Whilst many conventional PCBs offer excellent functionality, not all are suitable for LED applications. To achieve optimum performance in lighting applications, PCBs for LEDs must be designed to maximise heat transfer.Aluminium based circuit boards provide a versatile basis for a wide range of high output LED applications. LED lighting solutions are rapidly gaining ground in a variety of industries and are valued for their low power consumption,high efficiency and impressive light output. Most high lighting output LED applications use aluminium base circuit boards, primarily because they enable higher levels of heat transfer. iPCB® is a professional manufacturer of high precision PCBs, which can mass produce 4-46 layers pcb boards, circuit boards, circuit boards, high-frequency boards, high-speed boards, HDI boards, pcb circuit boards, high-frequency and high-speed boards, double sided, multi-layer circuit boards, hdi boards, mixed voltage boards, high-frequency boards, rigid-flex boards, and so on.

The biggest difference between aluminium based circuit boards and conventional FR4 circuit boards lies in the heat dissipation. Compared with FR4 circuit boards with a thickness of 1.6mm and aluminium-based circuit boards, the thermal resistance of the former is 20-22℃, while that of the latter is much smaller by 1.0-2.0℃. Aluminium-based circuit board is a kind of metal-based copper-clad laminate with good thermal conductivity, which has good thermal conductivity, mechanical processing performance, gas and electric insulation performance.

1.Heat dissipation of aluminium based circuit boards

At present, many double-panel and multi-layer boards have high density and high power, which makes heat dissipation difficult.Conventional printed circuit board substrates such as FR4, CEM3 are hot bad conductors, interlayer insulation, heat dissipation does not go out. The local heat generation of electronic equipment is not excluded,which leads to the high temperature failure of electronic components,and the aluminium-based circuit board can solve this heat dissipation problem.

2.Dimensional stability of aluminium based circuit boards

Aluminium-based circuit boards are obviously much more dimensionally stable than printed circuit boards made of insulating materials.Aluminium based circuit boards and aluminium sandwich panels, heated from 30℃ to 140~150℃, the size change is 2.5~3.0%.

3.Thermal expansion of aluminium-based circuit boards

Thermal expansion and contraction is the common nature of material, and the coefficient of thermal expansion of different materials is different.Aluminium base circuit board can effectively solve the problem of heat dissipation, thus easing the thermal expansion and contraction of different substances on the components of the printed circuit board, improving the durability and reliability of the whole machine and electronic equipment, especially solving the problem of thermal expansion and contraction of the SMT SMD processing.

4.Other properties of aluminium-based circuit boards

Aluminium-based circuit board has a masking effect, replacing brittle ceramic substrate, rest assured that the use of surface mounting technology, reducing the real effective area of the printed circuit board, replacing components such as heat sinks, improving the thermal and physical properties of the product, reducing production costs and labour.

