With the development of smart phones, tablet PCs, wearable devices and other products in the direction of miniaturisation and multifunctionality, the technology of high-density interconnecting circuit boards continues to improve. The distance between the conductor and insulation layers and the thickness of the layers are constantly decreasing, so that the number of layers of the board can be increased to accommodate more components without increasing the size, weight and volume of the board. In addition, as wireless data transmission bandwidths and processing speeds increase, the electrical performance of the board becomes critical.

Just as the IC industry has encountered barriers to performance scaling and compliance with Moore's Law, the board industry faces challenges in process capability and data performance to continually improve interconnect density and power performance. Even when circuit boards are designed with Arbitrary Layer Vertical Interconnect High Density (ALVHDI), there are still limitations in terms of performance scaling and enhancement, and with that comes increased manufacturing costs and price/performance issues.

The circuit board industry is facing the challenge of adding more layers and reducing thickness. As the thickness of the insulation layer drops below the critical value of 50 μm, the dimensional stability and electrical performance of the boards, especially the signal impedance and insulation resistance, decrease. At the same time, the density of signal alignments is increasing, with alignment widths of less than 40 µm. Such traces are difficult to perform using conventional subtractive methods. Although additive technology can enable the production of finer circuits, it suffers from high cost and small production scale.

The landing of 5G is an important national policy in 2019, which will drive the entire upstream and downstream industry chain.5G technology will drive the Internet of Things,cloud computing, big data, artificial intelligence and other related areas of fissile development, enabling vertical industries and deep integration. The formation of the 5G ecosystem will provide strong impetus for national competitiveness,social transformation and industrial upgrading.

5G is gradually coming to us from concepts and experimental products. We are ready to work together to create a better 5G era,to accept our many worries and challenges,and to create a better future with happiness for all.

Due to the advantages of low cost and easy maintenance of carbon direct plating system,electronic manufacturers choose it to replace the chemical copper plating process.Today, there are hundreds of high-volume Carbon Series direct plating production lines around the world. These systems are popular because they use less water,produce less wastewater,take up less space and consume less energy.In addition, these systems do not require precious metals such as palladium for activation, which can lead to significant savings in operating costs.

In the latest generation of smartphone technology,high-density interconnect (HDI) technology is moving towards finer line widths and spacing,which requires the use of ultra-thin copper foils as the starting point for the entire production process.This ultra-thin copper foil technology requires precise control of the etching accuracy during the formation of the copper interconnect.Direct plating processes,such as the latest generation of Black Hole Technology, have begun advanced semi-additive production on 3 micron copper foils.

