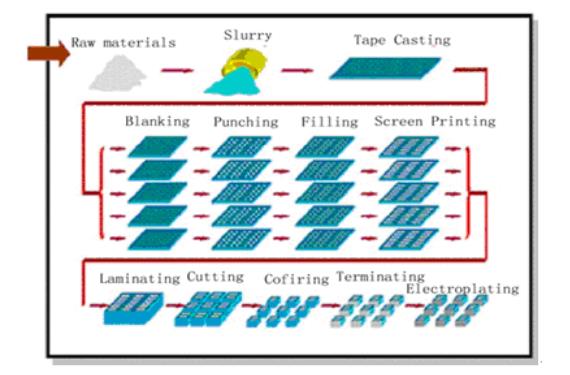

LTCC technology is a PCB technology developed by Hughes in 1982, which is a low-temperature sintered ceramic powder into a precise thickness and density of raw ceramic tape, in the raw ceramic tape using laser drilling, microvia grouting, precision conductor paste printing and other crafts to make the required circuit graphics, and a number of passive components (such as low capacitance capacitors, resistors, filters, impedance converters, couplers, etc.) are buried in the multi-layer ceramic Substrate, and then laminated together, the inner and outer electrodes can be used separately silver, copper, gold and other metals, sintered at 900 ℃, into a three-dimensional space without interference with each other, high-density circuit, but also into a three-dimensional circuit substrate passive components can be made, the surface can be pasted with ICs and active devices, into a passive/active integrated functional modules, can be further miniaturized and high-density circuits, especially suitable for high-frequency communication components. It is particularly suitable for high-frequency communication components.

In short, this technology can be utilized to successfully manufacture a wide range of LTCC technology products. There are many ways to integrate multiple passive components of different types and efficiencies into a single package, including LTCC low temperature co-fired ceramic technology, thin film technology, silicon wafer transistor technology, and multi-layer circuit board technology. LTCC technology is the mainstream technology for passive integration. LTCC integrated components include a variety of substrates to carry or embedded in a variety of active or passive components of the product, integrated components product items include parts (components), substrates (substrates) and modules (modules).

Technology Advantages of LTCC

1.Ceramic materials have excellent high-frequency, high-speed transmission and wide passband characteristics. According to the different ingredients, LTCC material dielectric constant can be changed in a wide range, with the use of high conductivity metal materials as the conductor data, is conducive to improving the quality of the circuit system factors, added flexibility in circuit design.

2. Can adapt to the requirements of high current and high temperature characteristics, and has a better thermal conductivity than ordinary PCB circuit board, greatly optimize the thermal design of electronic equipment, high reliability, can be used in harsh environments, extending its service life.

3. Can produce a high number of layers of circuit substrate, and can be buried in a number of passive components, eliminating the cost of packaging components, in a high number of layers of three-dimensional circuit substrate, the realization of passive and active integration, which is conducive to improving the assembly density of the circuit, and further reduce the volume and weight.

4. Good compatibility with other multilayer wiring technologies, such as the combination of LTCC and thin-film wiring technologies to achieve higher assembly density and better performance of hybrid multilayer substrates and hybrid multi-chip components.

5. Non-continuous production process facilitates quality inspection of each layer of wiring and interconnecting vias before the finished product is manufactured, which is conducive to improving the yield and quality of multilayer substrates, shortening the production cycle, and reducing costs.

6. Energy saving, material saving, green and environmental protection have become an unstoppable trend in the development of the component industry, LTCC also caters to this development demand, minimizing raw materials, waste and environmental pollution brought about by the production process.

Application Advantages of LTCC

1. Easy to realize more layers of wiring, improve assembly density.

2. Easy to embed components, increase assembly density, and realize multi-functionality;

3. Convenient for each layer of wiring and interconnecting holes for quality inspection before the substrate firing, which is conducive to improving the yield and quality of multi-layer substrates, shorten the production cycle and reduce costs.

4. Good high-frequency characteristics and high-speed transmission characteristics;

5. Easy to form a variety of structural cavities, thus realizing multi-functional microwave MCM with excellent performance;

6. Good compatibility with thin-film multilayer wiring technology, and the combination of the two can realize hybrid multilayer substrates and hybrid multi-chip components (MCM-C/D) with higher assembly density and better performance;

7. Easy to realize integrated structure of multilayer wiring and packaging, further reducing volume and weight, and improving reliability.

LTCC technical characteristics

1.Ceramic materials have excellent high frequency and high Q characteristics.

2. The use of high conductivity metal materials as the conductor data, which is conducive to improving the quality factor of the circuit system.

3. It can adapt to the requirements of high current and high temperature characteristics, and has better thermal conductivity than ordinary printed circuit boards.

4. Passive components can be buried in the multi-layer circuit board, which is conducive to improving the assembly density of the circuit. Fifth, with better temperature characteristics, such as smaller thermal expansion coefficients, smaller temperature coefficient of dielectric constant, can produce a very high number of layers of circuit board, can produce line widths of less than 50 μ m fine line structure. In addition, the non-continuous production process allows for inspection of raw substrates, which improves yield and reduces production costs.

5. One of the significant advantages of LTCC devices is their consistency and accuracy. This is entirely dependent on the stability of the data used and the precision of the process equipment.