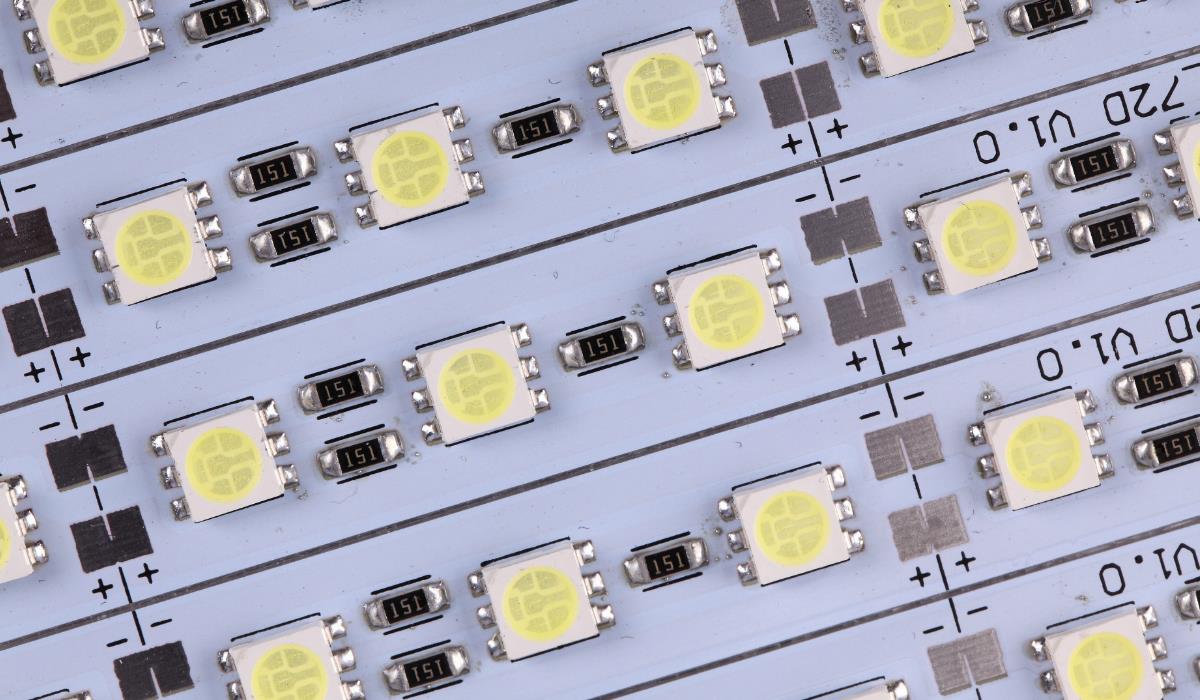

Aluminium-based LED circuit board

The advantages of aluminium base circuit boards are that the heat dissipation is significantly better than standard FR4 PCBs, the dielectric used is typically 5 to 10 times more thermally conductive than conventional epoxy glass, and the heat transfer index of one-tenth of the thickness is more efficient than that of conventional PCBs. What is the thermal conductivity of Aluminium PCBs? Aluminium PCB thermal conductivity refers to the heat dissipation performance parameter of the aluminium substrate, which is one of the three main criteria for measuring the performance of aluminium PCB. The thermal conductivity of Aluminium based circuit boards can be tested by testing instruments after the boards are pressed together, and a higher thermal conductivity is a sign of better performance of the Aluminium based circuit boards.

The thermal conductivity of aluminium-based circuit boards ranges from 1.0 to 2.5. Aluminium-based circuit boards are metal-based copper-clad boards with good heat dissipation capabilities, and usually consist of a single panel with a three-layer structure, namely, a circuit layer (copper foil), an insulating layer, and a metal base layer. For high-end applications, there are also double-sided boards designed with a structure of circuit layer, insulation layer, aluminium base, insulation layer and circuit layer. Very few applications are multi-layer boards, which can be formed by laminating a regular multi-layer board with an insulating layer and an aluminium base. The thermal conductivity of Aluminium based circuit boards is determined by the thickness of the copper foil and the insulating layer. The thickness of the copper foil is 25mu, 35mu, 70mu, and the insulating layer is PP glass fabric base (poor thermal conductivity), thermal conductive adhesive (good thermal conductivity), and ceramic powder (excellent thermal conductivity).

The size of the thermal conductivity of the aluminium-based circuit board is generally fixed, and will not change with the change of external factors, and the decision on the size of the thermal conductivity is mainly determined by the raw materials of the aluminium-based circuit board. If copper, silver and other high thermal conductivity materials are added, the thermal conductivity of the aluminium substrate material will certainly be higher. Thermal conductivity is a basic physical quantity, a fixed component of a material, and its thermal conductivity coefficient size has nothing to do with the thickness or area. Nowadays, the high thermal conductivity value is usually ceramic, copper, etc. However, because of the consideration of the question of cost, most of the market is now aluminium-based circuit boards, the corresponding thermal conductivity of aluminium substrates is a parameter of concern, the higher the thermal conductivity is one of the symbols of the better function.

1.Telecommunications industry:Telecommunications equipment usually uses PCBs to control its LED indicators and displays. In this industry, lightweight and durable PCBs are often advantageous, mainly due to the density of mechanical equipment in the industry. As aluminium-based PCBs tend to have better heat transfer characteristics than FR4 PCBs, aluminium-based PCBs can usually be found in telecom lighting applications.

2.Automotive industry: PCB LED displays are common in the automotive industry, especially in dashboard indicators, headlights, brake lights and premium panel displays. The industry is particularly fond of PCB LEDs because of their low manufacturing costs and durability, which can increase the value and life of the vehicle.

3.Computer technology industry: PCB-based LEDs are becoming more and more common in the computer technology industry and are commonly found in desktop and laptop computer displays and indicators. Due to the heat-sensitive nature of computer technology, aluminium-based PCBs are particularly suitable for LED lighting applications in computers.

4.Medical industry: Lighting tools in medical applications of great significance, especially in surgery and emergency applications, strong light can help improve the doctor's vision. In these applications, LED is often due to its low power and small size into the preferred lighting method. PCB is often used as the basis for these applications, especially the aluminium-based circuit board, compared with other types of PCB, its longer life, better heat transfer capacity. In this way, aluminium-based PCBs ensure long-lasting medical equipment that can be used repeatedly in various medical environments.

5.Residential and Storefront Applications: In addition to the uses listed above, PCB LEDs are becoming increasingly popular in homes and businesses in the form of signage and displays. Intelligent LED lighting is an inexpensive way for homeowners to efficiently illuminate their homes, while customisable LED displays can bring business to storefronts. iPCB ® is a professional manufacturer of high-precision PCB circuit boards, which can be manufactured in bulk quantities of aluminium-based circuit boards.