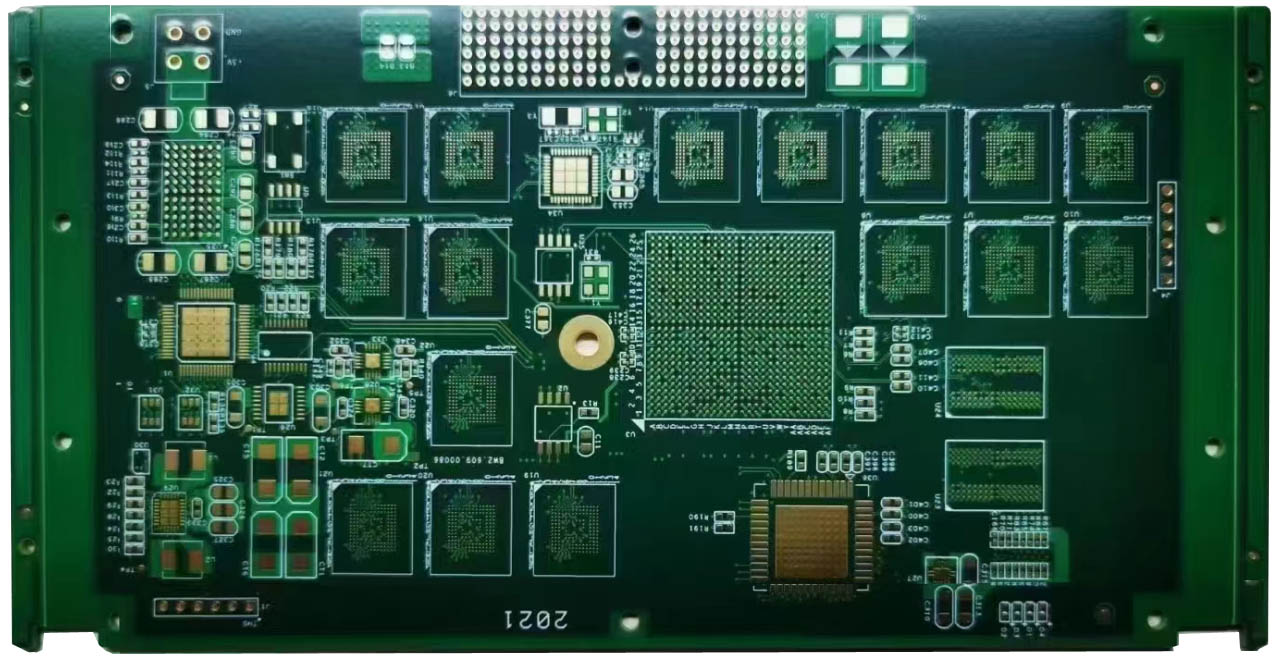

hdi pcb

The direct plating process has evolved over the past few years in response to the needs of circuit board design. Driven by miniaturisation, from leaded components to surface mounted components, the board design has evolved to accommodate micro components with more pins, which results in new board layers, thicker boards and smaller through-hole diameters. To meet the challenge of high aspect ratios, production line specifications should address improvements in microvia solution transfer and exchange, such as the use of ultrasonics to rapidly wet the vias and remove air bubbles, and to improve the ability of air knives and dryers to efficiently dry small vias on thicker boards.

From there,board designers moved on to the next stage: blind hole starvation, pin counts, and ball grid densities that outstripped the board surface available for drilling and routing. As the 1.27mm to 1.00mm grid of Ball Grid Array Packages (BGAs) shifted to the 0.80mm to 0.64mm grid of Chip-Scale Packages (CSPs), micro-blind vias became a challenge for designers to deal with in HDI technology.

In 1997,feature phones began to use 1+N+1 HDI circuit board design for mass production. This is a design with micro-blind vias in the stacked layers on the core. As mobile phone sales grew, pre-etched windows and CO2 lasers, UV, UV-YAG lasers, and a combination of UV-CO2 lasers were used to form the micro-blind vias. Microblind vias allow designers to route wires underneath the blind vias, which allows for the redistribution of more pin grids without adding new layers. HDI is now widely used in three platforms: miniaturisation, high-end packaging and high-performance electronics. Miniaturisation in mobile phone design is the most productive application today.

With the rapid development of electronic technology, only by recognising the development trend of circuit board technology, circuit board manufacturers can actively develop innovative production technology and find a way out in the highly competitive circuit board industry. As the world's largest producer of circuit boards, Shenzhen circuit board manufacturers production and processing capacity will become a key part of the development of the electronics industry. Circuit board manufacturers must always maintain a sense of development.

The following are some of the views on the development of circuit board production and processing technology:

1. Development of component embedded technology

Component embedded technology is a pcb board function of the integrated circuit of the great changes.Has begun to form semiconductor devices in the inner layer of the circuit board (known as active components), electronic components (known as passive components) or passive components.Production, but to develop circuit board manufacturers must first address the analogous design methods,production technology and inspection quality, reliability assurance is also a top priority. Circuit board manufacturers must increase the design, equipment, testing, simulation and other systems of resource investment in order to maintain a strong vitality.

2.HDI circuit board technology is still the mainstream direction of development

HDI circuit board technology to promote the development of mobile phones, driving the development of LSI and CSP chips (packaging) information processing and control of the basic frequency function, as well as the development of circuit board packaging template substrate. It has also contributed to the development of circuit boards. As a result, circuit board manufacturers must innovate along the path of HDI circuit boards. Processing technology for circuit board production. Since HDI embodies the most advanced technology in contemporary circuit boards, it brings fine lines and tiny apertures to circuit boards. HDI's multilayer boards are used in end-use electronics - mobile phones (cell phones) are an example of HDI's cutting-edge development technology. In mobile phones, micro lines (50 μ m to 75 μ m/50 μ m to 75 μ m, line width/spacing) of circuit board motherboards have become the mainstream. In addition, the conductive layer and board thickness have become thinner.

For the future business layout, 5G, biometrics, or pressure sensing,sensors,autonomous driving, or cloud storage, computing, base stations, etc. may be applied to HDI circuit boards.