What is PCB conformal coating?

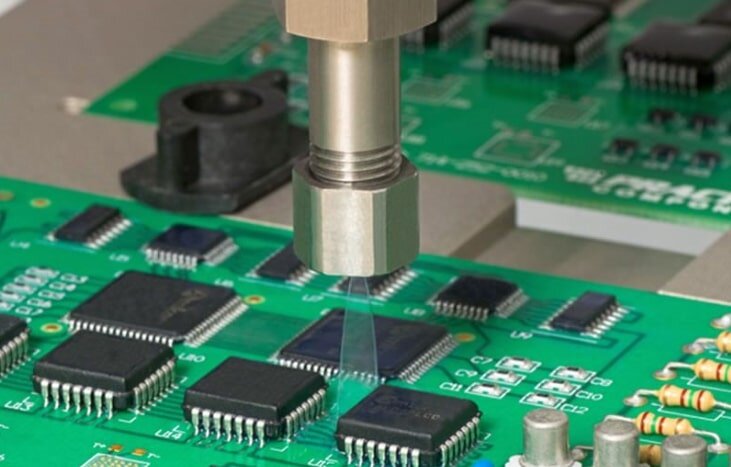

PCB conformal coating is a thin film of protective material applied to a circuit board. The coating protects the entire board and its components. These parts include component leads, exposed traces, solder joints and exposed metal. Conformal coatings protect metal parts from fungus, moisture, spray and other environmental contaminants.

Use of PCB Conformal Coating

The main purpose of PCB conformal coating is to protect electronic components from environmental factors and corrosion. It serves as an insulating material for the PCB and as a protective coating for the PCB;

- It serves as an insulating material for the PCB while minimizing ecological stress during PCB assembly. It helps to eliminate the need for complex enclosures;

- Protecting PCBs from heat, moisture, fungi and airborne contaminants such as dirt and dust.

conformal coat

Advantages of Conformal PCB Coating

Insulation and heat resistance

Lightweight

Protection of PCB components

Reduces environmental hazards to PCBs and prevents ingress of contaminants

Reduced footprint of PCB components

Increased product reliability

Extends the life of PCBs

It is easy to apply

Can PCB Triple Conformal Coating be waterproof and moisture resistant?

It is not easy for PCB conformal coating to be waterproof and moisture resistant at the same time. The main function of PCB coatings is to protect the board from dust, extreme temperatures, chemicals, and mainly moisture. However, PCB conformal coatings do have their limitations. Most layers, whether they are thick or thin, offer a lot of protection against moisture.

Importance of PCB Conformal Coating

PCB conformal coating is necessary, especially in the printed circuit board industry. We still have PCBs minus the conformal coating. Unfortunately, these PCBs have a very short shelf life. There is also some potential for damage when they are used. Don't forget the complete failure of the equipment that relies on them.

As mentioned earlier, conformal coating shields printed circuit boards. It protects them from many damaging effects. Remove them from the field and the shelf life and functionality of our circuit boards will not be as ideal as expected. Using a conformal coating ensures that the boards are always protected.

Types of PCB Conformal Coatings

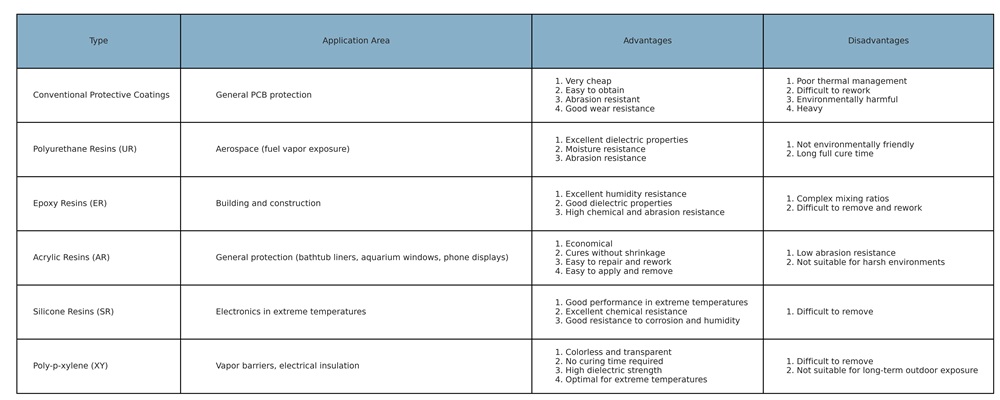

- Conventional Protective Coatings

- Polyurethane Resins (UR)

- Epoxy Resins (ER)

- Acrylic Resins (AR)

- Silicone Resins (SR)

- Poly-p-xylene (XY)

Types of PCB Conformal Coatings

How to choose the right PCB conformal coating?

Having to choose the right PCB conformal coating is one of the most tedious and complicated processes. This is because you may need to analyze a number of key factors before coming to a conclusion. It is risky not to consider the essential aspects. For instance, you may end up purchasing a coating that does not suit your needs. That said, here are some of the basic factors to consider. These factors are critical when choosing the right conformal coating for your project:

- Consider PCB board operating temperatures, highs and lows

The first parameter you may need to evaluate involves the operating temperature range. The reason for this is because it affects the chemicals you have to apply when coating. For example, at high temperatures, it is recommended to use a silicon base. In addition, use urethanes and acrylics. If you are dealing with lower critical temperature resistance.

- Degree of Chemical Resistance

This one is also important. It is easy to remove acrylics for reworking. But unfortunately, they are susceptible to solvent attack. Polyurethane materials tend to offer more chemical resistance, but are not as easy to modify.

- Corrosion Resistance Ratings

How far can a conformal coating go in protecting your equipment as far as corrosion is concerned? Simply put, you must ensure that you only purchase the best layers known for their corrosion resistance.

- Long Shelf Life

Shelf life is the amount of time a product will continue to be useful on the shelf under specified storage, display and distribution conditions. You don't want to buy a product that will spoil after a few days. Unfortunately, some paints are not guaranteed a long shelf life. Silicone triple-anti-paint is one of the best choices because of its long shelf life.

- Performance and Engineering Properties

Before you start choosing the type of coating you intend to use, make sure that it won't stress the components, especially in extreme temperatures.

How to Choose a Quality PCB Conformal Coating?

Globally, electronics and circuits seem to be rapidly miniaturizing. This is an aspect that is associated with an increase in PCB conformal coatings. As mentioned above, conformal coating is necessary to protect PCBs from extreme temperatures, moisture, dust, etc. But how do you choose a high-quality PCB conformal coating material? What do you need to keep in mind to get the best conformal coating material for PCBs?

Here's what you need to keep in mind when choosing a high-quality conformal coating to ensure the best results:

The surface must have excellent flexibility

It should also have low toxicity and cost

It should be easy to rework

Have a wide operating temperature range

It should be able to cure at high speeds without producing by-products

It must protect the board from low/high temperatures and mechanical shock

It must have a long shelf life

It must be easy to apply and have low viscosity

Are you looking for the best conformal coated printed circuit boards that are universally applicable in the market?

If so, then you can contact us and we can discuss any questions you may have about protective coatings for PCBs together. We hope that this article has been helpful to you and then we will be happy to!