PCBs (printed circuit boards), as the core foundation of electronic systems, play a vital role. In the entire electronics manufacturing process, PCB box build assembly services are a critical step connecting "design" to "finished product."

iPCB, as a reliable, fast, and professional PCB and PCBA manufacturer, not only provides high-precision PCB and SMT placement services, but also has extensive experience in PCB box build assembly services, committed to providing customers with truly efficient, one-stop electronics manufacturing solutions.

pcb box build assembly services

What are PCB box build assembly services?

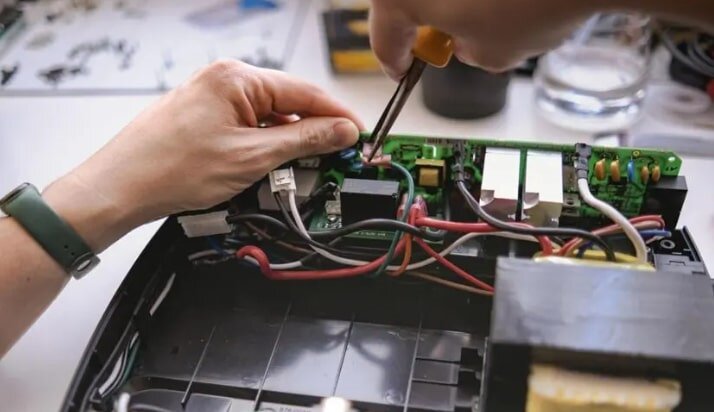

PCB box build assembly services, commonly referred to as "Box Build Assembly," refers to the process of assembling circuit boards, structural components, cables, display modules, connectors, batteries, and housings into a complete end product after the PCB and PCBA are completed.

This service not only includes electrical connections and structural installation, but also involves a series of integration tasks such as functional testing, software loading, labeling, and packaging for shipment. It is the final, critical step in the electronics manufacturing process, directly impacting the final product quality and delivery status.

Standard Process for PCB Box Assembly

Box assembly service is not simply "putting the PCBA into the box"; it is a systematic, standardized process that typically includes the following steps:

1. Project Assessment and Document Review

Review of the assembly BOM, structural drawings, and 3D files provided by the customer

Clearly define the assembly method, bill of materials, and electrical connection logic

Determine the test plan and software programming requirements

2. PCB Manufacturing and PCBA Processing

Prototype or mass production of circuit boards (such as multilayer boards, HDI boards, rigid-flex boards, etc.) based on the design

SMT placement and plug-in soldering

Electrical testing (ICT, FCT), optical inspection (AOI), X-ray inspection, etc.

3. Incoming Material Inspection and Structural Preparation

Incoming material inspection of structural components, cables, batteries, displays, connectors, etc.

Sorting, cleaning, and pre-assembly according to customer standards

4. Assembly

Installation of the PCBA into the enclosure

Complete wiring and connection of power cables, signal cables, and ribbon cables

Installation of structural components such as the display, buttons, USB port, battery, and cooling system

Secure screws, apply glue, or snap fasteners to ensure mechanical strength and structural sealing

pcb box build assembly services

5. Functional testing and software programming

Power-on testing, port function testing, signal transmission testing

Software programming, serial number binding, system debugging

Optional reliability testing such as high-temperature aging testing and drop testing

6. Inspection, Packaging, and Shipping

Inspect the housing for scratches, dust, and improper installation. Anti-static bags, foam packaging, blister packing, color boxes, or neutral packaging are available. Instructions, certificates of conformity, and instruction cards are available. Full case packaging, palletizing, and logistics shipping are available.

With increasingly complex products and shortened delivery cycles, customers need a partner that can provide systematic manufacturing solutions.

iPCB, with its core philosophy of "Reliable, Rapid, and Professional," is committed to becoming your trusted provider of pcb box build assembly services. Whether you're a startup or a large enterprise with a complex supply chain, iPCB can provide tailored, efficient, and high-quality pcb box build assembly services, taking your product from PCB to finished product in one step.