Printed Circuit Board (PCB) is known to many as the mother of electronic products, it is the key components of computers, cell phones and other consumer electronics, in the medical, aviation, new energy, automotive and other industries have a wide range of applications, almost every day we are experiencing the convenience of electronic products. Looking at the brief history of PCB development, every technological advancement has directly or briefly affected all mankind.

PCB Enlightenment Stage (1900~1920s)

Before the birth of PCB, any electronic equipment contains many wires, which are not only entangled together, taking up a lot of space, but also short-circuiting is not uncommon. The first person to introduce the concept of PCBs was German inventor Albert Hansen. He pioneered the use of the concept of “wire” for telephone switching systems, metal foil for cutting line conductors, then paraffin paper glued to the top and bottom of the line conductors, and set up holes at the intersection of the lines to realize the interconnection of electricity between the different layers, but also laid the theoretical foundation for the manufacture and development of PCBs.

PCB Development Stage (1920s-1940s)

In 1925, Charles Ducas from the U.S. came up with the unprecedented idea of printing circuit patterns on insulated substrates and then plating them to create conductors for wiring. The technical term “PCB” was derived from this, and this method made the manufacture of electrical devices much simpler.

In 1936, Paul Eisler is regarded as the “Father of Printed Circuits” for being the first to publish thin-film technology and for developing the first printed circuit boards for use in radios. The method he used was very similar to the method we use today for printed circuit boards. This method is called subtraction and it removes unnecessary metal parts. Around 1943, his technology was used on a large scale in the United States to create the proximity fuses used in World War II. At the same time, the technology was widely used in military radio.

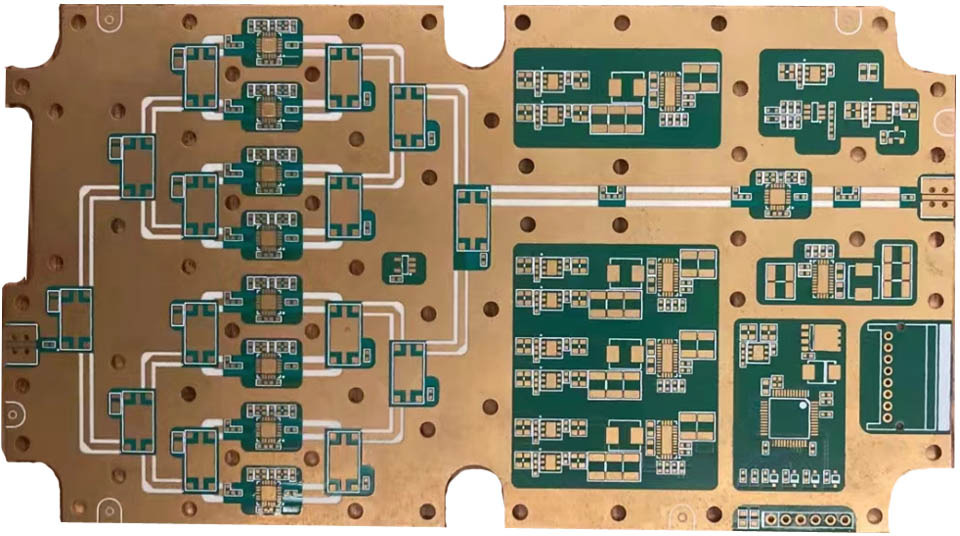

PCB

PCB Commercialization and Spread

In 1948, PCBs welcomed a turning point in their rapid development when the United States officially recognized the invention of the printed circuit board for commercial use. By the 1950s, the U.S. military developed an automated assembly process, which led to mass production and wider use of PCBs among electronics consumers.

Rapid Development Stage (1970-1990):

Around the 1970s, another very important invention appeared - the IC (Integrated Circuit). The first microprocessor was actually invented by Jack Kilby in the late 1950s, but it took him more than a decade to share it with Texas Instruments, which led to the development of the first integrated circuits. With the birth of integrated circuits into the world of electronics manufacturing, the use of PCBs became mandatory.

In the 1970s, multi-layer PCBs evolved rapidly in pursuit of higher precision and density,fine lines with small vias, high reliability, lower cost, and automated production. During that period, PCB design work was still done manually. PCB Layout engineers used colored pencils and rulers to draw circuits on transparent polyester film.To improve drawing efficiency, they produced several package templates and circuit templates for some common devices.

By the 1980s, PCBs were still being drawn by hand, which of course was not very dynamic and only allowed photographs to be used to save and transfer designs. Then computers and EDA (Electronic Design Automation) software came into play, making PCB design dynamic and integrated into PCB manufacturing machines.At the same time, compatible and lightweight gadgets such as Walkmans and cordless phones based on small PCBs, surface mount technology (SMT) began to gradually replace through-hole mounting technology as the mainstream of the day.It also entered the digital age and won people's favor.

