PCB Product Introduction

PCB board mainly consists of pads, vias, mounting holes, wires, components, connectors, soldermasks, electrical boundaries, etc. The main inviting functions of each component are as follows:

Pad PAD: A metal hole used for soldering the pins of the components.

VIA: A metal hole used to connect the component pins between layers.

Mounting holes: used to fix the printed circuit board.

Assembly: Copper film used to connect the electrical network of component pins.

Wire Layer: Used to connect components between boards.

Solder Resist Layer: Copper wires used in the ground network to effectively reduce impedance.

Electrical Boundary: Used to confirm the dimensions of the printed circuit board, and all components of the printed circuit board can not exceed the boundary.

Introduction of PCB materials

According to the brand quality grade from low to high as follows: 94HB-94VO-22F-CEM-1-CEM-3-FR-4

Detailed parameters and applications are as follows:

94HB: Plain cardboard, non-flame retardant (material, molded, non-power board).

94V0: Flame retardant cardboard (molded)

22F: Single-sided semi-glass fiberboard (molded)

CEM-1: Single-sided fiberglass board (must be computerized, no punching)

CEM-3: Duplex Half Glass Fiberglass Board (except for duplex cardboard, it is the highest grade of duplex material and can be used for simple duplex panels)

FR-4: Double-sided fiberglass board with distinctive flame retardant and special properties, which can be divided into four types: 94VO-V-1-V-2-94HB.

Semi-cured film: 1080=0.0712mm, 2116=0.1143mm, 7628=0.1778mm

FR4 CEM-3 are glass panels, fr4 are fiberglass panels, cem3 are composite substrates.

Halogen-free refers to halogen-free (fluorine, bromine, iodine and other elements) substrates. Due to the special circumstances of the combustion phenomenon, bromine produces toxic gases that require environmental protection.

Tg is the glass transition temperature or melting point.

FR4 PCB boards must be flame retardant. It cannot ignite at a certain temperature, but only softens. This temperature is called the glass transition temperature (Tg point) and is related to the dimensional durability of the PCB.

What is a High Tg PCB and the advantages of using High Tg PCBs

When the temperature of a High Tg PCB circuit board rises to a certain threshold, the substrate changes from a “glassy” to a “rubbery” state. This temperature is called the glass transition temperature (Tg) of the board. In other words, Tg is the temperature (℃) at which the substrate remains rigid. In other words, ordinary PCB substrate materials will continue to soften, deform, and melt at high temperatures. At the same time, it also shows a rapid decline in special mechanical and electrical properties. This will affect the service life of the product. Ordinary Tg sheet at 130 ° C or more, high Tg is generally greater than 170 ° C, medium ordinary Tg at 150 ° C or so; general printed circuit board Tg ≥ 170 ° C is called high Tg printed circuit boards; substrate Tg increase, the board's heat resistance, moisture resistance, chemical resistance, fastness and stability will increase and improve the higher the value of the TG, the better the temperature resistance of the board, especially in the lead-free process, high Tg application is more; high Tg value, the higher the temperature resistance, especially in lead-free process, the higher the Tg value, the higher the temperature resistance, the higher the temperature resistance, the higher the temperature resistance, the higher the temperature resistance, the higher the Tg value. The higher the TG value, the better the temperature resistance, especially in the lead-free process, the higher the Tg application; high Tg refers to high heat resistance. With the rapid development of the electronics industry, especially with the computer as the representative of the electronic products, high functionality, high multilayer progress, the requirements of PCB substrate materials with higher heat resistance as a prerequisite.

Therefore, the difference between ordinary FR-4 and high Tg: at the same high temperature, especially in the moisture absorption after heating, the material's mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other aspects are different. In addition, the surface finish of high Tg products is better than that of ordinary PCB substrate materials.

