In the realm of electronics, one crucial component that plays a foundational role in ensuring the functionality of motherboards is the soldering process. A motherboard, often considered the heart of any computing device, relies heavily on high-quality soldering to connect various electronic components such as capacitors, resistors, transistors, and integrated circuits. The process of soldering not only ensures these components are securely affixed but also guarantees the transmission of electrical signals. This article will explore the significance of solder in motherboard manufacturing, the types of solder used, the soldering techniques, and the common challenges faced in this process.

The Importance of Solder in Motherboard Assembly

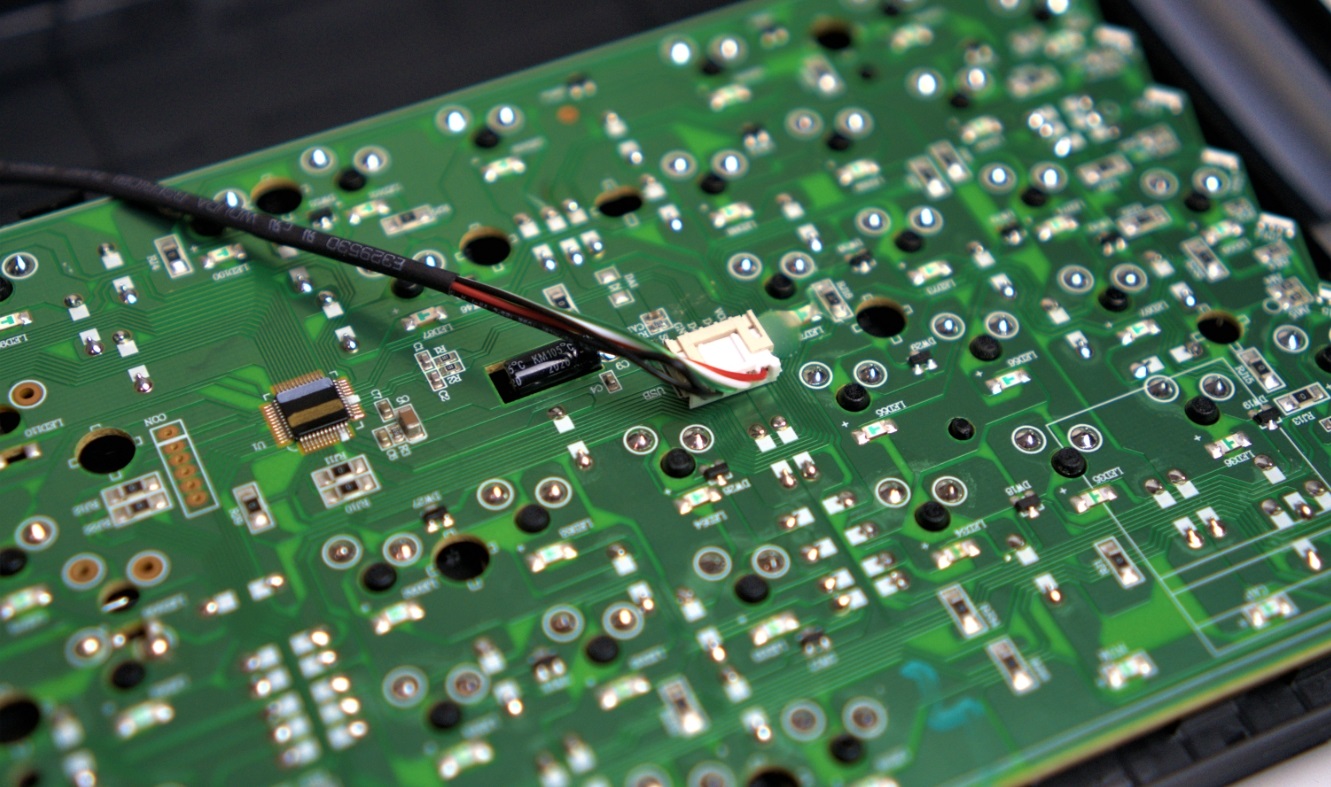

A motherboard is the central printed circuit board (PCB) that acts as the main communication hub for all the components of a computer. For a motherboard to function seamlessly, each of its electronic components must be properly connected to the PCB, forming a reliable electrical circuit. This is where solder comes in.

Solder is a fusible metal alloy used to join different metal surfaces by melting the solder and allowing it to cool, forming a solid connection. In motherboard assembly, solder creates both mechanical and electrical bonds between components and the PCB. Without a reliable solder joint, the motherboard would face issues like intermittent connectivity, poor signal transmission, or complete malfunction.

In the early days of electronics, lead-based solder was commonly used due to its ease of use, low melting point, and strong bond. However, with environmental concerns and the RoHS (Restriction of Hazardous Substances) directive coming into effect, lead-free solders have become the standard in most manufacturing processes.