PCB Maturity Stage (1990-21st Century)

In the 1990s, electronic equipment continued to shrink, which also led to a greater demand for PCBs for mechanical manufacturing. The Internet was also born, and began a revolution that led to the gradual popularization of personal computers around the world. Later came the introduction of cell phones, without the progress and minimization of PCB technology, this technological leap is not possible.

In the 2000s, PCBs became more complex, more functional, and smaller in size. In particular, multilayer and flex circuit PCB design has made these electronic devices more maneuverable and functional, with small size and low cost PCBs.

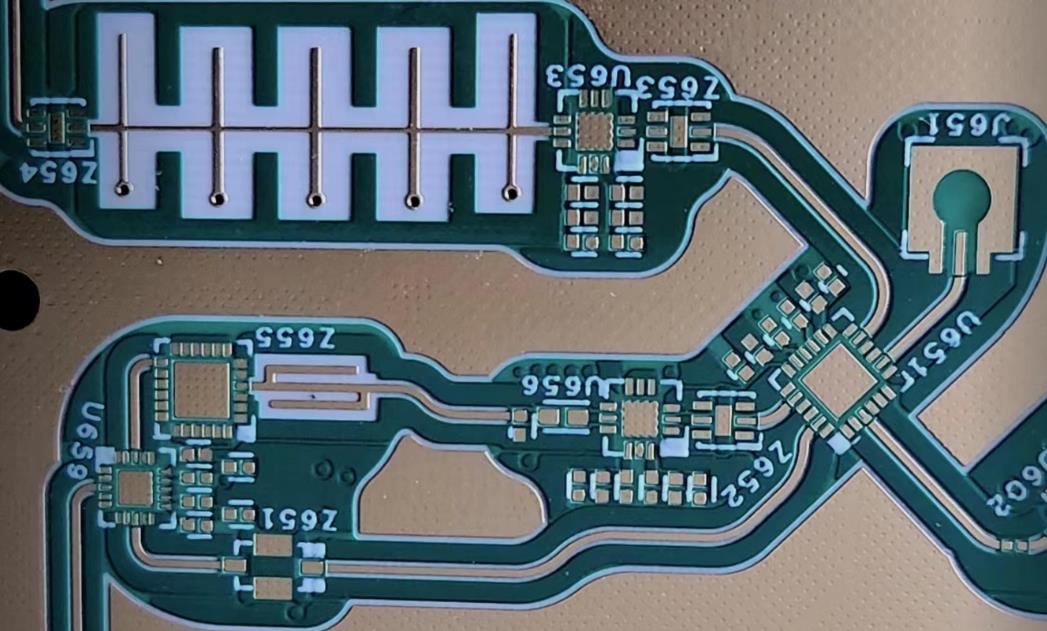

At the beginning of the 21st century, the emergence of the smart phone drove the development of HDI PCB technology. While retaining laser-drilled microvias, stacked vias began to replace staggered vias, and combined with “any-layer” construction techniques, HDI boards reached an ultimate line width/space of 40 μm.

This any-layer approach is still based on a subtractive process, and it is safe to assume that most high-end HDI is still using this technology for mobile electronics. However, in 2017, HDI started to enter a new phase of development, moving away from the subtractive process to a process based on pattern plating.

PCB

Nowadays, various types of printed circuit boards including rigid PCBs, rigid-flexible PCBs, multilayer PCBs, and HDI PCBs are widely used in the market, and after many evolutions, the PCB manufacturing industry is still making great strides. The future impact of PCB is expected to go farther in the following areas.

1.Flexible printed circuit board FPC

Flexible Printed Circuit Board used in a wide range of industries from electronics and telecommunications to aviation, aerospace, automotive and medical, with the passage of time, the demand for flexible PCB will be a rapid increase.

2.High-density interconnection (HDI) PCB

The advantages of high-density interconnect PCB include its reliable and high-speed signal, small size, lightweight. In addition, the HDI PCB in the alignment width is smaller, better density of wiring,囙 engineers can be more functionality and power packed into a small space. The reduced need for layering in HDI PCBs reduces the cost of production. With so many excellent features, high-density circuit boards are becoming an important component of many devices and applications.

3.High power circuit boards

In the fast-growing solar energy and electric vehicles (EVs) industry, driven by the development of high-power PCB (48V and above) is very strong. These high-power boards need PCB to install larger components such as battery packs, while being able to effectively deal with interference issues.

4.The circuit board for Internet of Things applications

The era of Internet of Everything is definitely not a pipe dream, the Internet of Things technology will bring every item to the Internet, and each object can communicate with each other through a common data. It makes people's life more intelligent and convenient. Generally, IoT devices should be equipped with sensors and wireless connections. As a result, PCB manufacturers are developing smaller and more integrated products to fit into the Internet of Things era. To have a sustainable competitive advantage, PCB manufacturers need to keep pace with the times through innovation and comprehensive PCB design, production and testing to meet the growing needs of people.

This issue of PCB development history and future trends will be shared here.