During PCB manufacturing, the manufacturing process maintains a specified thickness. Because the required thickness depends on the application and function of the board, the thickness can vary depending on the PCB design. PCB manufacturing involves multiple manufacturing processes, and the methods used to achieve the final PCB thickness, including tolerance levels, can vary.

PCB design engineers primarily determine PCB thickness based on the PCB's intended use. PCB thickness affects the PCB's price, performance, and quality, among other factors.

1. PCB Price and Costs

A major component of a PCB quote is material cost. If a customer consistently receives boards thicker than specified by the specifications and tolerances, the PCB manufacturer has used more material than it was paid for, resulting in a loss for the manufacturer. Conversely, if a customer consistently receives thinner boards within their specifications and tolerances, they will pay the manufacturer more than the agreed-upon price. For a single board or prototype, the material cost of deviating from the specified tolerance may not be significant. However, for large-scale production runs, the material cost involved can be significant.

2. PCB Performance

Using thinner PCBs instead of thicker ones can result in significant performance degradation. Thinner PCBs can crack when subjected to vibration in the application. On the other hand, thick boards may not fit properly in thin devices, leading to assembly and performance issues.

3. PCB Quality

PCBs that deviate from the specified thickness may be rejected during the manufacturer's circuit quality inspection. Customers may also reject such PCBs during incoming quality inspection.

