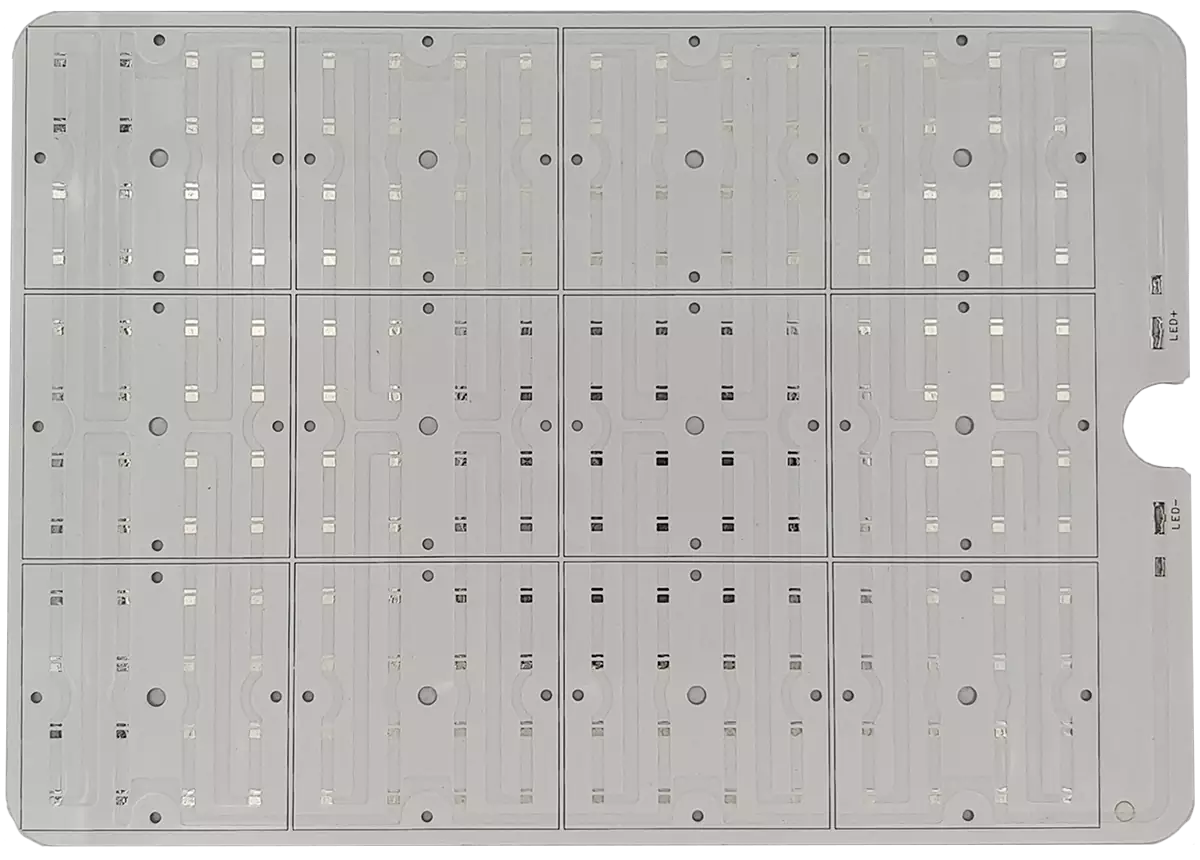

Product: Aluminum PCB

Material: Metal aluminum

Layer: 1

Color: White/Black

Finished thickness: 1.2mm

Copper thickness: 1oz

Surface treatment: OSP

Minimum line width: 8mil

Minimum spacing: 8mil

Thermal conductivity: 2W/mK

Application: Makeup lamp

Aluminum PCB is a metal PCB with good heat dissipation function. Generally, a single panel is composed of three layers: circuit layer (copper foil), insulation layer, and metal substrate. Commonly seen in LED aluminum PCB products. There are two sides, the white side is for soldering LED pins, and the other side presents the natural color of aluminum, usually coated with thermal conductive paste and in contact with the thermal conductive part.

PCB aluminum based copper-clad laminate is a metal circuit board composed of copper foil, thermal insulation layer, and metal substrate. Its structure is divided into three layers:

Circuit layer: equivalent to the copper-clad laminate of a regular PCB, with a copper foil thickness of 1oz to 10oz.

Insulation layer: The insulation layer is a layer of low thermal resistance thermal conductive insulation material. The core technology of aluminum based copper-clad laminates lies in the thickness range of 0.003 "to 0.006" inches, which has obtained UL certification.

Base layer: It is a metal substrate, usually aluminum or optional copper. Aluminum based copper-clad laminates and traditional epoxy glass cloth laminates, etc

PCB aluminum consists of circuit layer, thermal insulation layer, and metal substrate; The circuit layer (i.e. copper foil) is usually etched to form a printed circuit, connecting the various components of the component to each other. In general, the circuit layer requires a high current carrying capacity, so thicker copper foil should be used, with a thickness of generally 35 μ m~280 μ m.