Production Scope and Experience

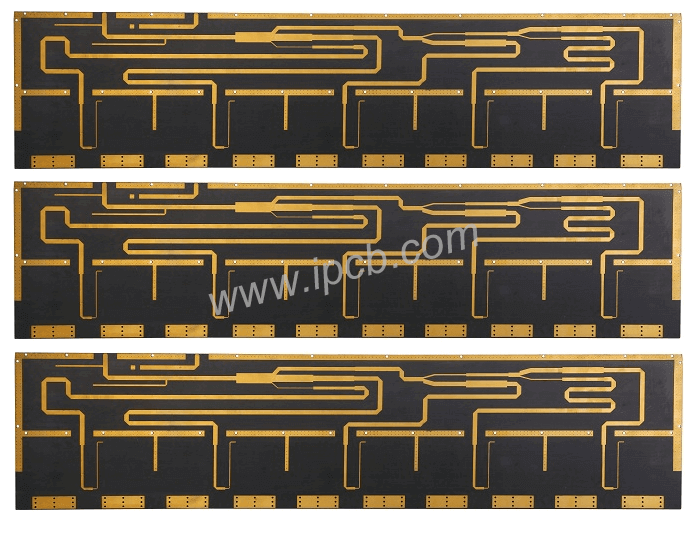

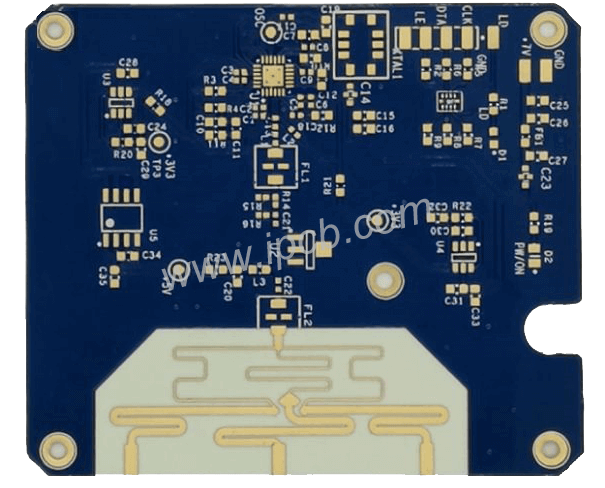

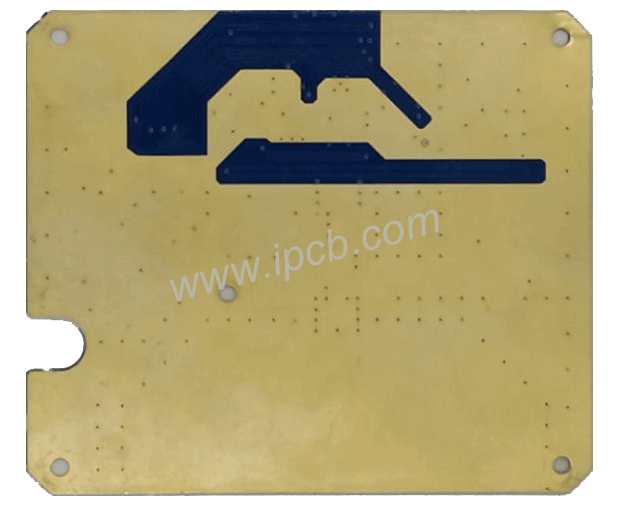

iPCB is a professional PCB circuit board factory, engaged in high-end printed circuit board design, development and production of high-tech enterprises. iPCB adopts the “own production plant + joint venture platform” mode, independent research and development of the industry's first PCB automatic quotation ordering system, combined with its own PCB factories and joint ventures in their respective subsectors, using the Internet + to build the industry 4.0 PCB intelligent factory, to provide professional PCB production services for customers as the goal. iPCB focuses on the development and production of high-end PCB circuit boards. Combining the professional advantages of our own PCB factories and joint ventures in their respective sub-areas, we utilize Internet+ to build the industry's 4.0 PCB intelligent factory, with the goal of providing our customers with professional PCB production services. iPCB specializes in the research and development and production of high-end PCB circuit boards, including microwave high-frequency circuit boards. Products include microwave high frequency circuit boards, high-frequency mixed voltage circuit boards, Fr4 double-sided multilayer circuit boards, ultra-high multilayer circuit boards, one-phase, two-phase, three-phase HDI circuit boards, and any-phase HDI circuit boards, etc. iPCB's circuit boards have been widely recognized as the best choice in the industry.

iPCB's circuit board production process has the following experience:

1.Appearance process: tin spraying, lead-free tin spraying, nickel/gold plating, chemical nickel/gold, OSP, etc. ...

2.PCB number of layers: 1-70 layers

3.Processing plane or object surface size, single-sided / double-sided 2000mmx550mm

4.Board thickness 0.1mm-60mm, minimum line width 0.04mm, minimum line spacing 0.04mm

5.Minimum finished hole diameter 0.2mm

6.Minimum pad diameter 0.6mm

7.PTH hole diameter tolerance ≤ Ф0.8 ± 0.05mm>Ф0.8 ± 0.10mm

8.Hole position difference ± 0.05mm

9.Insulation resistance>1014Ω (normal state)

10.Hole resistance ≤ 300uΩ

11.Dielectric strength ≥ 1.6Kv / mm

12.Peeling strength 1.5v/mm

13.Soldermask hardness > 5H

14.Thermal shock 288 ℃ 10sec

15.Combustion performance level 94v-0

16.Solderability 235 ℃ 3s internal wet warpage t<0.01mm/mm ions cleanliness <1.56 μg/cm2

17.Base copper foil thickness: 1/2oz, 1oz, 2oz

18.Thickness of plating:General 25UM, but 36UM.

19.Commonly used substrate: FR-4, 22F, cem-1, 94VO, 94HB, aluminum substrate, fpc.

20.Customer supplied data: GERBER file, POWERPCB file, PROTEL file, PADS2007 file, AUTOCAD file, ORCAD file, PcbDoc file, templates, and so on.