PCB Thickness

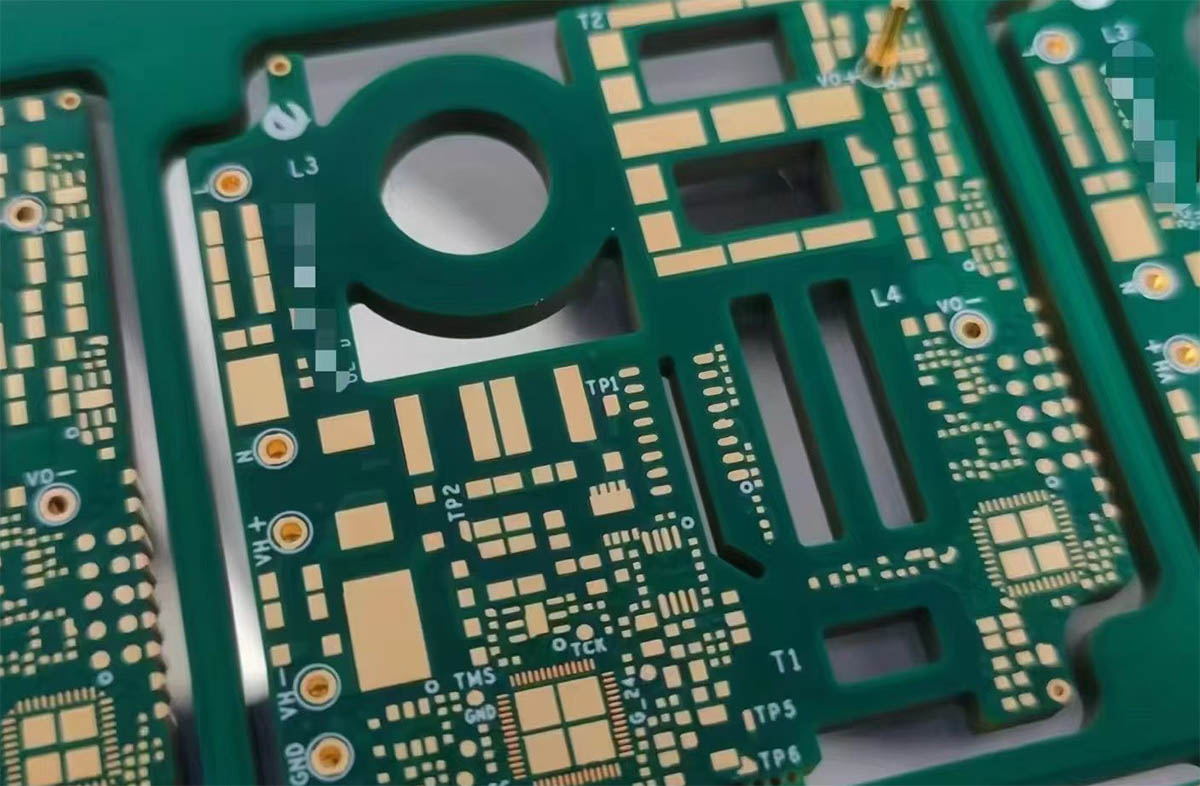

PCB Thickness Analysis

Simple PCBs, whether single- or double-layer, are typically built around a single core or copper-clad laminate. For multi-layer boards, consider a double-layer core with multiple layers of prepreg and copper foil stacked symmetrically around it. More complex boards may have numerous cores.

Thus, the cumulative thickness of the core plus the individual thicknesses of all layers constitute the final thickness of the board. The standard thickness for industrial PCBs is 1.57 mm (63 mils). However, thicknesses can range from 0.2 mm to 6 mm.

While the core, prepreg layers, and copper foil layers constitute the majority of the PCB thickness, the outermost surface of the PCB may also have solder mask and silkscreen layers that increase the board thickness. For example, a 1.57 mm (63 mil) thick, two-layer PCB might have a 1.5 mm (59 mil) core, two 0.035 mm (1.38 mil) copper layers, two 0.01 mm (0.394 mil) solder mask layers, and one or two 0.006 mm (0.226 mil) silkscreen layers.

Modern PCB manufacturers provide standard thicknesses based on the number of layers in the PCB. For example, the standard thickness for a four-layer PCB is 0.8 mm ± 10%, while the standard thickness for a six-layer PCB is 0.8 mm ± 10% or 1.6 mm ± 10%. Similarly, the standard thickness for an eight-layer board is 1.6 mm, 2.4 mm, or 3.2 mm ± 10%.

PCB Core Thickness

The core, or substrate, of a PCB typically consists of epoxy-glass fiber and copper foil bonded to both sides. Different core thicknesses are available, as well as different copper foil thicknesses. The rigidity of a PCB comes from its substrate. As circuit complexity increases, PCB designers require multiple layers to interconnect the large number of SMDs on a board. Consequently, manufacturers must increase the standard PCB thickness from 1.6 mm to 2.4 mm. To comply with RoHS and WEEE requirements, PCB manufacturers must use high-temperature-resistant substrate materials, such as Isola 370HR, with multiple layers in thicknesses of 0.2, 0.3, 0.4, 0.6, and 1.0 mm.

PCB Prepreg Thickness

PCB manufacturers create prepregs, which are made by impregnating fiber fabric with an adhesive resin. iPCBs use this prepreg to bond etched cores. Heat and pressure are used to achieve this, varying the thickness of the prepreg layers and adjusting it to the final thickness of the board.

PCB Copper Thickness

Depending on the current processing requirements of the board, its copper layer thickness can vary between 0.036 mm and 0.07 mm. Typically, iPCBs use the same copper thickness on both sides of the core layer to prevent the board from warping due to heat during assembly.

How to Choose PCB Thickness?

While most designers prefer standard thickness boards, some may require a custom thickness for their specific application. During the final stages of design, the choice of board thickness influences several factors.

Weight: The thicker the board, the heavier it is. For lightweight devices, PCB designers must look for materials that can produce thin, light PCBs.

Flexibility: Many modern devices require flexible PCBs. Since thick boards are often inflexible, designers may have to consider using thin, flexible boards.

Space Constraints: With the growing demand for ultra-thin devices, space is always a constraint. Designers must use low-profile components on thin boards.

Components and Connectors: Heavy components require a thick board to support them without bending or sagging. A thin board can only support small, minimal components. For large, multi-pin components like BGAs, PCB designers must pay special attention to board thickness.

Impedance: The specific dielectric material that makes up the pre-preg will provide a certain impedance and thickness. If designers must vary the thickness while maintaining impedance, they must use a different dielectric material.

Specific PCB applications require a specific thickness to function properly. Thickness defines the board's mechanical rigidity, signal integrity, and the current-carrying capacity of its copper traces. Most PCB engineers and manufacturers follow IPC standards when specifying board thickness and its tolerances for a particular application.