In pcb design and manufacturing, pcb substrate thickness is a crucial factor affecting electrical performance, mechanical properties, and manufacturing processes. As electronic devices move towards higher density, higher speed, and higher reliability, the appropriate selection of PCB substrate thickness not only impacts the electrical performance and heat dissipation capabilities of the circuit board but also directly relates to the assembly and lifespan of the entire device.

Choosing the right PCB substrate thickness is not just about a number; it involves a comprehensive consideration of design, electrical performance, mechanical strength, and manufacturing processes. Different PCB thicknesses directly affect product reliability, cost, and manufacturing difficulty, so careful evaluation is essential during the design phase.

pcb substrate thickness

Key Factors at the Design Level

1. Copper Thickness and Current Carrying Capacity

The copper layer thickness directly determines the current carrying capacity of the circuit. Thicker copper allows for higher current, but also increases the overall board thickness. High-power power supplies or industrial control boards typically require 2 ounces or thicker copper, while ordinary digital circuits only need 1 ounce. The design must consider current requirements, trace width, and heat dissipation conditions to ensure both electrical performance and assembly requirements are met.

2. Prepreg Thickness and Number of Layers

Prepreg is used for bonding in multilayer boards, and its thickness and dielectric properties affect board thickness and signal performance. Single-layer boards are relatively thin, while each additional layer in a multilayer board increases the copper and prepreg, thus increasing the total thickness. In high-speed signal board design, board thickness must also consider impedance matching and signal integrity.

3. Mechanical and Environmental Requirements

Thicker boards provide higher mechanical strength and thermal stability, suitable for applications subject to vibration, shock, or high temperatures, such as industrial control, automotive electronics, and power boards.

Key Factors at the Manufacturing Level

1. Drilling Limitations

The drilling depth and hole diameter ratio affect PCB substrate thickness. Thicker boards require longer drill bits, resulting in reduced drilling accuracy, increased tool wear, and potential hole wall damage or displacement. Manufacturers usually address this issue by optimizing drilling parameters or using multi-stage drilling.

2. Copper Layer and Process Complexity

Thick copper boards increase the difficulty of etching, copper plating, and lamination. Thick copper requires multiple etching steps to ensure trace width accuracy, and lamination also requires higher temperatures and longer times. Thicker PCBs have higher production costs and manufacturing difficulties than standard boards, requiring communication with the manufacturer during the design phase.

PCB substrate thickness is one of the important factors to consider when manufacturing printed circuit boards, as it affects conductivity, resistance, and PCB performance. There is no single standard for circuit board thickness in the PCB industry, but some thicknesses are preferred and commonly used by many manufacturers.

What is the standard PCB substrate thickness?

The most common PCB thickness for FR-4 printed circuit boards is 1.57 mm (0.062 inches). This is the most widely used PCB thickness in the industry and is usually the default thickness offered when using FR-4 substrates.

However, with technological advancements and increasingly complex circuits, the number of layers increases, and so does the copper weight. This has led to some more common PCB thickness options, including 93 mils (2.36mm) and 125 mils (3.17mm).

PCB substrate thickness refers to the thickness of the finished printed circuit board. The thickness of a PCB mainly depends on factors such as the number of layers, copper thickness/weight, the substrate used, and the operating environment. When discussing standard PCB thickness, there is no official standard. However, certain sizes are preferred and have become standard practice for PCB manufacturing companies.

Most PCB manufacturers can manufacture boards with custom thicknesses; however, this has its drawbacks and challenges. Most of their equipment is already calibrated to a specific set of fixed thickness options. Using a custom thickness may require them to adjust their equipment to accommodate specific requirements. This can be done, but it will result in higher costs and longer turnaround times.

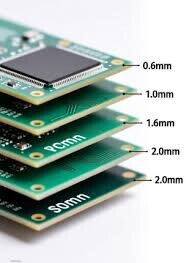

1. Conventional thicknesses: 1.0mm, 1.6mm, 2.0mm

These thicknesses are commonly used for general applications such as consumer electronics, smart homes, and industrial control. These applications do not require particularly high mechanical strength or conductivity, so traditional PCB substrate thickness can be used.

pcb substrate thickness

2. Ultra-thin board thicknesses: 0.4mm, 0.6mm

These ultra-thin board thicknesses are typically used in lightweight and miniaturized electronic products such as smartwatches, smart glasses, and smart wearable devices. These products require very light PCBs, so using ultra-thin PCB thicknesses can meet the requirements. 3. High-Strength Board Thickness: 2.4mm, 3.0mm

These high-strength board thicknesses are typically used in industrial and military applications such as aerospace, rail transportation, and military equipment. These applications require PCBs with high mechanical strength and durability, and therefore, using PCBs with high-strength board thicknesses can meet these requirements.

In summary, the choice of circuit board thickness needs to be determined based on specific application requirements. When selecting the thickness of a PCB board, multiple factors such as mechanical strength, conductivity, and cost need to be considered to ensure the performance and reliability of the PCB. At the same time, attention should be paid to the thickness limitations of the PCB board to ensure that the designed PCB can be manufactured and assembled.

Balancing Thickness and Cost

Increasing the thickness of the PCB substrate not only affects performance but also leads to a significant increase in cost, which needs to be carefully considered during the design phase. This is mainly reflected in the following aspects:

1. Material Costs

The price of the board material itself increases with thickness, especially for thick copper boards or high-performance multilayer boards. Increased copper layer thickness also directly increases material costs. For high-power or industrial control applications, thick copper is necessary, but for projects with limited budgets, the match between thickness and function needs to be carefully evaluated.

2. Manufacturing Costs

Thicker boards are more difficult to process in lamination, drilling, etching, and testing. Thick copper boards may require multiple etching steps to ensure line width accuracy, and increased drilling depth can easily cause defects in the hole walls, requiring higher precision drilling equipment and strict process control. Therefore, labor, equipment, and quality inspection costs also increase accordingly.

3. Transportation and Assembly Costs

Thicker boards are usually heavier than thinner boards, requiring higher demands on packaging, transportation, and assembly. Especially for large-sized or multi-layer thick boards, additional protective measures may be needed during handling and fixing, increasing indirect costs.

4. Comprehensive Consideration of Cost and Performance

When choosing PCB substrate thickness, it is necessary to consider not only electrical performance and mechanical strength but also reliability and cost. A reasonable design should avoid unnecessary excessive thickening while ensuring performance, achieving a balance between performance and cost. For example, for signal boards, excessively thick copper and substrate may not significantly improve signal integrity, while the cost increases significantly.

PCB substrate thickness is a core factor affecting the performance, reliability, and production cost of electronic products. The appropriate selection of board thickness requires comprehensive consideration of electrical performance, mechanical strength, thermal management, manufacturing processes, and cost factors. In the future, with the development of high-density, high-power, and intelligent electronic products, PCB substrate thickness design will continue to play an irreplaceable and crucial role, providing a solid foundation for overall system performance and reliability.