What is the thickness of copper foil for PCB manufacturing?

PCB copper foil thickness is generally divided into 1OZ (35um), 2OZ (70um), 3OZ (105um), of course, there are thicker, copper thickness depends on what kind of PCB you do, such as switching power supply to go to the high-current on the 2OZ, the general signal of the 1OZ will be enough.

General dual-panel is 1oz

Multi-layer board inner layer is generally 1/2oz 1/3oz outer layer 1oz 1/2oz 1/3oz

Power supply board copper foil thickness requirements are high

There are many requirements 2oz 3oz and higher.

PCB Copper Foil

How to add copper thickness in PCB manufacturing software?

Can I control the copper thickness of the PCB in the software? This is the first time I have heard, even if there is a PCB manufacturer will not look at this project, because there is no conventional operation, the thickness is not added through the software, customised to the manufacturer, the thickness of the requirements to the manufacturer to explain, can be. If you want to control the copper thickness of the PCB board on the good is to write the requirements clearly, so that manufacturers according to your requirements to produce to control the copper thickness on the line. You just need to do with the board's manufacturers say on it, but it seems not to want how much on how much, there is an upper limit of the value of the current I know of the maximum but 100UM.

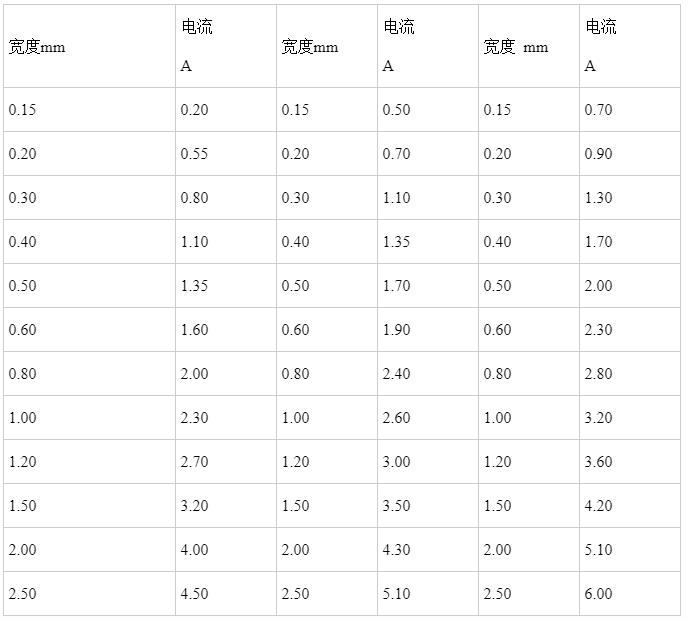

The current strength of the signal. When the average current of the signal is high, the current that can be carried by the width of the wiring should be considered, and the width of the wiring can be referred to the following data:

The relationship between the thickness of copper foil, the width of the traces and the current during PCB design.

The current carrying capacity of different thicknesses and widths of copper foils is shown in the table below:

Thickness of copper foil 35um Δ t=10℃ Thickness of copper foil 50um Δ t=10℃ Thickness of copper foil 70um Δ t=10

Copper Foil Thickness

Note

1.When copper foil is used as a lead wire to pass a high current, the load capacity of the width of the copper foil should be reduced by 50% with reference to the value in the meter.

2.In PCB design and processing,OZ (ounce) is commonly used as the organisation of copper foil thickness.1 OZ copper thickness is defined as the weight of one ounce of copper foil in a square foot area, and the corresponding physical thickness is 35 um; 2 OZ copper thickness is 70 um.

In the PCB industry,1OZ means the thickness of 1OZ of copper uniformly spread over an area of 1 square foot (FT2). It is the average thickness of copper foil expressed in terms of weight per unit area. It is expressed by the formula 1OZ = 28.35g/FT2.

In detail,it and the length can also be said that the thickness of the conversion method as follows:

First,we understand the density constant of copper and the relevant unit conversion formula as follows:

The density of copper ρ = 8.9g/cm3 1 centimetre (cm) = 10 millimetres (mm); 1 millimetre (mm) = 1000 microns (um)

1mil≈25.4um 1FT2≈929.0304 cm2 1mil≈25.4um

According to the formula of mass m= ρ× V (volume) = ρ× S (area) × t (thickness), we know that the weight of the copper foil divided by the density of copper and the area is the thickness of the copper foil!

From the previous section, we know that 1OZ = t × 929.0304cm2 × 8.9g/cm3 = 28.35g/cm2.

So,t = 28.35 ÷ 929.0304 ÷ 8.9cm ≈ 0.0034287 cm = 34.287 um ≈ 34.287 ÷ 25.4mil ≈ 1.35mil

From this, we can see that the thickness of 1OZ copper foil is about 35um or 1.35mil.