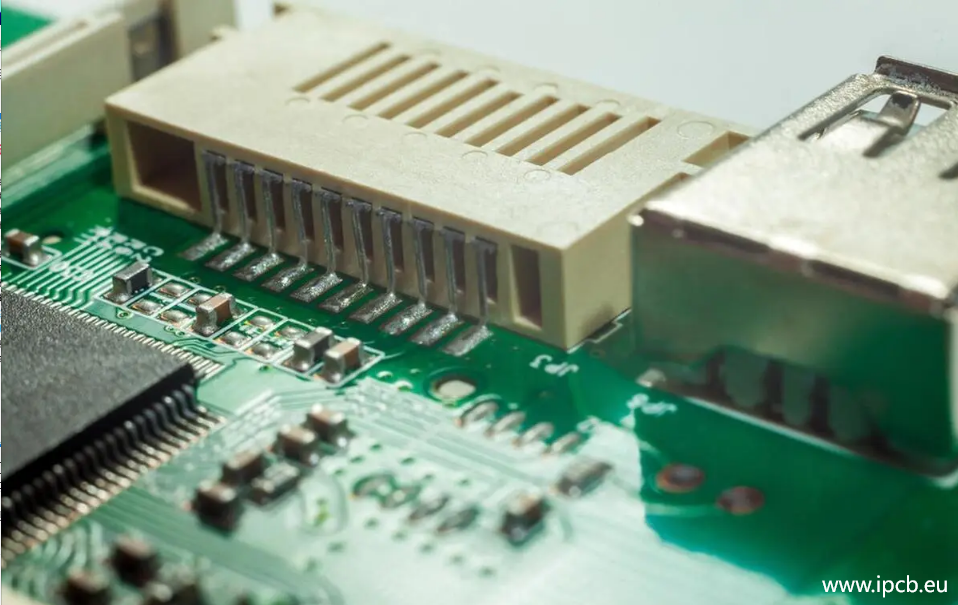

PCB pin soldering Technology is the process of connecting pins (also called pins or leads) to a printed circuit board (PCB). Pins are often used to make electrical connections with other devices or connectors, such as connecting switches, sensors, displays, etc. in electronic devices.

In the field of electronic engineering and manufacturing,PCB pin soldering technology is the basis for connecting and assembling important components. Although the previous basic steps have introduced the process of simple soldering,it is very necessary for professionals to deeply analyze the details and complexity of this process. The following content will explore issues such as material science, thermal management, soldering defects,and quality control in the soldering process.

Soldering PCB pins is the process of connecting pins to a printed circuit board (PCB). Here are some basic steps:

1.Preparation: Make sure you have the right pins and PCB, and choose the right pin type and size according to the design requirements.

2.Material preparation: In addition to the pins and PCB, you will also need solder wire, soldering pen, tweezers or other appropriate tools.

3.Positioning the pins: Place the pins in the correct position on the PCB. Make sure the pins are aligned with the holes on the PCB.

4.Soldering preparation: Preheat the solder wire and apply it to the junction of the pins and the PCB pads. This helps improve the quality and reliability of soldering.

5.Soldering the pins: Using a soldering pen or appropriate tool, bring the solder wire into contact with the pins and PCB pads, heat the solder to melt it and form a solid connection.

6.Check the solder joints: After completing the soldering, check whether the solder joints are smooth and uniform and there are no short circuits or cold soldering. If there are problems, you can use a soldering iron to reheat the solder joints to repair them.

7.Cleaning: After soldering is complete, clean off any excess solder wire or solder slag. Make sure the area around the solder joint is clean and tidy.

PCB pin

1.Material Science

1.1Selection of solder alloys

Solder generally includes metals such as tin (Sn), lead (Pb), silver (Ag), and copper (Cu). Commonly used alloys are:

Sn-Pb alloy: This alloy is widely used in the welding industry and has good fluidity and wettability. The typical ratio is 63Sn/37Pb, and the melting point is about 183°C.

Lead-free solder: With the change of environmental regulations, lead-free solder (such as SAC alloy, which contains tin, silver and copper) has become more and more popular. Its melting point is usually between 217°C and 230°C. Although its fluidity is slightly poor, its environmentally friendly properties make it the first choice for many applications.

1.2 The influence of PCB materials

Different PCB materials (such as FR-4, polyimide, etc.) will affect the performance and results of welding. FR-4 is the most common PCB substrate with good mechanical properties and insulation properties, but its heat resistance should also be paid attention to during welding to avoid interlayer peeling.

2.Thermal management

Thermal management during welding is critical. Excessive temperature and heating time may cause damage to the PCB or Component.

2.1 Temperature control

The temperature of the soldering iron should be adjusted according to the type of solder. The "preheating" stage can be used to reduce the difference in heat absorption between components and PCBs. Using a thermometer or thermal imager can effectively monitor the welding temperature to ensure that it is operated within a safe range.

2.2 Heat conduction during welding

A soldering point with good contact can effectively conduct heat, while poor contact will cause heat concentration, forming "hot spots" that may affect the quality of the solder joint. During the soldering process, ensure good contact between the soldering iron and the component pins to improve thermal efficiency.

3.Analysis of soldering defects

Understanding and identifying soldering defects is very important for professional soldering.Common defects include:

3.1 Cold Joint

A cold joint is caused by insufficient temperature during soldering, resulting in insufficient solder joint strength, which may be affected by vibration or thermal cycling and cause poor connection. It is recommended to use flux and appropriate heating coils to prevent this.

3.2 Solder joint cracking

Solder joint cracking is usually caused by factors such as thermal stress, mechanical stress or thermal expansion. When designing, the physical layout and stress distribution of the solder joint should be taken into account.

3.3 Solder Drag

Drag soldering is excessive flow of solder during soldering, resulting in poor solder joint formation. Proper control of the amount of solder is the key to preventing this defect.

4.Quality Control

High-quality welding not only depends on the skills of technicians, but also requires a systematic quality control program.

4.1 Welding Process Specifications

Develop detailed welding process specifications and record the parameters of each welding step, including temperature, time and materials used, to ensure that standards are met during the production process.

4.2 Welding Review and Testing

Regular welding review and testing, using non-destructive testing methods such as X-ray inspection and ultrasonic testing, can help detect welding quality problems.

4.3 Feedback and Improvement

Establish an effective feedback mechanism to collect problems that occur during the welding process in a timely manner and analyze and improve them. Such continuous improvement can improve the overall welding quality.

PCB pin soldering technology is a complex technical task that requires a deep understanding of materials science, thermal management, welding defects and quality control. By combining each aspect, professionals can continuously improve welding quality in practice and ensure the reliability and performance of electronic products. In the rapidly developing electronics industry, superb welding technology is not only a reflection of personal skills, but also an important guarantee of product quality.