The thermal insulation layer is the core technology of PCB aluminum PCB, which is generally composed of special polymers filled with special ceramics. It has low thermal resistance, excellent viscoelastic properties, and the ability to resist thermal aging, and can withstand mechanical and thermal stress. The thermal insulation layer of high-performance PCB aluminum PCBs such as IMS-H01, IMS-H02, and LED-0601 uses this technology, which gives them excellent thermal conductivity and high-strength electrical insulation performance.

The metal PCB is the supporting component of aluminum PCB, which requires high thermal conductivity. Generally, it is aluminum plate, but copper plate can also be used (copper plate can provide better thermal conductivity), suitable for conventional mechanical processing such as drilling, punching and cutting. PCB materials have unparalleled advantages compared to other materials. Suitable for surface mount SMT of power components. No need for a radiator, greatly reduced size, excellent heat dissipation effect, good insulation and mechanical properties.

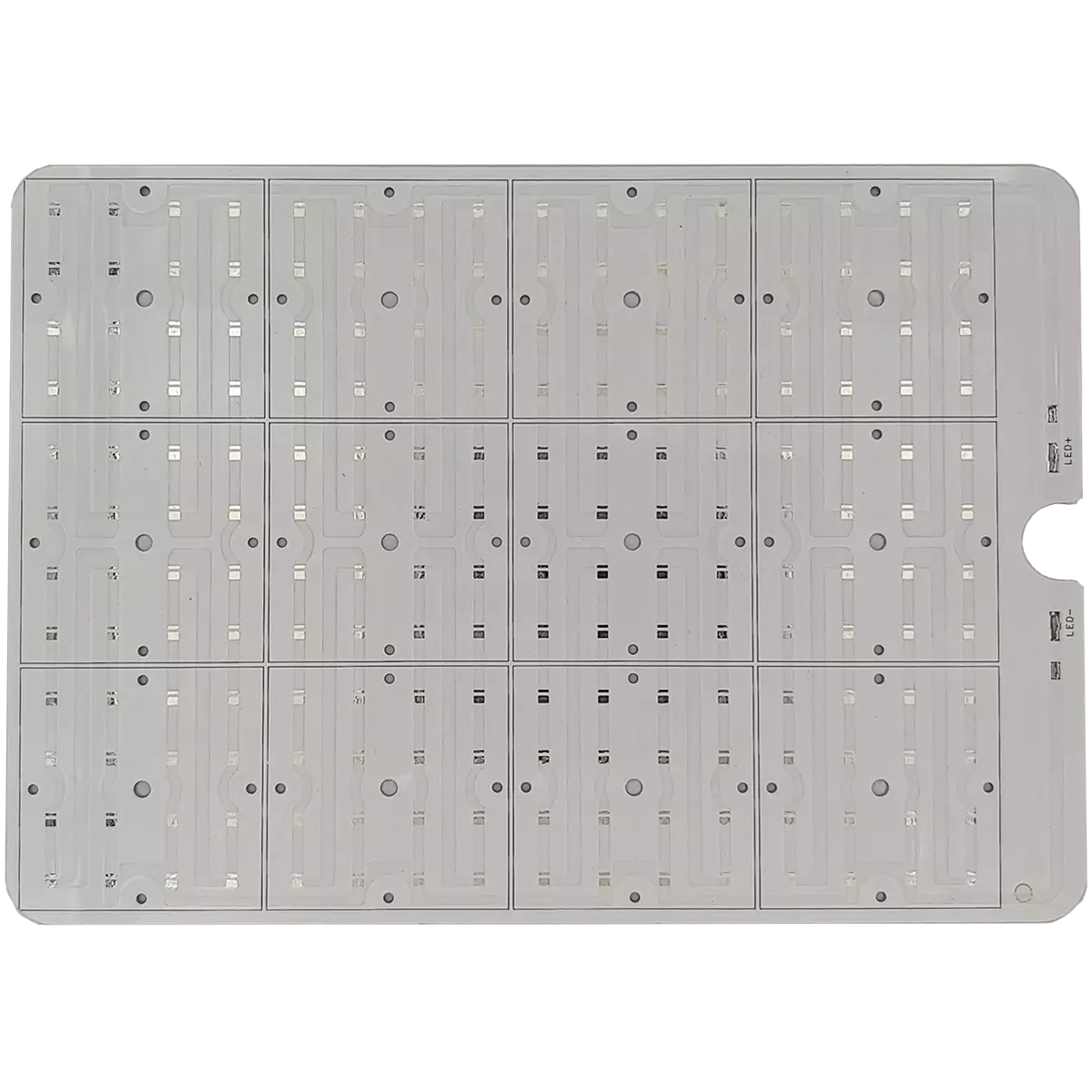

Makeup lamp aluminum PCB

Makeup lamp aluminum PCB is a type of aluminum PCB. The Makeup lamp is inserted with LED into the aluminum PCB, emits light when powered on, and conducts heat away from the aluminum PCB.

Product: Aluminum PCB

Material: Metal aluminum

Layer: 1

Color: White/Black

Finished thickness: 1.2mm

Copper thickness: 1oz

Surface treatment: OSP

Minimum line width: 8mil

Minimum spacing: 8mil

Thermal conductivity: 2W/mK

Application: Makeup lamp

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.