What is a mini breadboard?

Mini breadboards are designed and manufactured for solderless experiments of electronic circuits because there are many small sockets on the board. Since various electronic components can be inserted or unplugged at will as needed, soldering is eliminated, circuit assembly time is saved, and components can be reused, so they are very suitable for assembly, debugging and training of electronic circuits.

The name of the breadboard can be traced back to the era of vacuum tube circuits. At that time, most of the circuit components were large in size. People usually fixed them on a piece of bread-cutting wood board for connection by screws and nails. Later, the circuit components became smaller and smaller, but the name of the breadboard was used.

What is the use of breadboards?

Modern electronic breadboards usually do not require soldered components. Therefore, their connections are temporary, which means that users can quickly and easily insert and remove them for operation when revisions or corrections are needed.

Breadboards are most commonly used in prototyping applications. Solderless breadboards that do not require soldering components to the PCB surface make it easier and faster to move and exchange components until the desired effect is achieved. This is ideal for experimental design and rigorous testing of circuits. The hot-swappable component capabilities of breadboards make them very convenient devices during the prototype stage of circuit design and development.

Using breadboards is not only more economical in terms of time and money, but it also makes diagnostic and debugging work easier.

Solderless mini breadboards are ideal for technical analysis applications. By routing circuits on breadboards, electronic engineers can quickly replicate real PCBs that exist in existing products or systems. This is particularly useful in helping to determine where a failure point or fault may occur in a circuit without wasting time and money making incremental or experimental adjustments to a fully soldered circuit board. In a large and complex circuit, a misplaced lead can cause the entire system to behave abnormally (or stop working altogether). Being able to see exactly where each component pin is without guessing or having to slow down work due to incorrect soldering greatly improves efficiency.

Construction Features

The entire board is made of thermosetting phenolic resin, with a metal strip on the bottom of the board. The corresponding holes on the board allow the components to contact the metal strip when inserted into the holes, thereby achieving the purpose of conductivity. Generally, every 5 holes are connected with a metal strip. There is generally a groove in the center of the board, which is designed for integrated circuit and chip testing. There are two rows of vertical jacks on both sides of the board, also in groups of 5. These two groups of jacks are used to provide power to the components on the board.

The motherboard uses a fiberglass board with a copper foil conductive layer, which is used to fix the solderless breadboard and lead out the power terminal.

Classification of mini breadboards

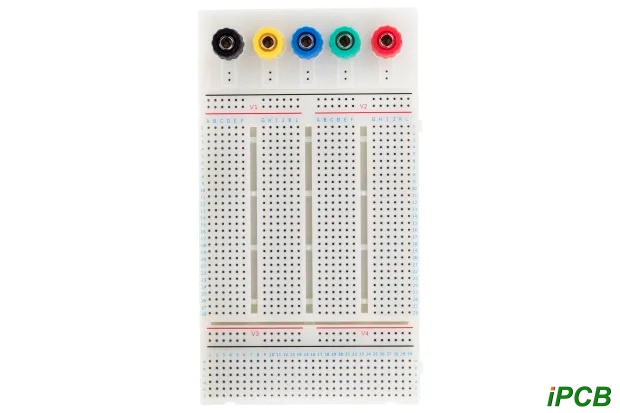

Solderless breadboard

A solderless breadboard is a motherboard without a base, without a soldered power socket lead out, but can expand a single breadboard. It should be powered on when used. Connect the two poles of the power supply to the jacks on both sides of the breadboard, and then you can plug in the components for the experiment (disconnect the power supply during the process of plugging in the components). When there are more than 5 components or a group of jacks cannot be plugged in, you need to use breadboard cables to connect multiple groups of jacks.

The advantages of solderless breadboards are small size and easy to carry, but the disadvantages are that they are relatively simple, inconvenient to connect the power supply, and small area. It is not suitable for large-scale circuit experiments. If you want to use it for large-scale circuit experiments, you need to fix multiple breadboards on a large wooden board with screws and then connect them with wires.

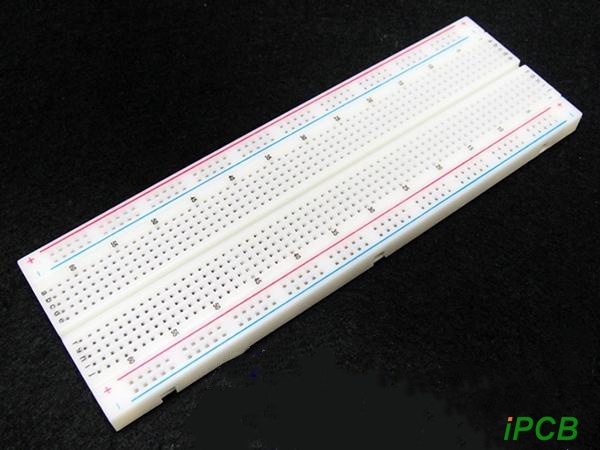

Single breadboard

A single breadboard is a breadboard with a motherboard as the base, and the power supply is connected with a dedicated terminal, and some can even perform high-voltage experiments with ground terminals. This board is more convenient to use. Just connect the power supply directly to the terminal, and then insert the components for experiment (disconnect the power supply during the component insertion process). When there are more than 5 components or a group of jacks cannot be inserted, you need to use breadboard cables to connect multiple groups of jacks.

The advantages of a single breadboard are that it is small in size, easy to carry, and can be easily turned on and off, but the disadvantage is that it is small in area and is not suitable for large-scale circuit experiments.

The mini breadboard circuit experiment makes engineers' innovative thinking blossom.

In the vast world of electronic engineering, the mini breadboard is like a small world full of magic. It looks small, but it carries countless seeds of creativity. Engineers gathered in front of this small breadboard, with a fiery light flashing in their eyes. The electronic components in their hands are like thousands of troops waiting to be commanded. With their skillful hands, resistors, capacitors, and chips are carefully placed in the various sockets of the breadboard, and wires act like flexible bonds, cleverly connecting these components together.