Many electronic engineers in the product design,PCBA prototyping only a small number of orders, generally about 10 pieces of samples, such a small number of PCBA sampling orders if you take into account the processing costs,you can use the PCBA hand-paste processing.

In the hand sticker processing production, IC splicing is more difficult,after all,IC is generally a higher number of pins of IC,which requires our sticker processing staff to carefully and patiently to deal with and strictly in accordance with the processing requirements to operate in order to get and machine sticker quality equivalent products. There are a lot of noteworthy things about hand soldering of ICs,such as the high degree of internal integration, which can be easily damaged by overheating, and so on.

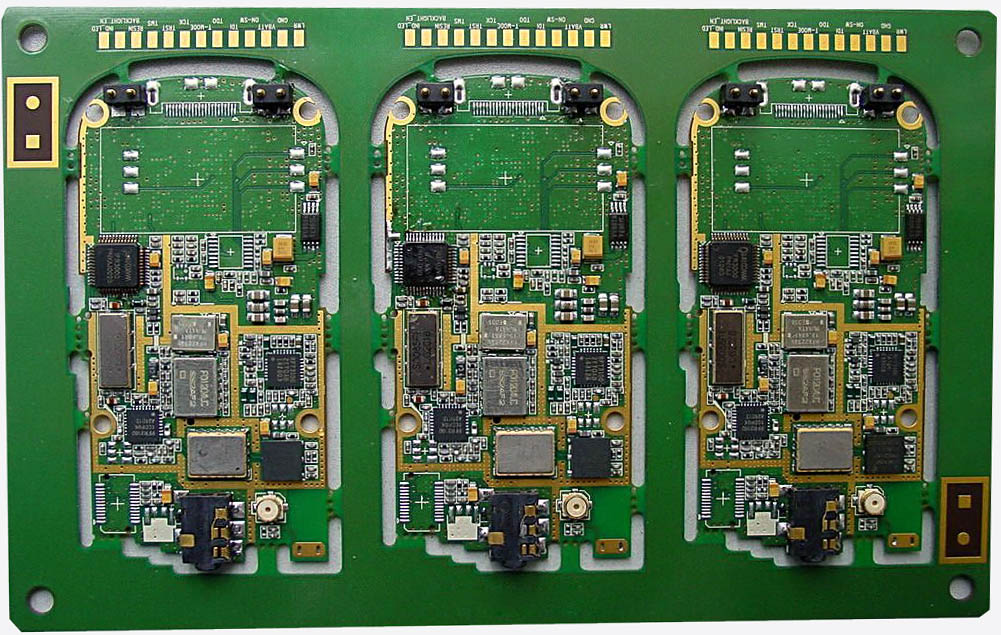

PCBA prototyping

Steps of IC chip SMD soldering

SMD welding is an indispensable part of the PCBA prototyping process,if there is a mistake in this process, it may directly affect or discard the circuit boards of SMD processing, and this soldering should be familiar with the correct welding methods and understand the relevant notes to avoid problems.

1.Before soldering, apply flux on the solder and treat it with solder once so that the soldered board will not be poorly plated or oxidised, and wafers generally do not need to be treated.

2.Use tweezers to carefully place the PQFP chip on the PCB. Be careful not to damage the pins. Align the chip with the pad so that the chip is in the correct orientation.Control the temperature of the soldering iron at 300 degrees Celsius, put a small amount of solder on the end of the soldering iron,use the tool to press down on the positioned wafer,put a small amount of solder on the two diagonal pins,and still press down on the wafer to solder the two diagonal pins so that the wafer is fixed and does not move.After soldering the diagonal pins, reconfirm the alignment of the wafers.If necessary,it can be adjusted or removed and rearranged on the PCB board.

3.When you start to solder all the pins,you should insert solder into the end of the soldering iron and smear all the pins with solder to keep them wet.Touch each pin end of the wafer with the soldering iron until you see the solder flow into the pins. When soldering,the end of the soldering iron should be parallel to the soldering pins to prevent excessive overlap of the soldering tin.

4.After soldering all pins,use solder on all pins and clean the solder notes.Siphon unnecessary solder notes from where they are needed to eliminate short circuits and overlaps.Finally,use tweezers to check for virtual soldering.After the inspection is complete,apply the solder to the circuit board.SMD resistive components are relatively easy to solder.You can start by annotating the solder joints,placing one end of the component,clamping the component with tweezers, soldering one end,and then checking to make sure it's upright.If it's already in the right place,re-solder the other end.It takes a lot of practice to master soldering techniques.

Common Precautions for PCBA prototyping and Processing IC SMD

1.IC soldering time should be as short as possible,generally no more than 3s.

2.The soldering iron used is good, is a constant temperature 230 degrees soldering iron.

3.PCBA prototyping machine workstation should be good anti-static treatment.

4.Choose a narrower tip of the soldering iron head, soldering will not touch the neighbouring endpoints.

5.Do not remove the CMOS circuit before soldering during PCBA prototyping.