Accurate characterization of frequency-dependent inhomogeneous dielectric properties is key to optimizing the design of high-performance and cost-effective PCB antennas. These antennas will be used in a large number of 5G and 6G communication prediction devices. ITEQ IT-88GMW is a high-grade resin system reinforced with tightly woven thin glass fibers to improve the Q-factor of interconnects and passive components on PCB laminates.

The electrical and thermo-mechanical properties of the dielectric material primarily determine the performance of high-speed circuits. Here, it is recommended that characterization methods be implemented to provide information on material performance in real-world applications. Instead of limiting characterization to obtaining only nominal data at a specific frequency by assuming that the signal travels in the direction of optimum performance, it is better to analyze the properties of the material in different directions and positions. This allows the designer to get a clearer picture of the amount of variation expected in practice, rather than the ideal conditions often assumed to simplify the design cycle.

When selecting laminate materials for high-speed, high-frequency antenna designs, the content of the composite material is a key parameter in determining whether the antenna patch and interconnect network can meet the requirements for loss, delay, and impedance matching.PCB laminates are usually manufactured in two ways:

1.With resin impregnated and reinforced glass fiber fabric.

Reinforcing the resin system with non-woven glass fibers or alternative fillers to control the coefficient of thermal expansion.

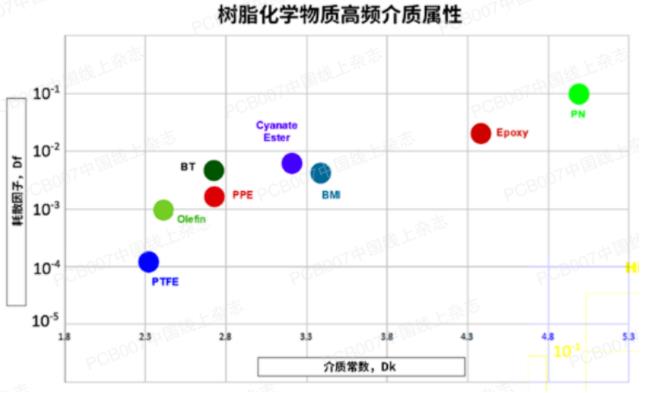

In addition to optimum electrical performance, dielectrics for high-speed, high-frequency applications should be designed for better thermal reliability, dimensional stability and low moisture absorption. The core resin matrix for these systems has evolved from standard epoxy resins to polyolefin resins, which exhibit electrical performance similar to that required for PTFE substrates, but with the risk of low reliability. The following chart summarizes the chemical performance goals of these resins.

Figure 1:Development of the Dielectric Content of Resin Chemicals

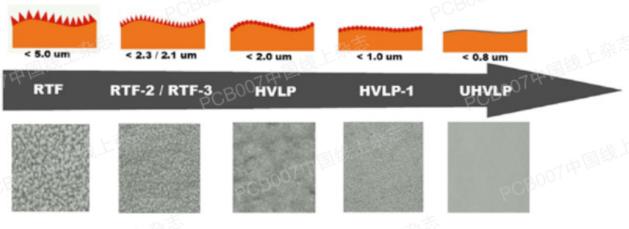

In addition to dielectric properties, conductor loss (due to resistivity and tend skin depth) is an important criterion for laminate selection. The surface roughness of copper plays an important role in the new attenuation observed at millimeter wave frequencies required for 5G and 6G communications. In this regard, copper suppliers have responded to industry demand by significantly improving surface roughness, minimizing skinning effects and increasing peel strength to promote optimal adhesion of dielectric materials to the treated copper foil. The graph below shows the improvement in copper surface topography.

Figure 2:Rz measurements showing copper roughness

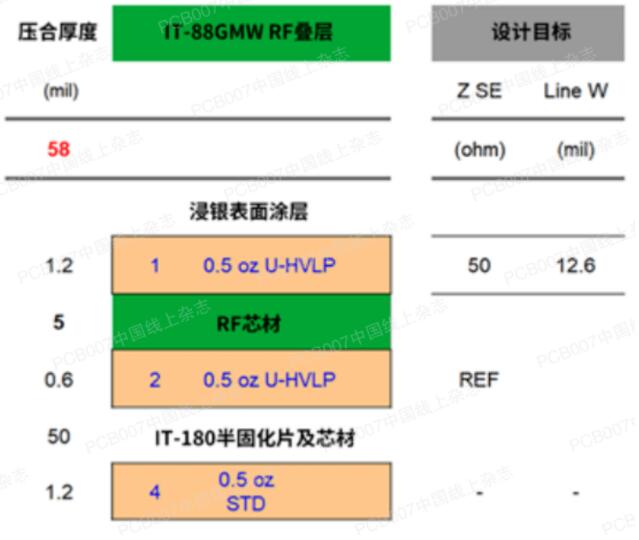

ITEQ and INAOE collaborated to design two test carriers to investigate the sensitivity of patch antenna structures to Dk and Df variations with spatial material inhomogeneities and millimeter-wave frequencies. The 4-layer hybrid stack was designed using ITEQ's IT-88GMW high-performance RF material with a 5 mil core made of 1/2 oz. ultra-low roughness copper.

