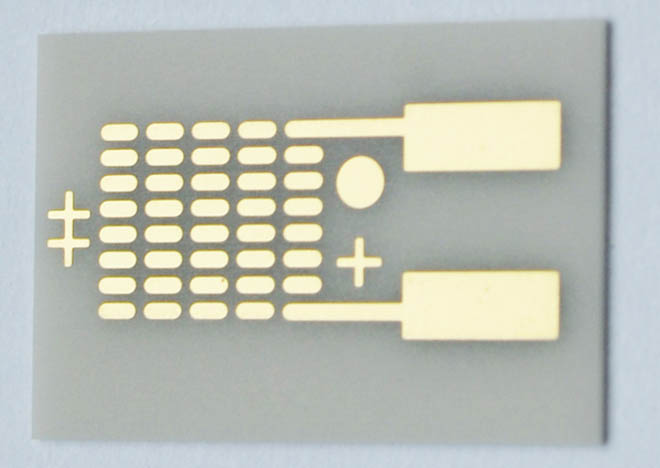

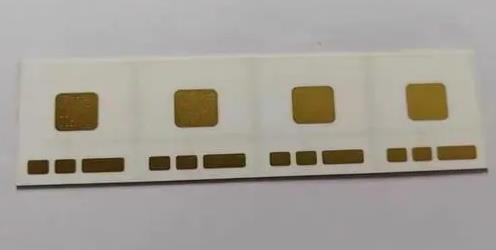

Aluminium oxide ceramic circuit boards

1.Alumina ceramic injection moulding equipment

The injection moulding machine generally consists of plasticising device (or injection device).Mould closing device. Hydraulic device and electronic.Power control device.According to the internal structure of the plasticising device, it can be divided into plunger type and parallel propeller type.In recent years,the latter is generally considered to have more advantages.

The injection moulding machine is composed of an electronic.The injection moulding machine uses the electronic and power control device as the hub,which drives the hydraulic device and at the same time makes the plasticising device and the mould closing device work sequentially. The mould closing device works sequentially. Its working programme is ceramic raw material from the funnel into the cylinder,the raw material in the end of the cylinder at the same time, for melting, stirring, through the cylinder end. Stirring, through the cylinder end of the nozzle injection into the metal mould cavity to obtain blanks.Foreign advanced control system using the screen display pipe (such as the use of oscilloscope. Plasma. Electroluminescent. Liquid crystal), as well as the design of graphic console piping or a combination of the two composite console piping.

Mould materials are generally of high cleanliness.Wear resistance.Alloy steel with excellent corrosion resistance.The mould design should be in accordance with the flow characteristics of the ceramic-polymer system. In order to reduce the shrinkage of the moulding body and to avoid the air inside the mould to be rolled into the moulding body,the outlet of the mould should be controlled. In the case of annular products, the opposite side of the grill is prone to fusion lines, so attention should also be paid to the position of the grill. In order to optimise the injection conditions, it is necessary to rely on the temperature management of the mould. Temperature management of the cylinder, etc., and pressure sensors in the mould should be carefully managed. In addition, there should be a cooling tank on the mould for cooling and heating. Relying on the temperature regulator to keep the temperature of the mould constant is effective in improving the precision of the moulded body. Since a lot of organic materials are used in the raw materials, degreasing without carbon residue is also an important issue in order not to cause thermal cracks in the blanks.

2.Alumina Ceramic Process

The injection moulding principle of ceramics is basically the same as that of plastics.Only a large amount of ceramic powder is mixed in the plastic.In order to improve the injection moulding conditions,it is necessary to select organic materials that match the raw materials used and to choose the amount to be added.In order to obtain a dense and homogeneous injection moulding body,the concentration of ceramic powder should be high.However,too high a concentration will deteriorate the moulding performance.The viscosity of the dispersant polymer system should be reduced in order to improve the fluidity of the mixing blank.As a pretreatment is very important to improve the dispersion of ceramic powder, in order to improve the fluidity of polymer,need to add appropriate plasticiser and lubricant.

The fineness of the ceramic raw material is generally 1 μ m,add the binder (or additives), after sufficient mixing.Stirring.

During the mixing process,the ceramic powder is moistened and coated by the binder,and it all becomes a homogeneous compound before injection moulding.And need to be cooled.Drying.After crushing,the particles are suitable for injection moulding machine funnel feeding.

3. There are four scientific and technological issues that should be noted and mastered in the whole process.

3.1. Fluidity of raw materials

Ceramic particles used in injection moulding are generally composed of 80-90% (important ratio, the same below) of powder and 10-20% of binder.Binder is removed in the degreasing process, and the amount of antique products added to the minimum is appropriate, but it should be noted that if the amount added is insufficient,the forming effect will be affected.In addition,the mobility of ceramic particles in the smaller the fineness.The more the shape deviates from a spherical one, the worse it is. Therefore, the flowability should be tested by as simple a method as possible.

