What is PCB board etching?

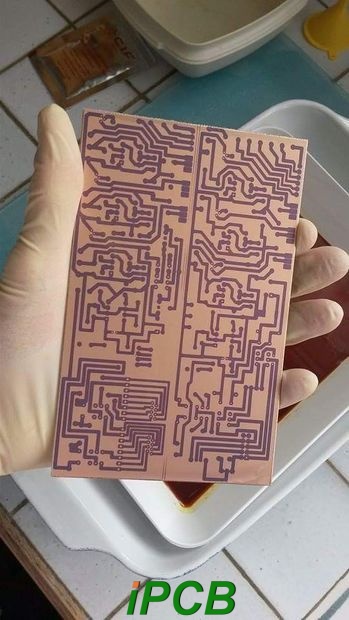

Pcb board etching is a technique for removing unwanted material from a surface and is a critical step in manufacturing printed circuit boards (PCBs), the heart of most electronic devices. This process involves removing unwanted copper from the board to create precise pathways connecting electronic components. Without these pathways, electronic circuits cannot function properly. The precision and quality of the etching process directly impact the performance and reliability of the final product.

The following are different methods of etching:

Ferric Chloride Etching

Ferric chloride etching is one of the oldest and most popular PCB etching methods.

Process Description:

The process begins by cleaning the PCB to remove any contaminants.

The circuit board is coated with a resist material to protect areas that should not be etched.

The board is then immersed in a ferric chloride solution, which reacts with the exposed copper and dissolves it.

After the etching process, the board is washed to remove any remaining ferric chloride and resist material.

Advantages and Applications:

Cost-Effectiveness: Ferric chloride is inexpensive and readily available, making it a popular choice for hobbyists and professional PCB manufacturers.

Efficiency: This method effectively removes copper, providing clear, precise pathways. Applications: It's ideal for low-volume production and prototyping. Due to its affordability, it's also widely used in educational settings and DIY projects.

Ammonium Persulfate Etching

Ammonium persulfate etching is a safer alternative to ferric chloride, providing reliable, high-quality results.

Process Description:

As with ferric chloride, the PCB is first cleaned and covered with a resist material.

The board is then placed in an ammonium persulfate solution to selectively remove exposed copper.

After etching, the board is rinsed to remove any residual chemicals and resist.

Advantages and Applications:

Safety: Ammonium persulfate is less hazardous than ferric chloride, making it safer to handle.

Speed: This etchant works faster, reducing overall processing time.

Applications: Suitable for safety-conscious environments such as schools and small workshops. It is also favored for its speed in producing high-quality PCBs.

Copper Chloride Etching

Copper chloride etching offers high control and precision, making it suitable for etching more complex PCB designs.

Process Description:

The PCB is prepared by cleaning and applying a resistor to protect areas where copper should remain. It is then immersed in a copper chloride solution to remove the exposed copper.

After etching is complete, the circuit board is cleaned to remove any residual etchant and resist.

Advantages and Applications:

Precision: Copper chloride allows for greater control of the etching process, which is crucial for complex designs.

Environmental Impact: If the copper chloride solution is properly regenerated and reused, the method can be more environmentally friendly.

Applications: Ideal for high-density and fine-pitch PCBs, it is often used in advanced electronics and specialized manufacturing environments.

What to Consider During PCB Board Etching?

1. Etching Method:

Immersion and bubble etching methods cause significant undercutting, while splash and spray etching methods produce less undercutting, with spray etching being the most effective.

2. Etching Solution Type:

Different etchants have different chemical compositions, resulting in different etching rates and etching coefficients.

For example, acidic copper chloride etchants typically have an etching coefficient of 3, while alkaline copper chloride etchants can reach a coefficient of 4.

3. Etching Rate:

Slow etching rates can result in severe undercutting. Improving etching quality is closely linked to increasing the etching rate. The faster the etching rate, the shorter the time the substrate spends in the etching solution, the less lateral etching will occur, and the resulting etched pattern will be clearer and more uniform.

4. Etching Solution pH:

Higher pH values in alkaline etching solutions increase lateral etching. To minimize lateral etching, the pH should generally be kept below 8.5.

Etching Solution Density:

Alkaline etching solutions with too low a density will exacerbate lateral etching. Using an etching solution with a high copper concentration is very beneficial for reducing lateral etching.

5. Copper Foil Thickness:

To minimize lateral etching when etching fine lines, it is best to use (ultra-)thin copper foil. Furthermore, the finer the line width, the thinner the copper foil should be. This is because thinner copper foil spends less time in the etching solution, resulting in less lateral etching.

After the etching process, the final product will have circuitry that meets the designer's specifications. Shortly after etching is complete, the circuit board will be further processed for stripping. Stripping removes the electroplated tin or tin/lead or photoresist from the board surface.

During PCB prototyping, any problems with pcb board etching are bound to be widespread, ultimately posing significant quality risks to the product. Therefore, finding the right PCB prototyping manufacturer is crucial. iPCB ensures meticulous control of every step in the PCB prototyping process, delivering high-quality PCB prototypes to our customers. We are dedicated to resolving the pain points faced by companies facing difficulties processing complex, precision, and specialty PCBs. We are a trusted provider of solutions.