Types of Solder Used in Motherboard Manufacturing

Solder comes in various compositions and types, each with its unique properties suitable for specific applications. In motherboard manufacturing, two primary types of solder are typically used:

1. Lead-Based Solder: Lead-based solder was the industry standard for many years, consisting of a mix of tin (Sn) and lead (Pb). The most common alloy ratio was 63% tin and 37% lead (Sn63Pb37), which offered a low melting point of around 183°C. This low melting point made it easier to work with and required less energy for soldering. Lead-based solder also had excellent wettability, ensuring it easily flowed over metal surfaces, creating strong and reliable joints.

However, the use of lead in electronics has been significantly reduced due to environmental and health concerns. Lead is a toxic material that poses risks to both workers and the environment, prompting the transition to lead-free alternatives.

2. Lead-Free Solder: As part of the RoHS directive, most modern motherboards are now manufactured using lead-free solder. The most common lead-free solder alloys are based on tin, silver, and copper (SAC). A typical formulation is SAC305, which contains 96.5% tin, 3% silver, and 0.5% copper. Lead-free solder has a higher melting point than lead-based solder, typically around 217°C to 220°C.

While lead-free solder is more environmentally friendly, it presents some challenges in the manufacturing process. It requires higher soldering temperatures, which can stress components and the PCB. Additionally, lead-free solder has a higher tendency to form voids and cracks in the joints over time, which could affect the long-term reliability of the motherboard.

Soldering Techniques for Motherboard Assembly

Soldering is a delicate process that requires precision and expertise. There are several techniques used to solder components onto motherboards, each with specific advantages and challenges:

1. Hand Soldering: Hand soldering is often used for small-scale repairs or for adding individual components to a motherboard. A soldering iron is used to manually melt the solder, allowing it to flow and create a connection between the component's lead and the PCB. While hand soldering is a versatile method, it requires skill and precision to avoid overheating the components or creating weak joints.

2. Wave Soldering: Wave soldering is a high-volume process commonly used in motherboard production. During this process, the entire PCB passes over a wave of molten solder. As the board moves through, the solder adheres to the exposed metal areas, forming connections between the component leads and the PCB. Wave soldering is efficient for through-hole components, but it may not be ideal for surface-mount components, as it can result in solder bridges or other defects.

3. Reflow Soldering: Reflow soldering is the most widely used technique in modern motherboard manufacturing, particularly for surface-mount components. In this method, a solder paste (a mixture of powdered solder and flux) is applied to the PCB's pads before the components are placed on top. The entire assembly is then heated in a reflow oven, melting the solder and forming solid connections. Reflow soldering allows for precise control of the heating process, reducing the risk of thermal damage to components.

Reflow soldering is particularly suited for high-density motherboards with fine-pitch components, ensuring reliable connections in a compact space.

Challenges in Motherboard Soldering

Despite advancements in soldering technology, motherboard soldering is not without challenges. Some of the common issues faced during the soldering process include:

1. Solder Bridging: Solder bridging occurs when excess solder forms an unintended connection between two adjacent component leads. This creates a short circuit, leading to malfunctioning components or the entire motherboard. Bridging is more common when working with fine-pitch components, and careful control of the soldering process is required to avoid this issue.

2. Cold Joints: A cold solder joint occurs when the solder does not fully melt or adhere to the component lead and the PCB. This results in weak connections that can cause intermittent failures or complete disconnection. Cold joints are often caused by insufficient heat during the soldering process, poor flux application, or contamination of the soldering surface.

3. Solder Voids: Voids are air pockets trapped within the solder joint, which weaken the mechanical and electrical connection. In motherboard manufacturing, voids can occur during reflow soldering if the solder paste is not applied uniformly or if the heating profile is not optimized. Voids can compromise the reliability of the motherboard, especially in high-frequency applications.

4. Component Damage: The high temperatures required for lead-free soldering can potentially damage sensitive components or the PCB itself. Overheating can cause delamination of the PCB layers, warping, or damage to integrated circuits. Manufacturers must carefully monitor and control the soldering temperature to prevent these issues.

The Future of Soldering in Motherboards

As technology evolves, so do the demands placed on motherboards and their soldering processes. The rise of smaller, more compact devices has led to the development of miniaturized components, requiring even more precise soldering techniques. Additionally, the push for faster, more efficient manufacturing processes has spurred advancements in automated soldering systems, reducing human error and increasing production speed.

One potential future direction for soldering technology is the use of advanced alloys that offer the benefits of lead-based solder (such as a lower melting point and stronger joints) without the environmental drawbacks. Researchers are also exploring alternative joining methods, such as conductive adhesives, which could potentially eliminate the need for traditional solder in some applications.

In conclusion, soldering is a critical process in motherboard manufacturing, ensuring the reliable connection of components and the long-term performance of the board. While lead-based solders have been largely replaced by lead-free alternatives, the challenges of higher soldering temperatures and potential defects remain significant. By continuously improving soldering techniques and materials, manufacturers can meet the demands of modern electronics and ensure the durability and reliability of their motherboards.