Against the backdrop of the rapid development of high-speed and high-frequency electronic products, multilayer Rogers PCB has become a key basic component in cutting-edge applications such as 5G communications, millimeter-wave radar, and aerospace due to its excellent electrical performance and high reliability.

Rogers PCB is a high-frequency board material produced by Rogers Corporation. It is different from the traditional PCB board-epoxy resin (FR4). It has no glass fiber in the middle and uses ceramic powder as a high-frequency material. Rogers has superior dielectric constant DK and temperature stability. Its dielectric constant thermal expansion coefficient is very consistent with copper foil, which can be used to improve the shortcomings of polytetrafluoroethylene-based boards. It is very suitable for high-speed electronic design, commercial microwave and RF applications.

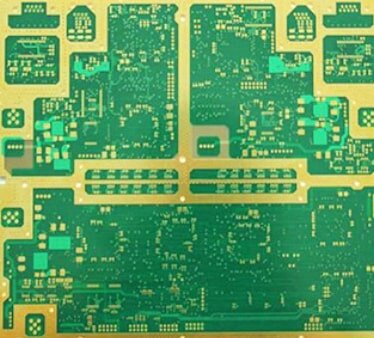

Structural features of multilayer Rogers PCB

Multilayer Rogers PCB is a composite board made of Rogers material in more than two layers. Rogers material is also mixed with traditional FR-4 in some laminated structures. Common structures include 4 layers, 6 layers, 8 layers, and even more than 12 layers, usually containing signal layers, ground layers, power layers, etc., to meet the electrical requirements of complex systems.

Multilayer Rogers PCB

Key points for multilayer Rogers PCB structure design:

1. Dielectric constant matching

If different Rogers models or mixed FR-4 are used between different layers, it is necessary to ensure that the dielectric constant is consistent or reasonably matched to avoid impedance discontinuity.

2. Lamination process control

When laminating multi-layer Rogers PCBs, special attention should be paid to temperature and pressure control to prevent interlayer separation or uneven dielectric flow.

3. High impedance control accuracy

It is mostly used in RF microstrip and stripline structures, and the trace width, dielectric thickness, and copper thickness must be strictly controlled.

4. Complex mixed pressure process

Some structures use the "Rogers + FR-4" mixed pressure method, which is lower in cost, but more challenging in process and requires strict experience.

Introduction to Rogers board models

1. RO4000® series

The RO4000 series board is a high-performance circuit board material from Rogers Corporation, especially suitable for high-frequency applications. These boards are often used in wireless infrastructure, satellite communications, and radar systems.

RO4003C™: Has a higher dielectric constant for applications that require larger capacitance values.

RO4350B™: Offers extremely low dielectric constant and dissipation factor, suitable for high-speed signal transmission.

2. ROG™ Ceramic-Based Boards

ROG series boards are recognized by the market for their high thermal conductivity and excellent electrical insulation properties, suitable for high-power amplifiers and RF power devices.

3. 3200™ Series

3200 series boards offer balanced electrical and mechanical properties for a wide range of electronic applications, including multi-layer panels and rigid circuit boards.

3210™: Has a medium dielectric constant and dissipation factor, suitable for general electronic and electrical applications.

4. RO300™ Series

RO300 series boards are known for their flexibility and durability, suitable for flexible circuit boards and wearable devices.

Multilayer Rogers PCBs have become an indispensable key component in the field of high-end electronics due to their excellent high-frequency performance, stable structural characteristics, and reliable manufacturing foundation. Although its cost is higher than that of traditional PCB, its value far exceeds its price in high-performance electronic systems. With the development of high-frequency communication and intelligent systems, the technical evolution and industrial application prospects of multi-layer Rogers PCB will be broader.

For electronic engineers, in-depth understanding of the characteristics of Rogers materials and their application in multi-layer board structures will help to better carry out circuit design, material selection and performance optimization; for manufacturing companies, mastering the core process technology of multilayer Rogers PCB means taking the lead in the high-end PCB market.