PCBs or printed circuit boards generate heat when current flows through them. Without proper insulation, this heat can cause serious problems for the PCB.

Why do PCBs need to be insulated?

Before understanding PCB insulation, it is important to understand: what is a PCB?

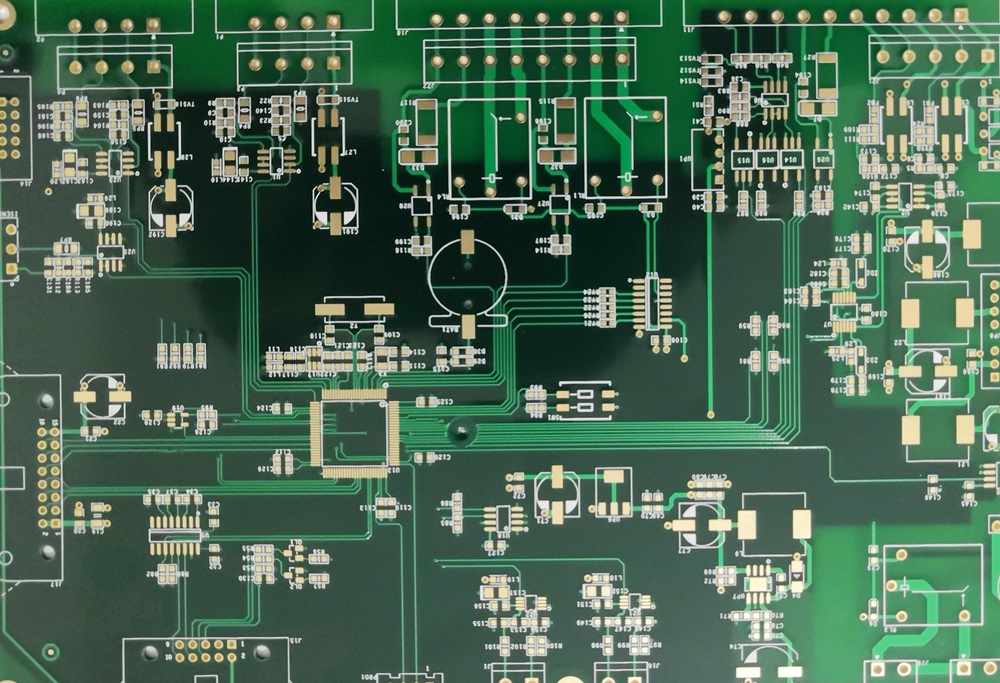

PCBs or printed circuit boards are small green squares (also available in other colors) with copper sheets. They can be found in almost all electronic devices! Printed circuit boards allow electronic devices to work properly, making them a vital but invisible part of everyday life. Without them, computers, telephones, televisions and electronics would not work or would not exist.

Electrical is highly functional for PCBs. PCBs contain printed copper wires, so they naturally conduct electricity. However, electrical components can be dangerous if they are not encapsulated in a non-conductive enclosure or if they become too hot. PCBs must be insulated to prevent corrosion of the copper elements and to minimize accidental contact with conductive materials. Proper insulation can help prevent PCBs from overheating or exploding.

PCB Insulation

There are several ways to insulate a PCB. There are several common insulating materials, but the exact type of insulation usually depends on the application of the PCB design.

PCB Insulation Materials

Common PCB insulation materials are usually formed as non-conductive substrates that can be fused together in multiple layers to allow current to flow correctly throughout the board. Simpler PCBs can be single-sided or single-layered. Complex PCBs (such as those used for high-speed digital communications) may contain more than twenty layers.

To better understand PCB insulation and insulating materials, let's explore the five most common forms of PCB insulation.

FR-2

FR-2 is a low-grade flame retardant laminate option. It is a composite material made of paper and plasticized phenolic resin, making it both lightweight and durable. This material is commonly used for single-sided circuit boards. FR-2 is halogen-free, non-hydrophobic, and can be easily stamped or milled. FR-2 is one of the least expensive options for PCB insulation, and is a common choice for companies that manufacture disposable consumer electronics.

FR-4

FR-4 is a premium flame retardant laminate option. It is a composite material made of braided fiberglass and is commonly used in the manufacture of double-sided and multilayer PCBs. FR-4 can withstand higher temperatures and physical stresses than FR-2. It is also an affordable material, making it a popular choice for manufacturers of high-end consumer electronics. FR-4 is not very fast to machine and requires milling, stamping or machining tungsten carbide tools.

RF

RF substrates are designed to allow PCBs to operate in applications that use high power RF and microwaves. RF substrates are most commonly used for PCBs installed in military electronics, avionics and avionics.

However, it is important to note that there are some consumer electronics products that contain this type of substrate. The plastics that make up a typical RF substrate do not create a lot of insulation, and they perform well when tasked with generating high currents. RF and microwave PCBs usually have only one or two layers.

Flexibility

Although most printed circuit boards are flat and rigid, there are some innovative PCBs that can bend in almost any direction without breaking. Flexible circuits require a similar but unique form of insulation. Flexible circuits are usually protected with PCB insulation spray, in addition to plastic film being a popular choice. Flexible circuits require thin, strong PCB insulation coatings so that they can move freely and fit into tight, confined spaces.

Metal

Choosing metal as an insulator may seem strange. Metals are usually electrically conductive, and accidental conductivity can lead to PCB failure, misfire or melting. However, in some cases it may be more advantageous for the PCB to have a metal substrate. Metal is an excellent conductor of heat and can withstand large currents without cracking or burning. PCBs installed in powered devices that consume large amounts of electricity may require a metal substrate to function effectively.

To prevent the PCB from overheating, catching fire or catching fire, it must be adequately insulated. The type of insulating material corresponds to the type of use the PCB provides.

General-purpose electronic PCBs are suited to simpler, more cost-effective FR-2 or FR-4 substrates. RF substrates, on the other hand, are more suitable for applications involving high power RF. Flexible substrates such as plastics are well suited to meet the insulation needs of flexible circuit boards. Metals, on the other hand, maintain excellent thermal conductivity while keeping power electronics cool. As you can see, substrate insulation is an important thing.