As star products of Rogers' RO4000 series, both RO4350B and RO4003C are glass-reinforced hydrocarbon high-frequency boards, but they cater to diverse scenarios with distinct performance focuses. Below is a detailed comparison of their key technical parameters and application directions.

1. Core Technical Parameter Differences

Electrical Performance

Dielectric Constant (Dk@10GHz): RO4003C is 3.38±0.05, while RO4350B is slightly higher at 3.48±0.05.

Dissipation Factor (Df@10GHz): RO4003C leads with 0.0027, versus RO4350B's 0.0037 — meaning RO4003C excels in reducing energy loss during signal transmission.

Thermal Performance

εr Thermal Coefficient (-50°C to 150°C): RO4003C = 40 ppm/°C; RO4350B = 50 ppm/°C.

Thermal Conductivity: RO4003C hits 0.71 W/m/°K, slightly higher than RO4350B's 0.69 W/m/°K.

Z-axis CTE (-55°C to 288°C): RO4350B dominates with 32 ppm/°C, far lower than RO4003C's 46 ppm/°C, ensuring better dimensional thermal stability.

Electrical Resistivity

Volume Resistivity: RO4003C (1.7×10¹⁰ Mohm) > RO4350B (1.2×10¹⁰ Mohm).

Surface Resistivity: RO4350B (5.7×10⁹ Mohm) outperforms RO4003C (4.2×10⁹ Mohm).

Other Physical Properties

Water Absorption (D48/50%): RO4003C (0.04) < RO4350B (0.05).

Peel Strength (1oz ED Foil): RO4003C = 6.0 lb/in (1.05); RO4350B = 5.0 lb/in (0.88).

Density: RO4350B (1.9 gm/cm³) > RO4003C (1.8 gm/cm³).

Flame Rating: RO4350B is UL 94 V-0 certified, while RO4003C is non-FR — a critical distinction!

2. Product Features & Application Scenarios

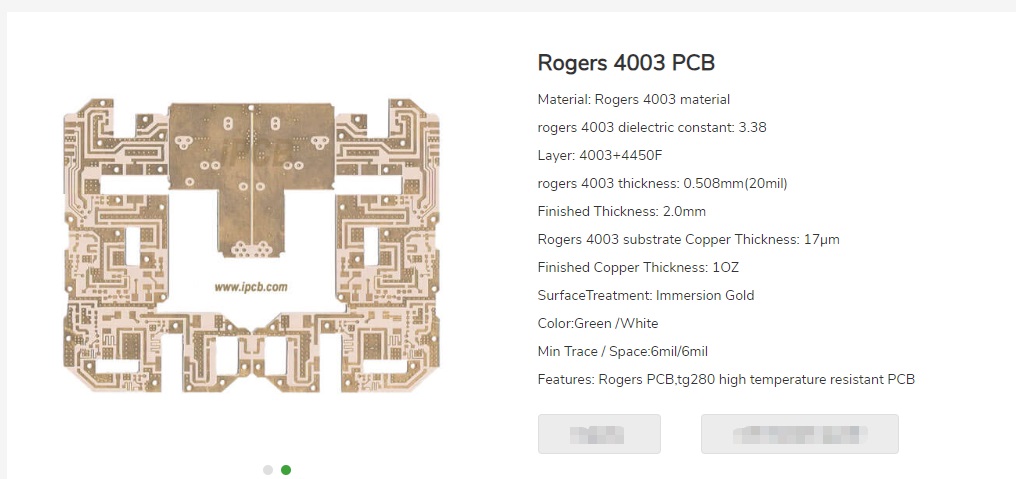

RO4003C: Cost-Effective All-Rounder

Core Features: Ceramic-filled hydrocarbon composite that balances PTFE/glass cloth's excellent electrical performance with epoxy/glass's easy processability. Fully compatible with FR-4 manufacturing workflows and more cost-efficient.

Typical Applications: Ideal for cost-sensitive microwave/RF designs, widely used in high-speed digital circuits, broadband communication systems, automotive ECUs, and civilian satellite communication equipment — delivering performance without breaking the budget.

Figure 1: RO4003 PCB

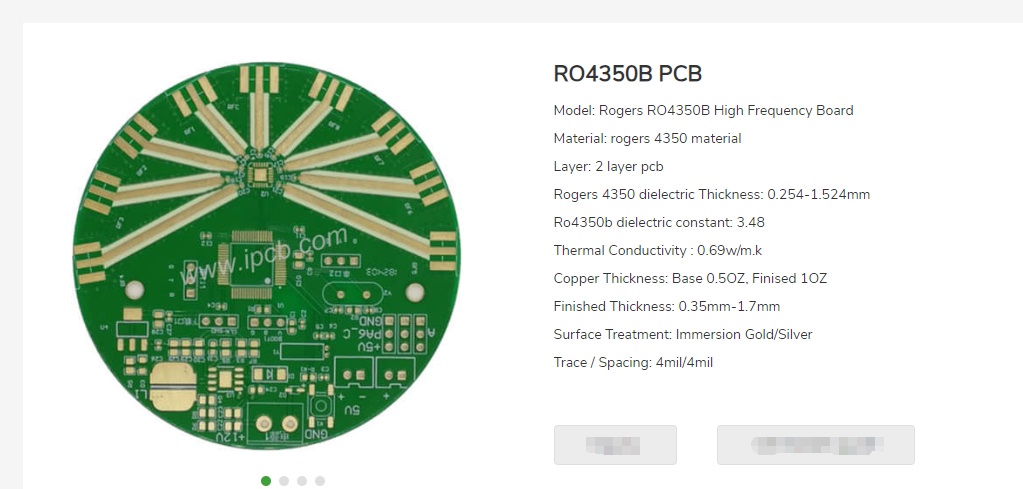

RO4350B: High-Performance Professional Benchmark

Core Features: Market-leading high-frequency board with ultra-tight Dk tolerance control, lower Z-axis CTE, superior dimensional stability, and UL 94 V-0 flame resistance. Maintains reliability in high-temperature/humidity environments.

Typical Applications: Specialized for high-demand scenarios: base station power amplifiers, high-power power circuits, military satellite communication equipment, and dual-use (military/civilian) radar systems — perfect for high-end electronics requiring strict heat dissipation, stability, and flame resistance.

Figure 2: RO4350B PCB

3. Key Selection Guide

Pursuing cost-performance balance & FR-4 compatibility? RO4003C is your pick!

Focused on high-end equipment & need flame resistance/dimensional stability? RO4350B is better!

Together, the two boards form Rogers' high-frequency material matrix, precisely matching different levels of RF/microwave design needs.