PCBs are essential components of many electronic devices, enhancing their performance. Therefore, PCB manufacturers understand the importance of maintaining PCB quality throughout all stages of manufacturing. Most manufacturers adhere to IPC standards for PCB manufacturing. These standards help them maintain product quality from PCB design to PCB testing and inspection. Today, iPCB will explain what IPC is and what IPC standards are.

What is IPC?

The IPC is a trade organization that standardizes requirements for PCB production and assembly. Founded in 1957 as the PCB Institute and the Interconnect and Packaged Electronics Institute, it has been officially known as the IPC since 1999. The organization publishes industry-wide standards for acceptability in PCB manufacturing, which are accepted worldwide. Currently, the IPC has over 4,800 members. These members include companies specializing in all aspects of PCB manufacturing, from designers and material suppliers to board manufacturers, assembly services, and OEMs.

In the field of PCB (Printed Circuit Board) design and manufacturing, the IPC (Association Connecting Electronics Industries) has established a series of standards to regulate and guide the PCB design and manufacturing process. IPC-A-600 is a document used for acceptance standards that includes requirements for different levels.

IPC

What are the IPC classes for electronic products?

Class 1: This class covers general-purpose electronic products or everyday use products with limited lifespans and simple functions.

Class 2: This class covers dedicated service electronic products with high reliability and long lifespans. PCBs covered in this class are primarily designed for use in general service environments where uninterrupted service is important but not mandatory.

Class 3: This class covers high-performance electronic products that must perform on demand or ensure continuous performance. These products are typically designed for applications where downtime is unacceptable. Additionally, these products are designed for use in harsh environments. This class covers various devices used in the medical and aerospace industries.

What are the differences between the three IPC-A-600 standard classes?

IPC-A-600 Class 1: General electronic products where functionality is prioritized and cost is king.

Applications: Consumer devices (such as appliances, toys, and calculators), non-critical military hardware, etc. Functionality: Ensure basic circuit continuity; cosmetic defects (such as minor scratches and uneven solder joints) are tolerated.

Cost Control: Standard processes (such as hot air leveling and tinning) are used, primarily based on FR-4 substrate.

Design Simplification: Wire spacing ≥ 0.2mm, eliminating the need for complex impedance control.

Typical Uses: Charging management boards for smart wristbands (only required for charging and discharging functions, no consideration for high-frequency interference) and home remote controls (single-panel design with a trace width of 0.3mm).

IPC-A-600 Class 2: Dedicated service electronic products, balancing performance and lifespan.

Applicable Applications: Communications equipment, industrial instruments, automotive electronics, and indoor military equipment.

Long-Term Stability: Requires passing 85°C/85%RH, dual 85°C testing (for at least 1000 hours).

Interference Immunity: High-frequency signals must maintain impedance deviation ≤ ±10%.

Process Upgrades: Available OSP surface treatments (anti-oxidation) and blind and buried via designs (to reduce interference) are possible. Typical examples: (5G base station power modules: required to pass high- and low-temperature cycle testing (-40°C to 125°C), line width tolerance ±0.02mm); industrial PLC control boards (required to operate continuously for 30,000 hours without failure, using a four-layer board structure)

IPC-A-600 Class 3: High-reliability electronic products, zero-fault tolerance design

Applications: Aerospace, military weapons, medical equipment, communications backbone networks, etc.

Extreme environment adaptability: High temperature resistance (-55°C to 260°C), vibration resistance (20G acceleration).

Redundant design: Critical signals require dual-path backup, and power layers are segmented and isolated.

Strict testing: Required to pass HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening). Typical Cases: (Satellite Communication Module: Using Rogers 4350B High-Frequency Base Material (Dielectric Constant 3.5), Loss Tangent ≤ 0.0027), (Pacemaker Control Board: 100% Flying Lead Inspection, Solder Joint Void Rate<5%)