The critical layer is supported by a non-functional 50 mil standard ITEQ IT-180 High Tg material core and semi-cured sheet to increase stiffness and minimize measurement errors caused by warping or bending of the thinner RF grade performance dielectric core. Stack details, microstrip impedance targets, surface coatings, and layer dimensions are shown in Figure 3.

Figure 3:Sample Layer Structure

Unevenness in the composition of most PCB laminates leads to localized variations in the complex dielectric constant of the material, which in turn affects the performance of the interconnect running at high frequencies. These local variations in the horizontal plane are mainly caused by the fiber weave and have been shown to lead to periodic loading effects exhibited by the transmission line interconnects. The frequency of occurrence of these resonances has been predicted in a comprehensive study by means of rigorous numerical and graphical methods that take into account the spacing between the fiber braid bundles and the alignment angle (relative to the bundle).

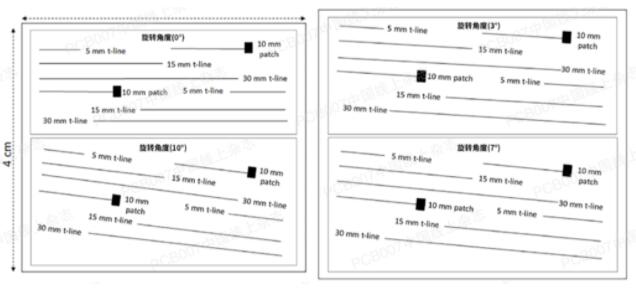

Fig. 4:PCB serialization layout for test carrier fabrication

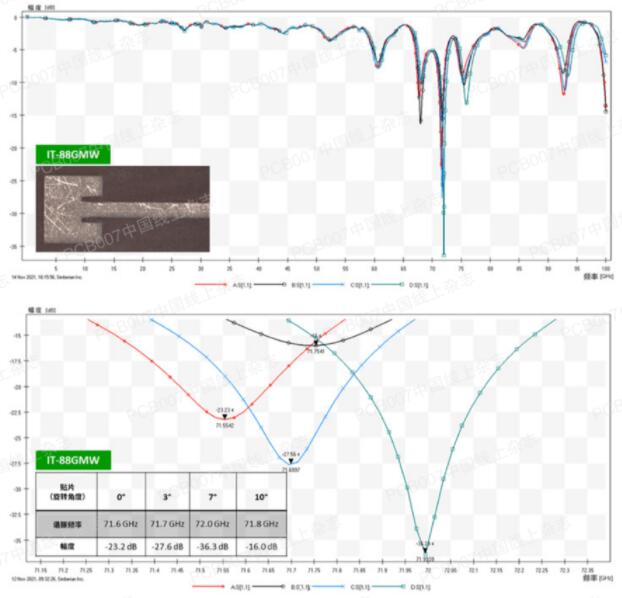

In order to investigate the effect of this periodic loading phenomenon on the patch antenna, the following layout Ф angles (0°, 3°, 7°, 10°) were used to determine the orientation of the microstrip structure with respect to the braided weft line.

Figure 5:Patch Antenna Measurement

Each serialized sample has a transmission line segment terminated at one end (for the RF patch) and at both ends (for the single-ended microstrip line) with a ground-signal ground (GSG) pad,which allows high-frequency S-parameter measurements up to 103 GHz to be performed on antiquities using a coplanar RF probe with a 200-µm spacing.The test structure is as follows:

1.4 sets of 5mm, 15mm and 30mm long microstrip lines oriented at 0°, 3°, 7° and 10° respectively.

2.2 sets of antenna patches, each oriented at 0°, 3°, 7° and 10°,fed by 5mm and 10mm microstrip lines.

The standard deviation of the antennas wired on ITEQ IT-88GMW material from the target resonance frequency is approximately 0.17.The resonance amplitude shows the optimum reflection coefficient (-36.3dB maximum) at all rotational positions (note: for high efficiency patch antennas, the minimum required gain is -10dB).Compared to the material tabulated values (~3.0Dk),the ITEQ IT-88GMW shows a 1.34% change in Dk, reflecting the entire rotation.

The material obtained from this investigation indicates that ITEQ IT-88GMW is an optimal laminate material for W-band frequency antenna designs.