PCB impedance test standard is to ensure the performance and quality of the PCB board is one of the important aspects of its purpose is to ensure the quality and stability of the signal transmission on the PCB board. Now iPCB provides a detailed explanation of the various aspects of PCB impedance test standards, including the basic concepts of PCB impedance, test methods, standards and practical applications.

What is PCB impedance?

PCB impedance refers to the resistance of a circuit or component to electric current, which consists of resistance, inductance and capacitance. On the PCB board, signal transmission is carried out through copper foil alignment, which can be equated to a series of resistance, inductance and capacitance components. Therefore, PCB impedance of PCB board is an important quota to measure the quality and stability of signal transmission.

PCB impedance test

PCB impedance test methods

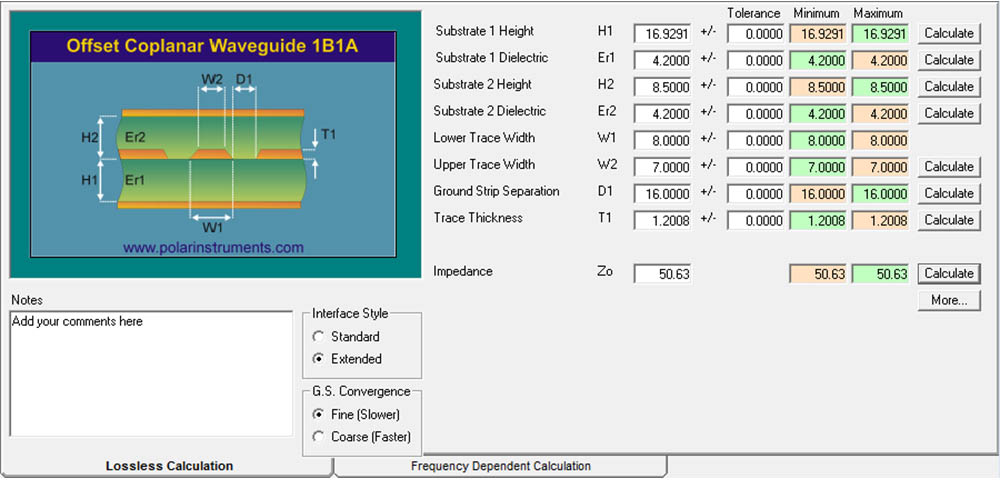

1, the transmission line method: the transmission line method is a commonly used PCB impedance test method, which measures the electrical characteristics of the transmission line on the PCB board to calculate the PCB impedance. Specifically, the transmission line method by measuring the length, width and thickness of the transmission line and other parameters, as well as the height of the transmission line from the ground and other parameters to calculate the PCB impedance.

2, reflection method: reflection method is a way to test the PCB impedance by measuring the degree of signal reflection. The method by sending signals on the signal line on the PCB board, and measure the amplitude and phase of the reflected signal to calculate the PCB impedance.

3, Probe method: Probe method is a probe through the use of direct contact with the signal line on the PCB board to test the PCB impedance method. The method uses high-precision probes and measuring instruments, can quickly and accurately test the PCB impedance.

PCB impedance test standard

Different industries and applications have different PCB impedance test standards. In PCB design, usually use the IPC-2552 standard specification, the specification of the PCB board PCB impedance is divided into five levels, respectively:

1, 25 ohm (low PCB impedance): mainly used for low-frequency signal transmission, such as power supply voltage and ground wire.

2, 50 ohm (standard PCB impedance): mainly used for digital signals and high-speed analog signals.

3、60 ohm (higher PCB impedance): mainly used for audio signal transmission and some specific analog signal transmission.

4、100 ohm (high PCB impedance): mainly used for clock signals and other high-speed digital signal transmission.

5、No level (customized PCB impedance): Users can customize the PCB impedance value according to their own needs.

Practical application of PCB impedance

In PCB design, PCB impedance test is to ensure the quality of signal transmission and stability of one of the important aspects. First of all, in the design stage of PCB boards, it is necessary to determine the required PCB impedance value according to the actual application requirements, and select suitable transmission lines and components to meet the PCB impedance requirements. Secondly, during the PCB manufacturing process, PCB impedance testing is required to ensure that the performance and quality of the PCB meets the standard requirements. Finally, PCB impedance testing is also required periodically during the use of PCBs to monitor signal transmission quality and stability, and to identify and resolve potential problems in a timely manner.

The PCB impedance test standard is one of the most important aspects to ensure the performance and quality of PCB boards. Through the PCB impedance of the basic concepts, test methods, standards and practical application of the detailed description, you can better understand the importance of PCB impedance test in PCB design. In practical applications, it is necessary to determine the required PCB impedance value according to the actual needs, and select the appropriate transmission lines and components to meet the PCB impedance requirements. At the same time, PCB impedance testing is required during the manufacturing and utilization process to monitor the signal transmission quality and stability, and to detect and solve potential problems in a timely manner.