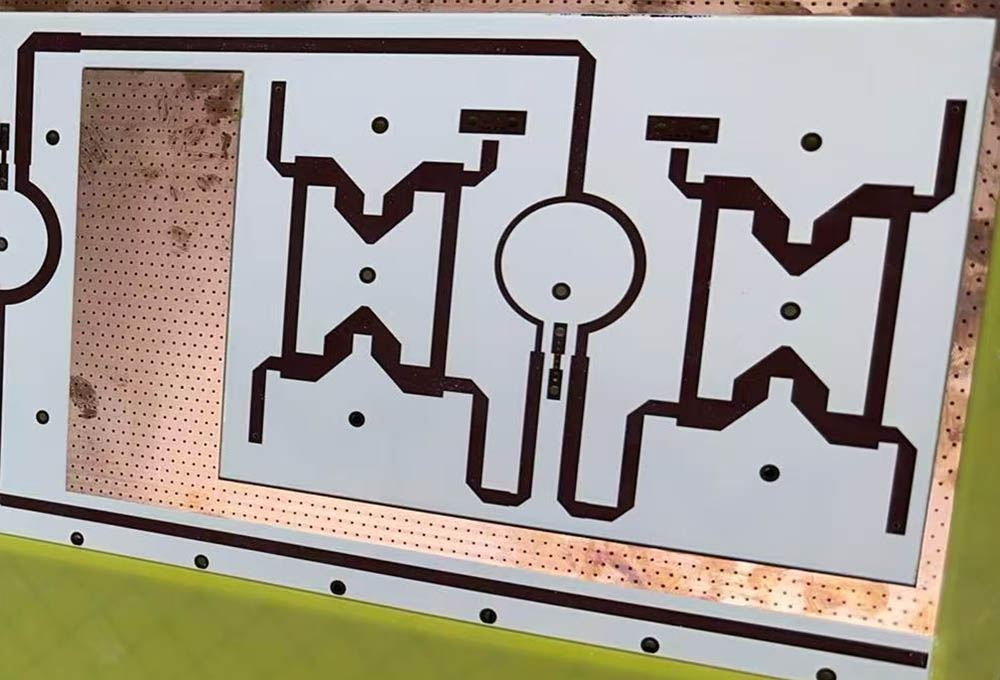

Rogers 4350B pcb

IPC-A-600 Class 3 is more stringent and demanding than Class 2 and is suitable for applications requiring the highest quality and reliability. When selecting a standard, PCB manufacturers and designers need to determine the required IPC level based on the end product's application and requirements to ensure that the PCB design and manufacturing quality meets expectations and achieves the required performance level.

iPCB supports custom PCBs that meet both IPC-A-600 Class 2 and IPC-A-600 Class 3 standards.

The design rules for each IPC standard vary, so manufacturers must consider this when selecting projects that meet these categories. IPC6012 and IPC-A-600 are two well-known IPC standards for PCB manufacturing, covering PCB inspection and performance. During PCB manufacturing and assembly, every manufacturer must reference or adhere to these standards.

IPC-A-600G Acceptance Levels

This specification, also known as IPC-600, establishes acceptance criteria levels for each product category. This specification outlines the target, acceptable, and unacceptable conditions for each product. These conditions can be detected during internal or external inspections. This specification focuses on interpreting the requirements specified in various PCB specifications.

IPC–6012 Performance Requirements for Rigid PCBs

This specification provides a detailed overview of the performance requirements and qualification of rigid PCBs. Rigid PCBs come in a variety of designs, such as single-sided PCBs, active/passive embedded PCBs, metal core PCBs, and HDI boards. This standard broadly categorizes all of these designs and their performance requirements.

How Do PCB Manufacturers Benefit from IPC Standards?

Adhering to these standards will help PCB manufacturers achieve the following benefits:

Maintaining PCB Quality and Consistency: Like any other industry standards, IPC standards for PCB manufacturing are designed to improve the quality of PCB manufacturers. As mentioned earlier, these standards apply to every stage of manufacturing. Therefore, manufacturers who strictly adhere to these regulations can ensure product quality. By adhering to the specifications and their requirements, manufacturers can ensure consistent quality, which ultimately contributes to customer satisfaction.

Ensuring a seamless workflow during manufacturing and assembly: When adhering to IPC standards for PCB manufacturing, it is necessary to follow specific, streamlined, and documented workflows, which helps ensure a seamless workflow within the team. IPC standards also help ensure better communication between suppliers, vendors, customers, regulatory agencies, and others.

Building brand reputation: Understanding the importance of PCBs, most OEMs prefer to work with PCB manufacturing and assembly service providers that adhere to IPC PCB manufacturing standards. This is because these standards help minimize assembly or manufacturing-related errors and produce high-quality products.