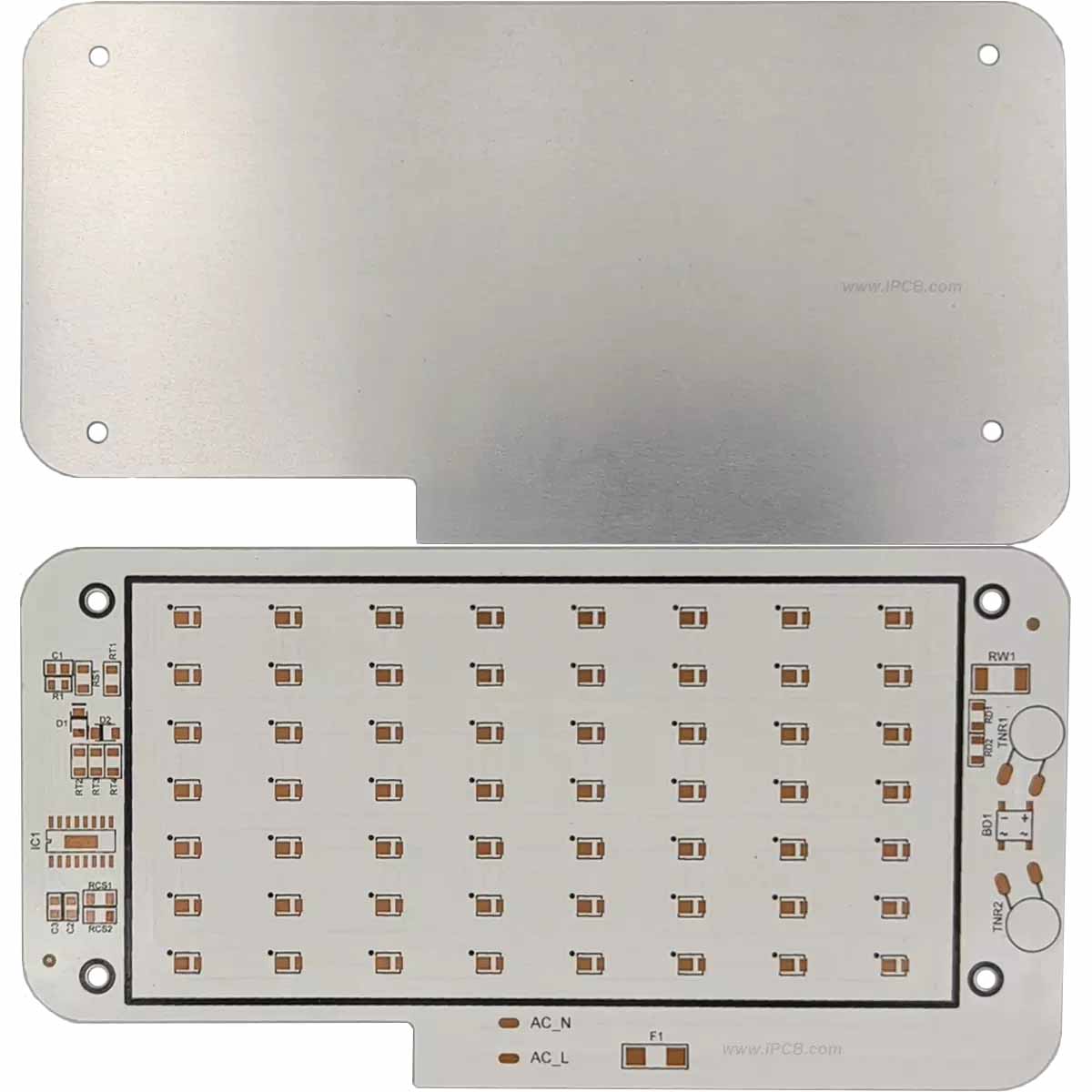

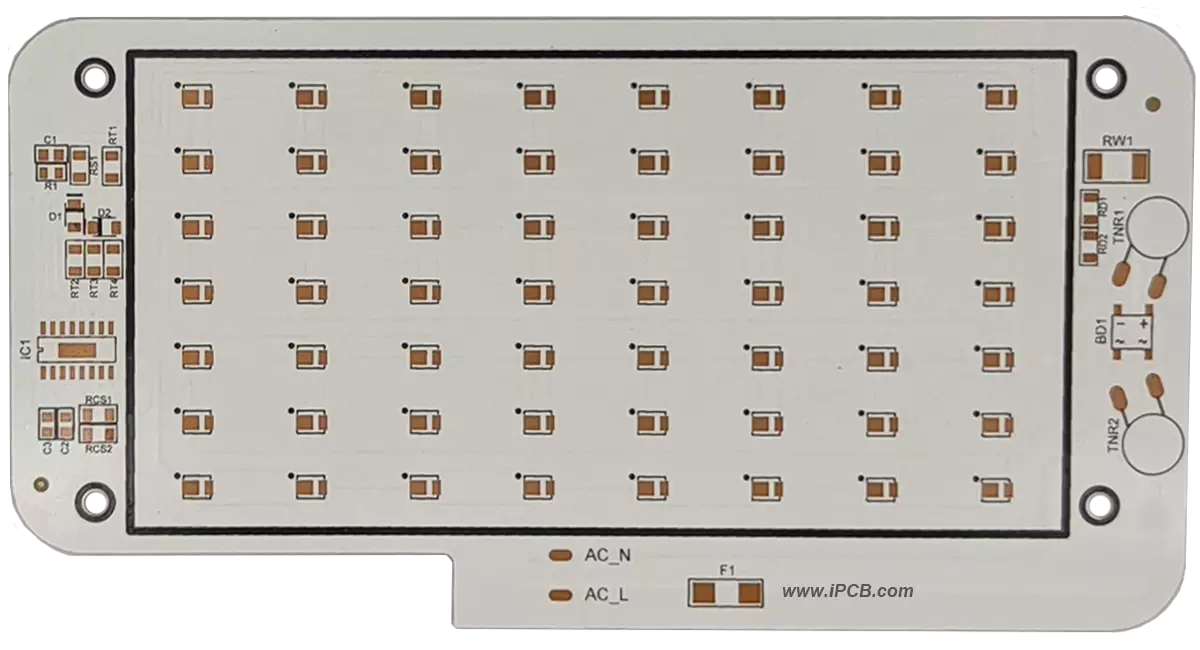

Product: Aluminum LED PCB

Material: aluminum substrate

Layer: 1

Color: White/Black

Finished thickness: 1.2mm

Copper thickness: 1oz

Surface treatment: OSP

Minimum line width: 8mil

Minimum spacing: 10mil

Thermal conductivity: 1-3W/mK

Application: LED Lamp

The aluminum based material in the middle of an aluminum PCB mainly serves the functions of connecting, conducting, insulating, and supporting, and has some interference with the transmission speed, energy loss, and characteristic impedance of signals in the circuit. The performance, quality, processability in production, manufacturing level, manufacturing cost, and long-term reliability and stability of aluminum PCBs are largely dependent on metal aluminum PCBs.

Aluminum PCB application

1. In the field of lighting, aluminum PCBs are widely used in high-power LEDs. Due to the excellent thermal conductivity of LED aluminum PCB, it can effectively dissipate heat, improve the luminous efficiency and lifespan of LED.

2. In the field of electronics, aluminum PCBs can be used in power electronic modules, power supplies, electronic transformers, and other devices. Its high thermal conductivity and excellent electrical performance make it an ideal choice for high-frequency electronic devices.

3. Automotive industry: Aluminum PCBs are widely used in automotive electronic control units (ECUs), automotive lighting systems, and battery management systems. It can meet the stable working requirements in high temperature environments and provide good heat dissipation performance.

4. In the field of solar energy, aluminum PCBs are commonly used in the manufacturing of solar panels. Its excellent thermal conductivity can effectively reduce the operating temperature of solar cells and improve conversion efficiency.

5. Industrial Control: Aluminum PCBs are also used in the production of various industrial control equipment, such as PLCs (Programmable Logic Controllers).

Manufacturing process of LED aluminum PCB

1. Substrate selection: The substrate of aluminum PCB is usually made of high-purity aluminum, which has good thermal conductivity and mechanical strength. The surface of the substrate is pre treated to improve the adhesion of the copper coating.

