PCB design concepts for automotive products:

In the circuit and PCB design stage needs to be combined with the production process,to avoid the design of irregularities caused by the inability to process or new processing difficulties and costs,the most important thing is that if the PCB needs to be re-designed or altered a lot,then in this trial production of the various reliability tests made in the production is meaningless and can not reflect the production requirements of the final product.

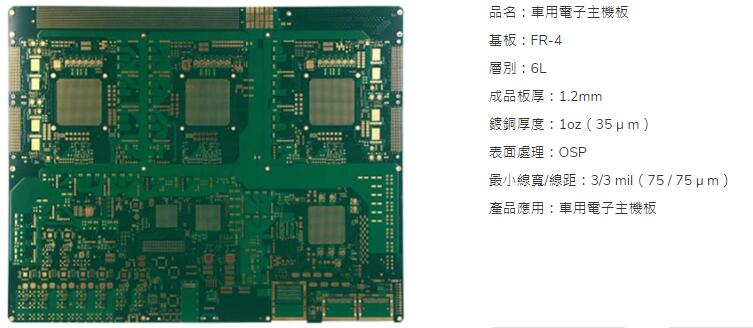

PCBs for automotive products

PCB design requirements for automotive products:

1.Each component must be equipped with detailed specifications in the circuit design need to check whether the device meets the requirements of vehicle regulations,whether there is a lead-free models,PCB design need to check the soldering temperature curve to meet the production requirements,if not to meet the need to find the same specifications of the alternatives,the size of the pad size and component packaging needs to be in accordance with the component manufacturers recommend the size of the do to avoid non-standard design!Avoid irregular design which may cause processing difficulties.

2.The pad size of SMD resistor-capacitor should be enlarged accordingly on the basis of standard,the specific size should be referred to the requirement of files, in order to ensure the welding sufficiently, the requirement of automobile is higher,to avoid the long term vibration which leads to desoldering and virtual welding.

3.The holes and pads of inserted components need to be unified and designed in strict accordance with the manufacturer's specification.If there is no relevant content in the specification, it is necessary to ask the manufacturer to provide the written reference size.

4.The chip aluminium electrolytic capacitors should be placed on the side that is reflowed only once, and if reflowed twice,it will cause damage to the aluminium electrolytic.

5.The gap between the components of reflow soldering process: ≥0.4mm, calculated by the outermost size.

6.Gap between inserted components and chip components: ≥3mm, convenient for manual reflow soldering or partial reflow soldering.

7.Large and heavy components are put on the side of reflow soldering only once to prevent the second reflow soldering from falling off and virtual soldering.

8.Processing technology can not be placed within 5mm of the edge of the component, 3mm can not be placed within the test point, can be aligned but need to be coated with white glaze on the alignment of the protection, to avoid scratching the alignment of the process.

9.The height of the components should be determined according to the processing machine (SMD machine / reflow soldering machine) to determine the maximum range, to avoid the components are too high and can not be processed.

10.Components within 10-20mm near the side of the reflow soldering as much as possible to separate the placement, to avoid too dense due to the components caused by inadequate soldering.

11.Don't put the components with big size close to each other, which will cause the inconvenience of repairing and the uneven heat of reflow soldering to cause the bad soldering.

12.The inserted components should be placed on the same side as far as possible to facilitate the processing.

13.The direction of the components with polarity (aluminium capacitor/tantalum capacitor/diode, etc.) should be arranged in the same direction as much as possible to facilitate visual inspection, if they can not be placed in this way due to the consideration of performance, then the direction should be the same locally.

14.Components should be clearly marked with a bit number, and each board should be written in the same specification, and components of the same type should be the same, so as to facilitate repair and testing.

15.ICT test pads for 0.99mm, each network needs to have a test point, in the circuit design needs to be added, if a local indeed components are too dense and can not place the test point, which requires circuit designers and PCB designers to discuss together to determine which some of the necessary, can not be modified arbitrarily.

16.Need to add glue to fix the components in the circuit design must be marked, so that the PCB design and factory processing staff in the design and processing in advance to consider countermeasures.

17.The soldering surface of the hand-inserted components need to be marked with a white range, so that the operator understands that only in the area of the soldering, but also to facilitate the visual inspection staff to quickly find the location of the inspection.

18.The same components as far as possible on the same side, such as the need for 10 components of the model, do not put 9 on the A side, 1 on the B side, to the patch dosage when the new burden.

19.Do not place components within 4mm of the edge of the V-CUT.

20.Connector selection requirements: easy to insert, but also easy to pull.

21.The thickness of the copper foil of the PCB is 35um, when designing the alignment, we must consider the size of the overcurrent on the line, the principle of designing in accordance with the 1:1 relationship, i.e., current 1A line width of 1mm, in order to ensure the processing, the minimum width of the line is set to 0.2mm, the designer needs to refer to the current consumption file to ensure that they can be aligned above the regulations, the common signal line through the hole 0.4mm, the current is bigger through the hole can be designed to 0.7mm, the design can be made to 0.7mm, and the design can be made to 0.7mm.The common signal line via hole is 0.4mm, while the via hole for higher current can be designed as 0.7mm, and at the same time, multiple via holes can be considered, depending on the current.

22.For the AUDIO part of the ground layout, the tentative 1-point grounding method, although the use of 4-layer board alignment,the second layer of the power, the third layer of the ground, but the ground needs to be handled separately after the part of the audio/tapping part of the ground to connect to the entrance of the total ground, the DSP/CPU and other digital analogue ground separate, to eliminate the arbitrary grounding of the grounding of the low-level method of punching holes.

23.For the display part of the ground layout, must distinguish between the driver IC digital and analogue ground, otherwise it will cause image interference, high-voltage routing attention to distance, to prevent high-voltage fire, signal line attention to the ground mask, to reduce the EMC interference, the use of 4-layer board routing,the second layer of power,the third layer of ground, digital analogue ground separate in the third layer of the ground in the large area.

24.For the front panel, because of the Bluetooth single module, so you can use 2-layer board alignment, as long as the digital analogue ground can be divided, using a large area of grounding method.

25.For the connection board, because only power and other analogue signals, as long as the distinction between the attack and release and other parts can be used, using a 4-layer board alignment, socket part of the shielded copper to reduce EMC.

26.ESD tubes and capacitors for port protection need to be as close to the port as possible,and the protection part of the connector part is as close as possible to the connector pins.

27.P-board and chassis grounding need to consider how to ground sufficiently, the design of screw holes and ground design combined with the consideration, if you do not need to be grounded through the screw in the place, the hole will be independent of the ground, do not need to be designed into the grounding of the main AUDIO and DISPLAY part of the need for careful consideration.

28.Components of the power section of the filter capacitors must be as close as possible to the pin.

29.All P-board thickness of 1.5mm or more,including small module board.

30.2-layer PCB alignment shall not be less than 0.2mm,line spacing is not less than 0.25mm,laying copper spacing is not less than 0.3mm.

31.The alignment of the plug and external interface need to have a test point, so that the workshop analogous inspection to facilitate the work of the thimble.

The above is to share the PCB design requirements of automotive products and PCB design concepts of automotive products.