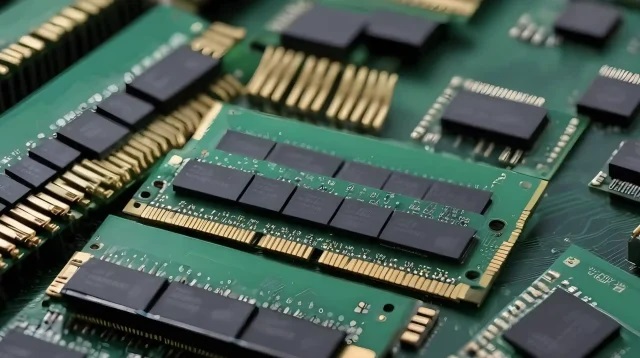

What is a pcb board edge connectors?

In the electronics world, pcb board edge connectors play a vital role in establishing reliable and secure connections between PCBs and external devices. Whether you're working on computers, gaming consoles, or any other electronic device, understanding the importance of pcb board edge connectorss is crucial. This article will delve into the knowledge behind pcb board edge connectorss.

Pcb board edge connectorss act as the interface between a PCB and external devices, providing reliable electrical connections for power, data, and signals. They are specifically designed to mate with the edge of a PCB, making them ideal for applications that require repeated insertion and removal. How should pcb board edge connectorss be designed into a board?

What types of pcb board edge connectors are there?

We have a variety of pcb board edge connectors types to choose from, tailored to different applications. These include:

• Compact PCI (Peripheral Component Interconnect) and SATA

The motherboard PCB features a PCI connector for connecting all computer hardware components. It serves as the bus for all graphics cards, sound, and modem links. PCI enables additional functionality. They consist of rugged pin headers designed to withstand harsh environments.

• Standard Mobile Phones

Mobile phone connectors establish a connection between the phone's battery and the phone's PCB. The edge connector is robust enough to handle the power required for data transmission.

• SIM Card Connector

The SIM card slot in our phones is also an edge connector; we insert the SIM card to establish a network connection with the mobile phone tower.

• Display Connector

Maintains the connection between the display circuitry and the computer's graphics card. The most commonly used is the HDMI connector, which we see in conference rooms with TV-like monitors. We connect it to the HDMI port on our laptops.

• EuroCard Connector

An edge connector, also known as a Euroblock or Euroconnector, is a two-piece connector best suited for signal integrity applications in industrial and communications standards. They are available in types B, C, D, and M. The connector complies with DIN 2 and IEC 41612 standards.

• M2 Expansion Slot

This is a replacement for the mSATA standard. Unlike earlier hard drives, it is not removable. It offers higher data transfer speeds than regular SATA. It is primarily used for ultra-high-speed SSDs in laptops and desktops. An M2 socket has two factors: length and key. These determine the length of the connector slot that can be used within the available space, and the key determines the type of insertion.

Where are pcb board edge connectors primarily used?

Pcb board edge connectors are used across various industries, particularly in telecommunications and computing. Examples include connecting USB or HDMI cables to laptops or PCs, storage devices like SD cards and graphics cards in cameras, and high-speed, high-precision applications in advanced industrial sectors. To ensure performance and durability, pcb board edge connectorss must adhere to strict design guidelines. For example, a minimum clearance of 0.5mm is required between the connector edge and the PCB edge. Surface mount components and pads should be placed at least 2mm away from gold fingers. During the chamfering process, copper removal is required in areas where inner layers are exposed to avoid electrical issues.

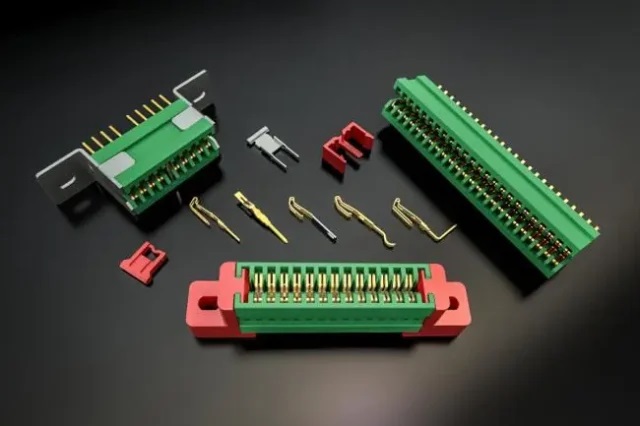

Pcb board edge connectors Design Considerations

Getting the details right when designing pcb board edge connectors is crucial. A well-designed connector ensures smooth performance, durability, and reliability. Green and red board-to-board connectors with exposed pins are key considerations when designing pcb board edge connectors.

The design of a pcb board edge connectors can impact its performance. Here are some important things to consider:

Connector Placement: Connectors should be carefully placed at the edge of the board. Ensure they don't interfere with other components. Learn more about Optimal PCB Component Layout: Mastering Design and Manufacturability.

Pad Spacing: The spacing between gold pads is critical. Too close together, and there's a risk of shorting. Too far apart, and the connection might not be secure.

Copper Removal: In some designs, it may be necessary to remove the copper layer near the connector. This helps prevent electrical interference and ensures a cleaner connection. Learn more about PCB Layer Count and Clearance from Other Components: There should be ample space between the connector and the rest of the PCB.

Why are pcb board edge connectors important?

pcb board edge connectorss are crucial because they help connect components without the need for additional wiring. This makes designs cleaner and more straightforward. Here are a few reasons why they stand out:

High-Speed Data Transfer: pcb board edge connectors can handle fast data, making them ideal for computers and networking equipment.

Durability: Thanks to their gold plating, these connectors can withstand thousands of insertion and removal cycles.

Space Saving: Since they don't require wires, they can remain compact. This is especially important for modern electronic products, where space is limited.

As a service provider specializing in high-end PCB manufacturing, iPCB has extensive experience and mature technology in design compatibility, machining precision, and soldering processes related to pcb board edge connectors. We are committed to providing customers with customized solutions of higher quality and greater precision. Whether it's high-speed signal transmission, complex multi-layer boards, or demanding connector soldering processes, we have extensive experience and technical expertise.