Baking pcb can eliminate the internal stress of the PCB board, that is, stabilise the size of the PCB. The most obvious advantage is that the PCB baking can make the pad in the moisture drying, strengthen the welding effect, reduce the virtual welding, repair rate, and so on. However, the baking board will make the PCB board colour to produce a change, and affect the appearance.

Partners engaged in the PCB industry know that the copper-laying board in the insulation material on a sheet of copper foil,and then baked dry.If you look closely,you will see that there will be shrinkage during the drying process,and stress will be generated in all directions,which is the source of stress.

The purpose of baking the board before drilling is actually to remove moisture.Baking PCB before drilling is to remove water from the board and reduce internal stress. After pressing, there is also printed soldering,including characters and so on,all need to bake the board. There is also the process of baking and pressing the board before shipment and packaging, also for the purpose of removing moisture, after baking the board in the warpage of the board has a relatively large improvement.

Usually bake the board in general 100-120 ° C,bake the board about 2H,pay attention not to bake the board for too long.If exposed to the air within a day of the need to play on the line to finish,otherwise easy to oxidation, of course, this is not absolute, but also depends on the PCB supplier's ability to produce,some of the PCB chemical gold craftsmanship relative to the preservation of a longer period of time.

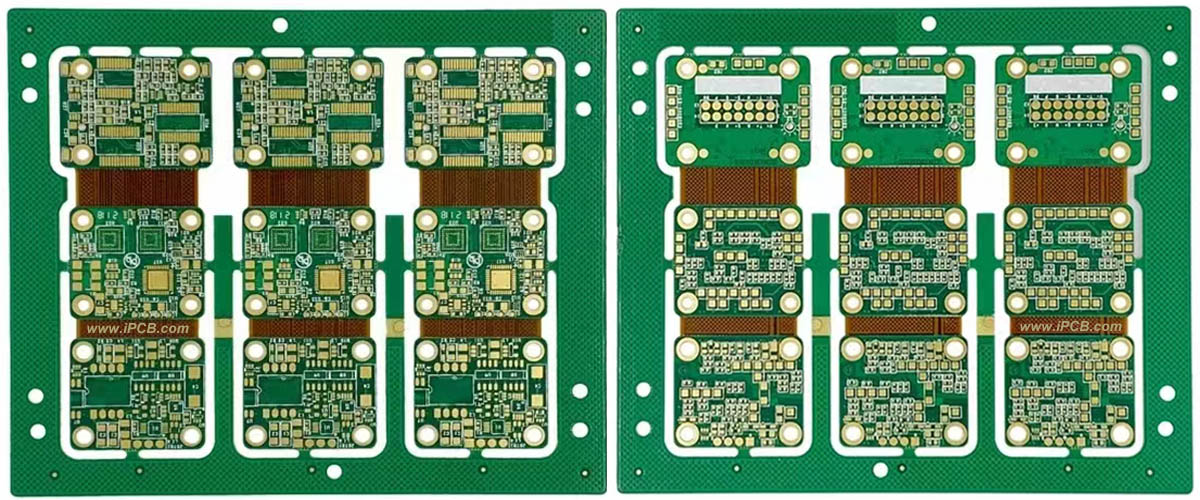

PCB circuit board

The above are the points to note for PCB baking:

1.If the PCB is sealed and unpacked for more than 5 days within 2 months of the manufacturing date, please bake the board at 120±5℃ for 1 hour.

2.If the PCB is over 2 months after the manufacturing date,please bake the board at 120±5℃ for 1 hour before putting it on the line.

3.If the PCB has exceeded the manufacturing date for 2 to 6 months,please bake the board at 120±5℃ for 2 hours before going online.

4.If the PCB is over 6 months to 1 year after the manufacturing date,please bake the board at 120±5℃ for 4 hours before going online.

5.The baked PCB must be used up within 5 days (put into IR REFLOW),than the use of the finished boards need to be baked again for 1 hour before use on the line.

6.If the PCB is over 1 year after the manufacturing date, please bake the board at 120±5℃ for 4 hours before use,and then send it to the PCB factory for re-spraying before use.

Usually before the PCB processing needs to be baked PCB, the need to bake the PCB into the oven, and set the appropriate temperature and time, PCB baking time is generally about 60 minutes to 120 minutes, according to the storage environment and storage time to determine the exact time.

In accordance with the standards of PCB baking, if the PCB production date within 60 days of the case, in the processing before the need for 60 minutes of baking, if the PCB production date of 60 days to 180 days of the need for 120 minutes or so of baking, if the PCB exceeds the date of production of 180 days or more then need to bake the board for 240 minutes or so, if the PCB is seriously exceeded the shelf-life of the application for direct scrapping processing. If the PCB seriously exceeds the warranty period, it will be directly applied for scrap processing.

Long-term storage of PCB for PCBA processing need to bake the board, in order to dry the PCB moisture, to prevent the emergence of burst boards and other conditions in the processing, reducing the circuit board maintenance rate, bake the board will also weaken the internal stress of the PCB circuit board, effectively reducing the probability of PCB deformation,as long as the baking board after the emergence of a little defective phenomenon, may make the appearance of the PCB appears bad, but will not affect the function of the PCB. PCB function.

Comprehensive benefits of the above PCB baking:baking can eliminate the internal stress of the PCB,that is,to stabilise the size of the PCB.After baking the board in the warpage of the board has a relatively large improvement.After baking the board can make the pad in the moisture drying, strengthen the welding effect, reduce the virtual welding, repair rate.