(1) The power cord is an important pathway for EMI to enter and exit the circuit. External interference can be transmitted to the internal circuit through the power cord, affecting the RF circuit specifications. In order to reduce electromagnetic radiation and coupling, it is required that the primary, secondary, and load side loop areas of DC-DC modules be minimized. No matter how complex the form of the power circuit is, its high current circuit should be as small as possible. The power and ground wires should always be placed close to each other.

(2) If a switching power supply is used in the circuit, the layout of the peripheral components of the switching power supply should comply with the principle of the shortest power return path. The filtering capacitor should be located near the relevant pins of the switching power supply. Use common mode inductors near the switching power module.

(3) Long distance power lines on a single board cannot simultaneously approach or pass through the output and input terminals of a cascaded amplifier (with a gain greater than 45dB). Avoiding power lines as a transmission path for RF signals may result in self excitation or reduced sector isolation. High frequency filtering capacitors should be added at both ends or even in the middle of long-distance power lines.

(4) Three filtering capacitors are connected in parallel at the power inlet of the RF PCB. Utilize the advantages of these three capacitors to filter the low, medium, and high frequencies of power lines respectively. For example: 10uF, 0.1uF, 100pF. Approach the input pins of the power supply in descending order.

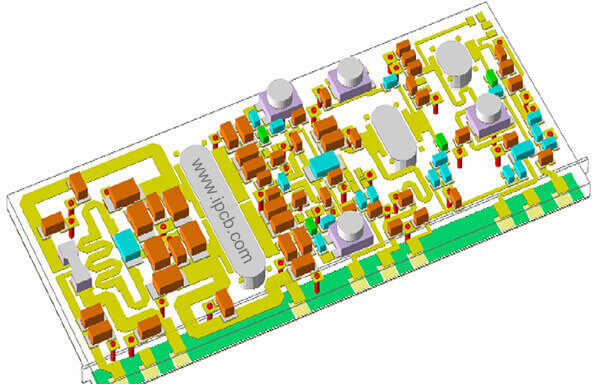

RF circuit board design

(5) When using the same power supply to power a small signal cascaded amplifier, power should be supplied from the final stage to the preceding stages in sequence, so that the EMI generated by the final circuit has little impact on the small signal cascaded amplifier. Reception. Each level of power filter has at least two capacitors: 0.1uF and 100pF. When the signal frequency is higher than 1GHz, a 10PF filtering capacitor needs to be added.

(6) The filtering capacitor should be close to the transistor pin, and the high-frequency filtering capacitor should be close to the pin. Choose a transistor with a lower cut-off frequency. If the transistor in the electronic filter is a high-frequency transistor that operates in the amplification region and the layout of peripheral devices is not reasonable, it is easy to generate high-frequency oscillations at the power output end. The linear voltage regulator module may also have the same problem, as there is a feedback loop in the chip and the internal transistor works in the amplification area. The high-frequency filtering capacitor should be located near the pin to reduce distributed inductance and disrupt oscillation conditions.

(7) The size of the copper foil in the PCB power supply section should comply with the maximum current flowing through it, taking into account the margin (generally referred to as 1A/mm line width).

(8) The input and output terminals of the power cord cannot be crossed.

(9) Pay attention to decoupling and filtering of the power supply to prevent interference between different units through the power line. When wiring the power supply, the power lines should be isolated from each other. The power cord is isolated from other strong interference lines (such as CLK) through a ground wire.

(10) The power cord of the small signal amplifier needs to be isolated from the ground copper wire and ground hole to avoid other EMI interference and affect signal quality.

(11) Different power layers should avoid spatial overlap. In order to reduce interference between different power sources, especially those with large voltage differences, it is necessary to avoid the problem of overlapping power supply planes. If it is difficult to avoid, a sandwich layer can be considered.

(12) The allocation of PCB layers is easy to simplify subsequent wiring processing. For a four layer PCB (commonly used for WLAN), in most applications, components and RF leads are placed on top of the circuit board. The second layer serves as the system ground, with the power supply located on the third layer, and any signal lines can be distributed on the fourth layer.

The continuous grounding plane layout of the second layer is essential for establishing impedance controlled RF signal paths. It is also convenient to obtain the shortest possible grounding circuit, providing high electrical isolation for the first and third layers, thereby minimizing coupling between the two layers. Of course, other layer definitions can also be used (especially when the circuit board has different layers), but the above structure is a proven successful example.

(13) A large power layer can make VCC wiring easier, but this structure is often the trigger for system performance degradation. If all power cords are connected together on a large plane, noise transmission between pins cannot be avoided. On the contrary, if a star topology is used, the coupling between different power pins will be reduced.