3.2. Defects arising from forming conditions

If the forming conditions are not correct, various defects can occur.The most important of these is the fusion-welded wire, which tends to occur if the moulded body has through holes or blind holes. In this case,it is necessary to pay attention to the design of the mould, especially the type of openings. Position. Size and number. At the same time, attention should be paid to the balance between the injection temperature and speed of injection moulding.

In addition, in order to avoid the occurrence of surface roughness. Cracks. Long stripes. Defects such as deformation.In case of difficult moulding,a self-adjusting controller can be installed in the injection moulding machine for fine control.

3.3. Degreasing

This process is also called removing adhesive, usually the heating rate is 3~5℃/b, about 5~10 days,but when it is carried out under the protective atmosphere of 0.5MPa pressure,the degreasing can be finished in 40 hours.

3.4.Alumina ceramic sintering

Thermal and other parameters can be determined according to the type of ceramic.The line shrinkage rate in sintering is about 15-20%. Cracks are easily formed in the sintering process for work with complicated shapes or thick walls, and care should be taken to prevent them.

4.Alumina ceramic additives

This is one of the most important issues in injection moulding technology.Different forming methods require different additive properties.For example, injection moulding requires degreasing. Fluidity. Gel solubility. Strength. Shrinkage; Extrusion requires plasticity. Gel solubility. Strength. Lubrication cold isostatic pressing (rubber moulding) for lubrication. Granulation.Strength; Mechanical compression requires lubricity, granularity. Strength. Mould release, etc. At the same time,different adhesives should be used for different products.

Aluminium oxide ceramic circuit boards

5.The requirements of additives for injection moulding technology are as follows.

5.1.Gel solubility: It is preferable to use as few additives as possible for all types of forming methods,and it is possible to use ungluing (gel-soluble) additives, which is advantageous for reducing the production cycle and product cost. This is particularly beneficial for the subsequent removal of adhesives.

5.2.Fluidity: Injection moulding requires fluidity under high pressure.The use of resin-based binders gives good injection results, as care should be taken to maintain viscosity and to inject slowly when using resin-based binders.

5.3.Expansion and shrinkage: Since injection moulding uses a large amount of binder,it results in large shrinkage of the blank, which affects the dimensional accuracy and geometry, and is prone to the formation of air holes. In this case, you can choose a kind of paraffin expansion - shrinkage of small substances as additives.This kind of material is smaller than rosin and other amorphous material expansion - shrinkage effect.

As early as the 1950s, Japan used injection moulding technology A12O3 ceramics as ignition plugs for internal combustion engines. Since then, it has been used in the production of small and complex parts. In recent years, people are actively engaged in a variety of heat-resistant. Wear-resistant parts of the development of research,for example,the turbine head of the diesel engine has been ceramicised, is made using injection molding technology.

It is reported that the Institute of Production Technology of the University of Tokyo,Japan has successfully tested the ‘cold injection moulding method’ using only water.This method uses the fluidity and freezing properties of water to solidify and demould ceramics. A mould that has been cooled down to -5 to 10°C is filled with a blank at about 0 to 5°C,and the blank is frozen from the inner wall while it is being filled, and the blank is taken out of the mould when it has reached the strength to be demoulded. Since it is not necessary to use a large number of organic additives as described above, and since there is no need for a long degreasing process, it is possible to shorten the production time considerably, thereby reducing costs. This creates favourable conditions for increasing production.

6.Alumina ceramics strengthening process

In order to strengthen the alumina ceramics and significantly increase its mechanical strength, a new alumina ceramics strengthening process has been introduced abroad. The process is novel and simple, and the technological means adopted is to use electron beam vacuum coating, sputtering vacuum coating or sputtering vacuum coating on the surface of alumina ceramics. Sputtering vacuum coating or chemical vapor deposition method, coated with a layer of silicon compound film, in the 1200 ℃ ~ 1580 ℃ heat treatment, so that the aluminium oxide ceramics toughened. The mechanical strength of the reinforced alumina ceramics can be greatly increased on the original basis, and the alumina ceramics with ultra-high strength can be obtained.

7.Modification method of nano-added alumina ceramics

Alumina ceramics have high mechanical strength, hardness and resistivity. Hardness and resistivity. Good electrical insulation and excellent chemical stability.However, they are brittle and have poor resistance to temperature excursions. By adding nanomaterials to alumina ceramics, the results achieve the purpose of improving and enhancing the comprehensive performance of the products.