2. Preparation of Copper Coating: Coating a layer of copper foil on the surface of an aluminum substrate, which can be achieved through chemical copper plating or mechanical copper pressing methods. The thickness of copper foil depends on the application requirements, usually between 15 and 140 microns.

3. Graphicization: Using photolithography or laser direct writing techniques to create circuit patterns on a copper-clad layer. Photolithography technology involves covering photoresist and then forming the desired circuit pattern through exposure, development, and etching steps.

4. Surface treatment: In order to improve welding performance and prevent oxidation, the copper coating is usually subjected to chemical treatment or hot pressing treatment. Common surface treatment methods include tin spraying, silver spraying, or gold spraying.

5. Final processing: Depending on the specific application, aluminum PCBs may require final processing steps such as drilling, turning, milling, etc. to form the final circuit board structure.

Aluminum LED PCB

Aluminum PCB has a wide range of technological applications in fields such as lighting, electronics, automotive, and solar energy. The manufacturing process includes steps such as substrate selection, copper coating preparation, patterning, surface treatment, and final processing, ensuring the performance and reliability of the circuit board.

Aluminum PCB plays a key role in circuit applications that require efficient heat dissipation and high electrical heating performance, especially suitable for scenarios that require high heat dissipation, such as LED PCB.

Aluminum PCBs also have some drawbacks. Due to its metal substrate, the price of aluminum PCB is relatively high, generally much more expensive than FR4. In addition, due to the difficulty in bonding aluminum PCBs with the pins of general electronic devices, special treatments such as metallization are required, which increases manufacturing costs. In addition, the insulation layer of aluminum PCB also needs special treatment to ensure heat dissipation performance without affecting signal transmission quality.

In addition to price differences, there are also some differences between aluminum PCB and FR4 in terms of performance, application scope, and other aspects.

Aluminum PCB has better heat dissipation performance and can effectively dissipate the heat generated by the circuit board quickly. This makes aluminum PCB very suitable for high-power, high-density circuit design, such as LED lights, power modules, etc. Compared to it, FR4 has relatively weaker heat dissipation performance and is more suitable for low-power circuit design.

Aluminum PCB have greater current carrying capacity and are suitable for high-frequency, high current circuit applications. In high-power circuit design, current generates heat, and the high thermal conductivity and good heat dissipation performance of aluminum PCB can effectively dissipate heat, thereby ensuring the reliability and stability of the circuit. The current carrying capacity of FR4 is relatively small and not suitable for high-power, high-frequency circuit design.

The seismic performance of aluminum PCB is also better than FR4, which can better resist mechanical impact and vibration. Therefore, aluminum PCB has been widely used in electronic circuit design in fields such as automobiles and railways. At the same time, aluminum PCB also has good anti electromagnetic interference performance, which can effectively shield electromagnetic waves and reduce circuit interference.

Compared to FR4, aluminum PCB has better heat dissipation performance, current carrying capacity, seismic resistance, and electromagnetic interference resistance, making it suitable for high-power, high-density, and high-frequency circuit design. FR4 is suitable for general electronic circuit design, such as consumer electronics products such as mobile phones and laptops. The price of aluminum PCB is generally high, but for high demand circuit designs, choosing aluminum PCB is a very important step.

Aluminum PCB and FR4 are suitable for different types of circuit applications and have their own advantages and disadvantages. When selecting circuit board materials, it is necessary to weigh various factors and choose the most suitable material based on specific application scenarios and requirements.

If you need to customize aluminum LED PCB, you need to find a professional manufacturer. iPCB is a manufacturer specializing in circuit boards. Our products cover fields such as power supply, medical equipment, industrial control, communication, automotive electronics, security electronics, LED lamp and display screens, and consumer electronics.

Product: Aluminum LED PCB

Material: aluminum substrate

Layer: 1

Color: White/Black

Finished thickness: 1.2mm

Copper thickness: 1oz

Surface treatment: OSP

Minimum line width: 8mil

Minimum spacing: 10mil

Thermal conductivity: 1-3W/mK

Application: LED Lamp

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.